Suzuki Grand Vitara JB627. Manual - part 118

1J-13 Charging System:

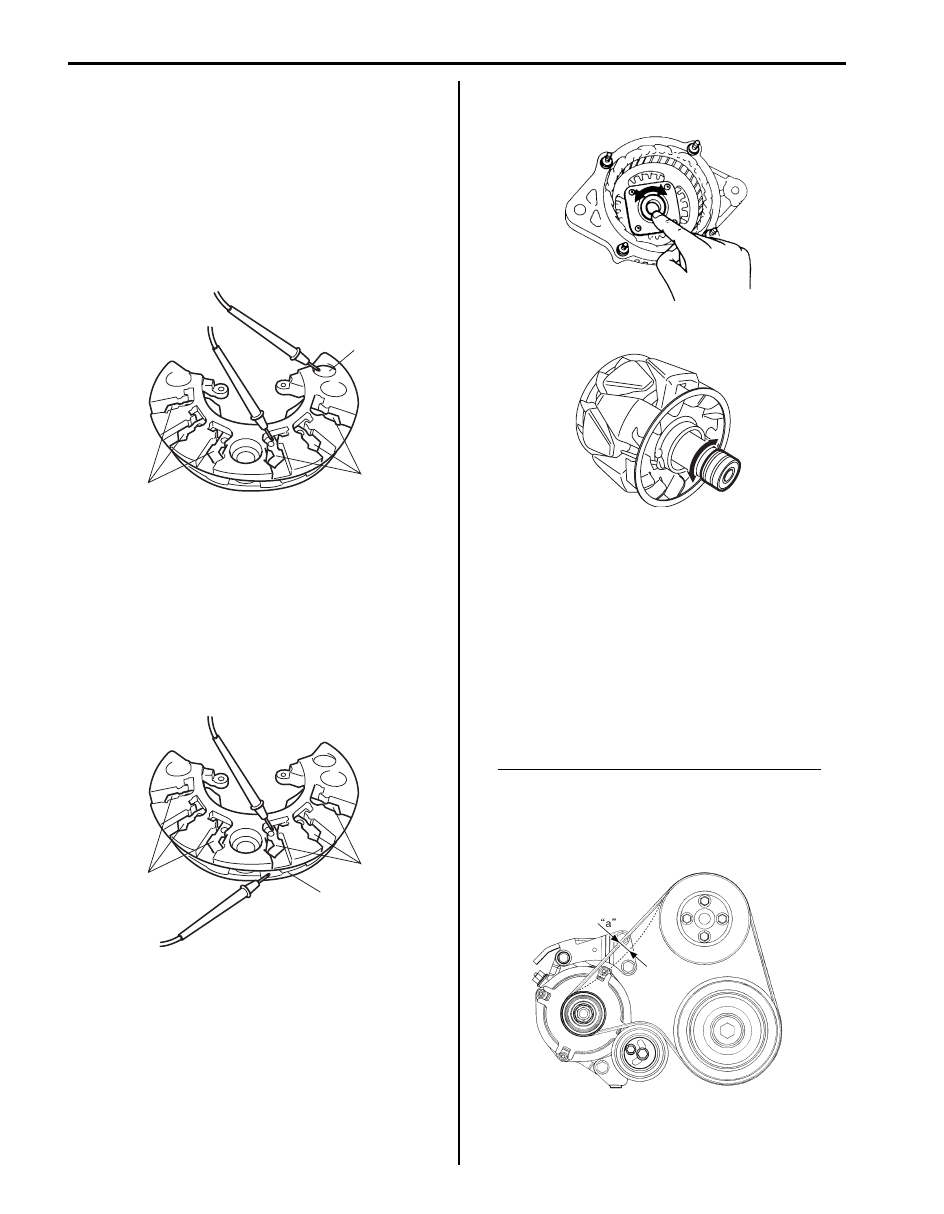

Rectifier

Positive rectifier

1) Using an ohmmeter, connect one tester probe to the

“B” terminal (1) and the other to each rectifier

terminal (2).

2) Reverse the polarity of the tester probes and repeat

Step 1).

3) Check that one shows continuity and the other

shows no continuity. If there is continuity, replace the

rectifier.

Negative rectifier

1) Using an ohmmeter, connect one tester probe to

negative terminal (1) and the other to each rectifier

terminal (2).

2) Reverse the polarity of the tester probes and repeat

Step 1).

3) Check that one shows continuity and the other

shows no continuity. If there is continuity, replace the

rectifier.

Bearing

• Check that drive and bearing is not rough or worn.

• Check that end housing bearing is not rough or worn.

Water Pump and Generator Drive Belt

Inspection and Adjustment

S6JB0B1A06007

1) Disconnect negative cable at battery.

2) Inspect belt for cracks, cuts, deformation, wear and

cleanliness. If it is necessary to replace belt, refer to

“Water Pump and Generator Drive Belt Removal and

Installation”.

3) Check belt for tension. Belt is in proper tension when

it deflects the following specification under thumb

pressure (about 10 kg or 22 lb.).

Water pump / generator drive belt tension “a”

Existing belt: 9.0 – 10.0 mm (0.35 – 0.39 in.) as

deflection / 10 kg (22 lbs)

New belt: 7.5 – 8.5 mm (0.29 – 0.33 in.)as

deflection / 10 kg (22 lbs)

1

2

2

I6JB011A0024-01

2

2

1

I6JB011A0025-01

IYSQ011A0050-01

I6JB011A0026-01

I6JB011A0027-01