Suzuki Grand Vitara JB627. Manual - part 68

1A-221 Engine General Information and Diagnosis:

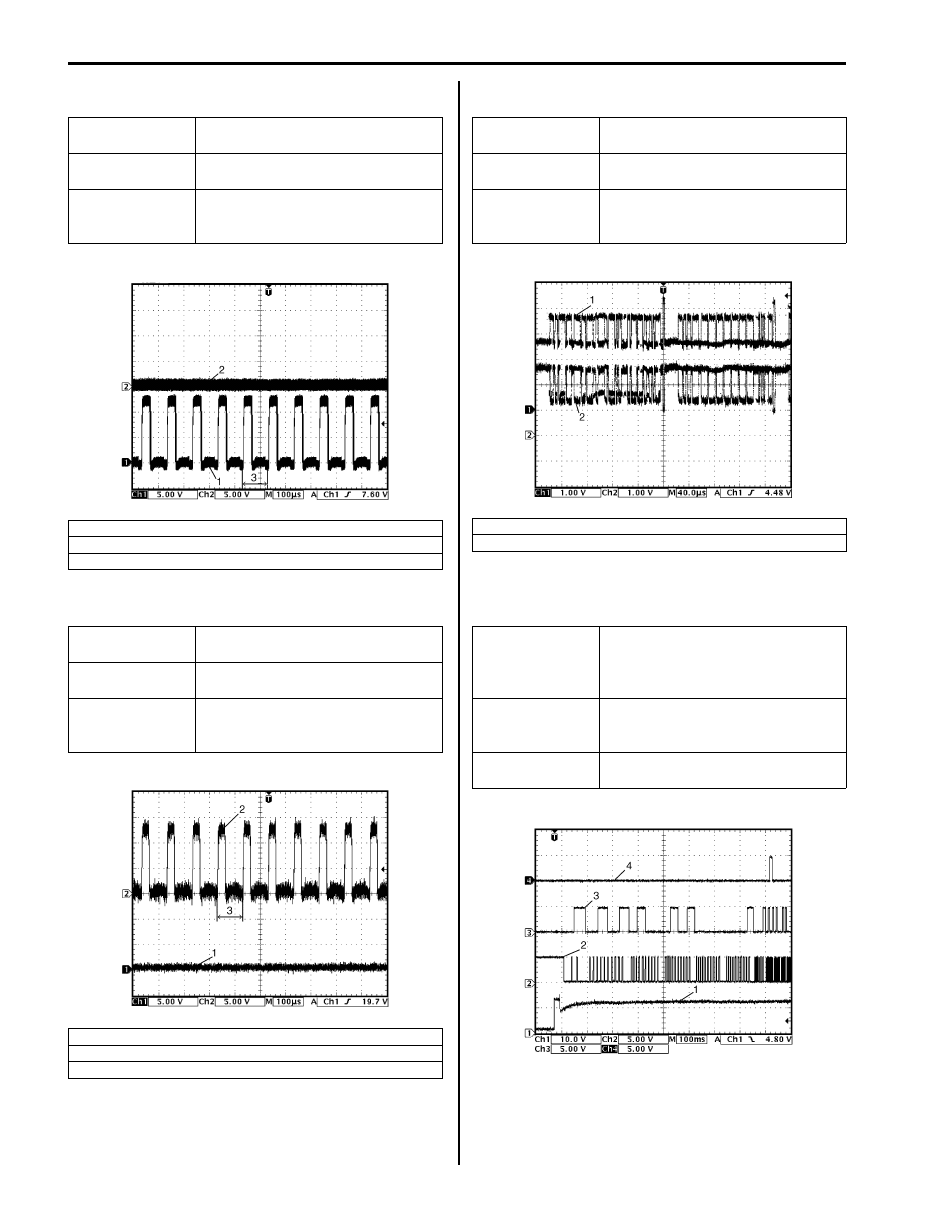

Reference waveform No.25

Throttle actuator output signals:

Reference waveform No.26

Throttle actuator output signals:

Reference waveform No.27

CAN communication line signals:

Reference waveform No.28

Start (1), CKP sensor (2), CMP sensor (3) and ignition

coil No.1 (4) signals:

Measurement

terminal

CH1: E23-4 to C37-81

CH2: E23-5 to C37-81

Oscilloscope

setting

CH1: 5 V/DIV, CH2: 5 V/DIV,

TIME: 100

µs/DIV

Measurement

condition

Ignition switch is at ON position and

accelerator pedal is not depressed

after warmed up engine.

1. Throttle actuator drive signal (E23-4 terminal)

2. Throttle actuator drive signal (E23-5 terminal)

3. One duty cycle

Measurement

terminal

CH1: E23-4 to C37-81

CH2: E23-5 to C37-81

Oscilloscope

setting

CH1: 5 V/DIV, CH2: 5 V/DIV

TIME: 100

µs/DIV

Measurement

condition

Ignition switch is at ON position and

accelerator pedal is at fully

depressed after warmed up engine.

1. Throttle actuator drive signal (E23-4 terminal)

2. Throttle actuator drive signal (E23-5 terminal)

3. One duty cycle

I6JB01110088-01

I6JB01110089-02

Measurement

terminal

CH1: E23-9 to C37-81

CH2: E23-17 to C37-81

Oscilloscope

setting

CH1: 1 V/DIV, CH2: 1V/DIV

TIME: 40

µs/DIV

Measurement

condition

Ignition switch is at ON position.

(Signal pattern is depending on

communication data.)

1. CAN communication line signal (high)

2. CAN communication line signal (low)

Measurement

terminal

CH1: C37-28 to C37-81

CH2: C37-47 to C37-81

CH3: C37-66 to C37-81

CH4: C37-15 to C37-81

Oscilloscope

setting

CH1: 10 V/DIV, CH2: 5 V/DIV,

CH3: 5 V/DIV, CH4: 5 V/DIV

TIME: 100 ms/DIV

Measurement

condition

Engine is at cranking.

I6JB01110090-02

I6JB01110093-02