Suzuki Grand Vitara JB627. Manual - part 131

2C-16 Rear Suspension:

Assembly

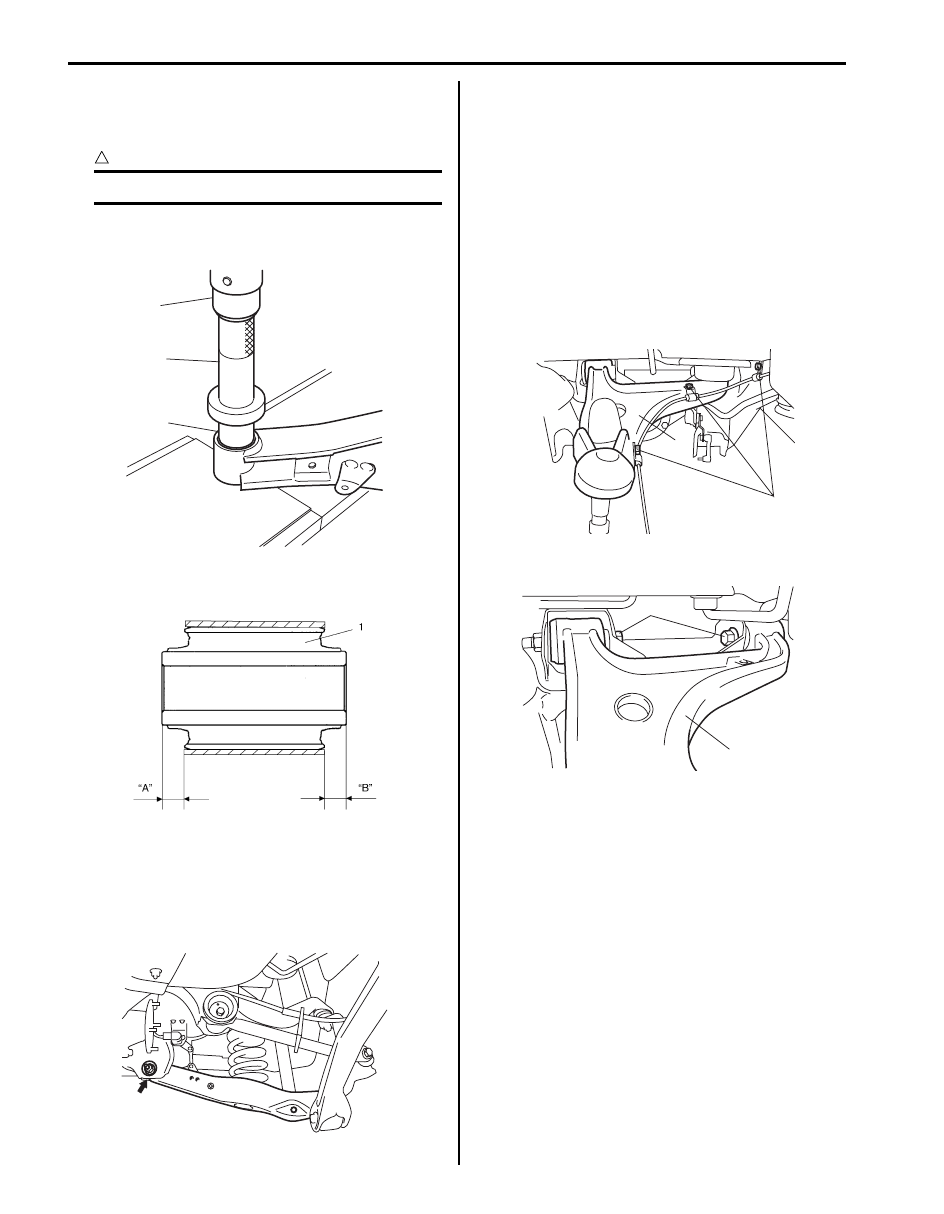

1) Press-fit suspension lateral link bushing (2) by using

press (1) and special tool.

CAUTION

!

Be sure to use new bushing.

Special tool

(A): 09913–85210

2) Press-fit bushing (1) so that dimension “A” and “B” in

figure become equal.

Lower Arm Check

S6JB0B2306016

• Inspect for cracks, deformation or damage.

• Inspect bushing for wear and breakage.

If any faulty condition is found, replace.

Upper Arm Removal and Installation

S6JB0B2306017

Removal

1) Hoist vehicle and remove rear wheels.

2) Remove control rod refer to “Control Rod Removal

3) Remove trailing rod refer to “Trailing Rod Removal

4) Remove lower arm refer to “Lower Arm Removal and

5) Remove rear suspension knuckle refer to “Rear

Suspension knuckle Removal and Installation”.

6) Remove wheel sensor bolts (1) from upper arm (2).

7) Remove upper arm bolts (1) and then upper arm (2).

1

(A)

2

I5JB0A230083-01

I5JB0A230037-02

I5JB0A230038-01

1

2

I5JB0A230039-01

1

2

I5JB0A230040-01