Suzuki Grand Vitara JB627. Manual - part 78

1C-10 Engine Electrical Devices:

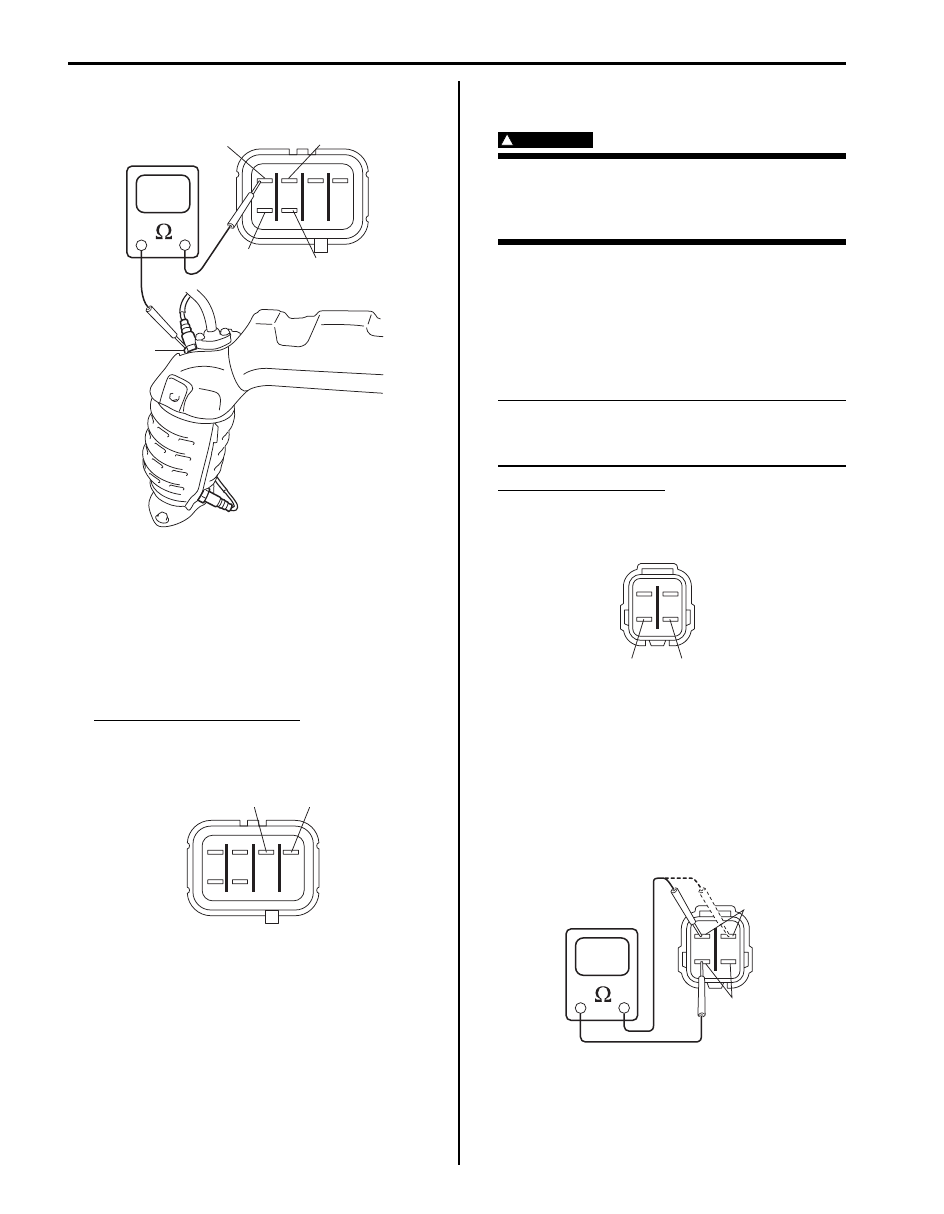

• Between each terminal ((1), (2), (3) and (4)) of A/F

sensor and A/F sensor body (5).

3) Connect A/F sensor connector securely.

Adjusting Resistor (If Equipped)

1) Disconnect A/F sensor connector.

2) Using ohmmeter, measure resistance of adjusting

resistor between terminals “R+” and “R–” at A/F

sensor connector.

If found faulty, replace A/F sensor.

Adjusting resistor resistance

100 – 58000

Ω at 20 °C (68 °F)

Viewed from terminal side

3) Connect A/F sensor connector securely.

Heated Oxygen Sensor (HO2S-2) Heater On-

Vehicle Inspection (If Equipped)

S6JB0B1306014

WARNING

!

To avoid danger of being burned, do not

touch exhaust system when system is hot.

Sensor inspection should be performed

when system is cool.

Heater

1) Disconnect sensor connector.

2) Using ohmmeter, measure resistance of sensor

heater between terminals “V

B

” and “GND” at sensor

connector.

If found faulty, replace oxygen sensor.

NOTE

Temperature of sensor affects resistance

value largely. Make sure that sensor heater is

at correct temperature.

HO2S heater resistance

5.0 – 6.4

Ω at 20 °C (68 °F)

Viewed from terminal side

3) Connect sensor connector securely.

Circuit Insulation Check

1) Disconnect connector from HO2 sensor.

2) Using ohmmeter, check circuit insulation of HO2S

sensor. If faulty is found, replace HO2S sensor.

• Between each heater terminal (1) and other than

heater terminals (2).

Viewed from terminal side

1

2

3

4

5

I6JB01130035-01

“R+”

“R

−

”

I5JB0A130002-02

“GND”

“V

B

”

I5JB0A130024-03

1

2

I6JB01130036-01