Suzuki Grand Vitara JB627. Manual - part 79

1C-14 Engine Electrical Devices:

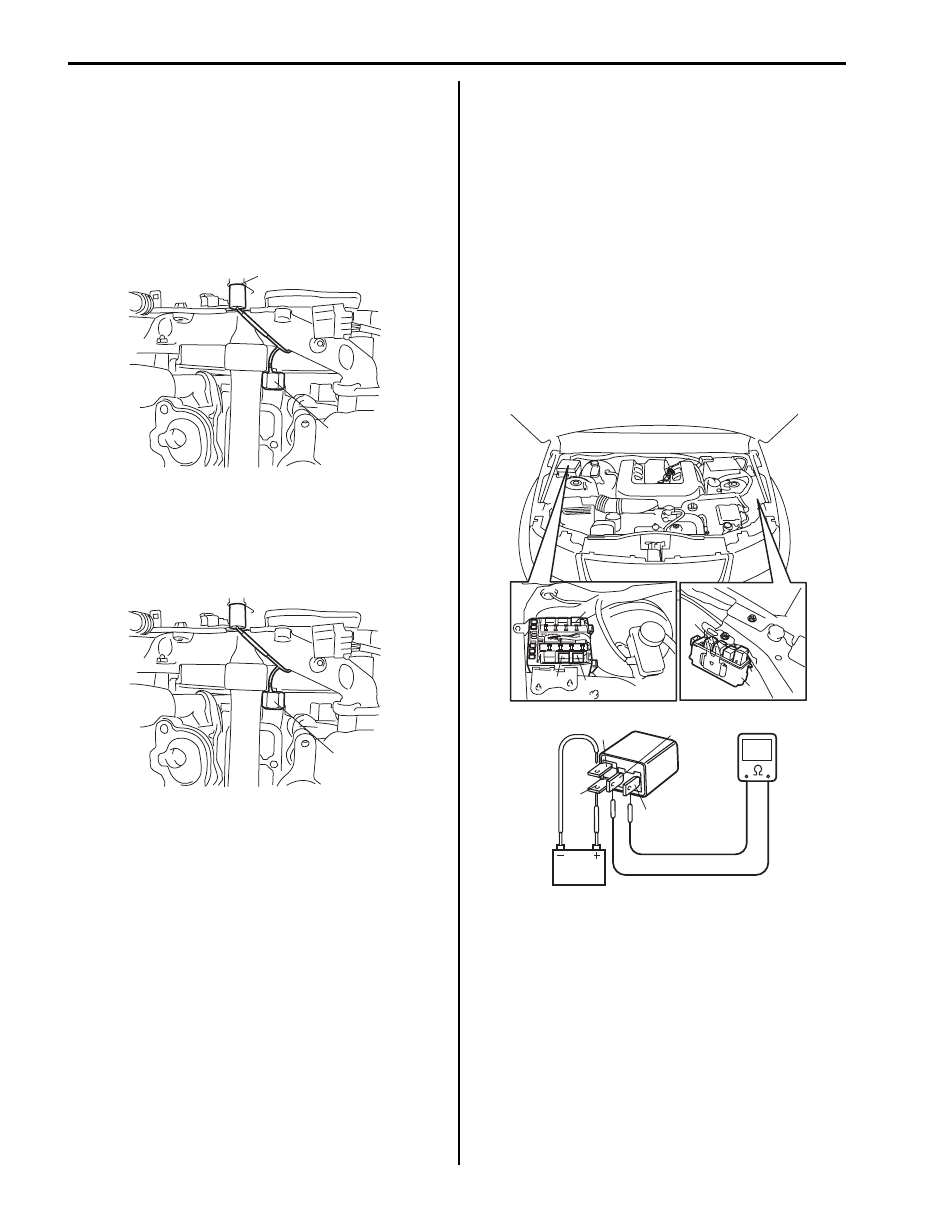

Knock Sensor Removal and Installation

S6JB0B1306020

Removal

1) Disconnect negative cable at battery.

2) Remove intake manifold from cylinder head referring

to “Intake Collector and Intake Manifold Removal

and Installation in Section 1D”.

3) Disconnect knock sensor connector (1).

4) Remove knock sensor (2) from cylinder block.

Installation

Reverse removal procedure for installation.

Tightening torque

Knock sensor (a): 22 N·m (2.2 kgf-m, 16.0 lb-ft)

Engine and Emission Control System Relay

Inspection

S6JB0B1306021

Main, Fuel Pump, Starting Motor Control and

Throttle Actuator Control Relays (Single Type Relay)

1) Disconnect negative cable at battery.

2) Remove main relay (1), fuel pump relay (3), starting

motor control relay (2), throttle actuator control relay

(4) from fuse box No.2 (5) and/or relay box (6).

3) Check that there is no continuity between terminal

“C” and “D”. If there is continuity, replace relay.

4) Connect battery positive (+) terminal to terminal “B”

of relay. Connect battery negative (–) terminal to

terminal “A” of relay. Check for continuity between

terminal “C” and “D”. If there is no continuity when

relay is connected to the battery, replace defective

relay.

1

2

I6JB01130025-01

(a)

I6JB01130026-01

“D”

“B”

“A”

“C”

1

3

2

4

6

I5JB0C130001-01