Suzuki Grand Vitara JB627. Manual - part 41

1A-113 Engine General Information and Diagnosis:

DTC P0300 / P0301 / P0302 / P0303 / P0304 / P0305 / P0306: Misfire Detected

S6JB0B1104037

System Description

ECM measure the angle of the crankshaft based on the pulse signal from the CKP sensor and CMP sensor for each

cylinder. If it detects a large change in the angle speed of the crankshaft, it concludes occurrence of a misfire. When

the number of misfire is counted by ECM beyond the DTC detecting condition, it determine the cylinder where the

misfire occurred and output it as DTC.

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

WARNING

!

• When performing a road test, select a place where there is no traffic or possibility of a traffic

accident and very careful during testing to avoid occurrence of an accident.

• Road test should be carried out with 2 persons, a driver and a tester, on a level road.

NOTE

Check to make sure that the following conditions are satisfied when using this “DTC Confirmation

Procedure”.

• Atmospheric pressure: higher than 75 kpa (560 mmHg) (Altitude: lower than 2790 m (9150 ft)).

• Engine coolant temperature: higher than –10

°C (14 °F).

• Make sure that the ignition timing is good referring to “Ignition Timing Inspection in Section 1H”.

1) With ignition switch OFF, connect scan tool.

2) Turn ON ignition switch and clear DTC by using scan tool if any.

3) Drive vehicle more than 37 mph (60 km/h) for more than 1 minute.

4) Stop vehicle and check DTC and pending DTC by using scan tool.

5

TP sensor check

1) Check TP sensor for performance referring to “Electric

Throttle Body Assembly On-Vehicle Inspection in

Section 1C”.

Is it in good condition?

Substitute a known

good ECM and recheck.

Replace electric throttle

body assembly.

Step

Action

Yes

No

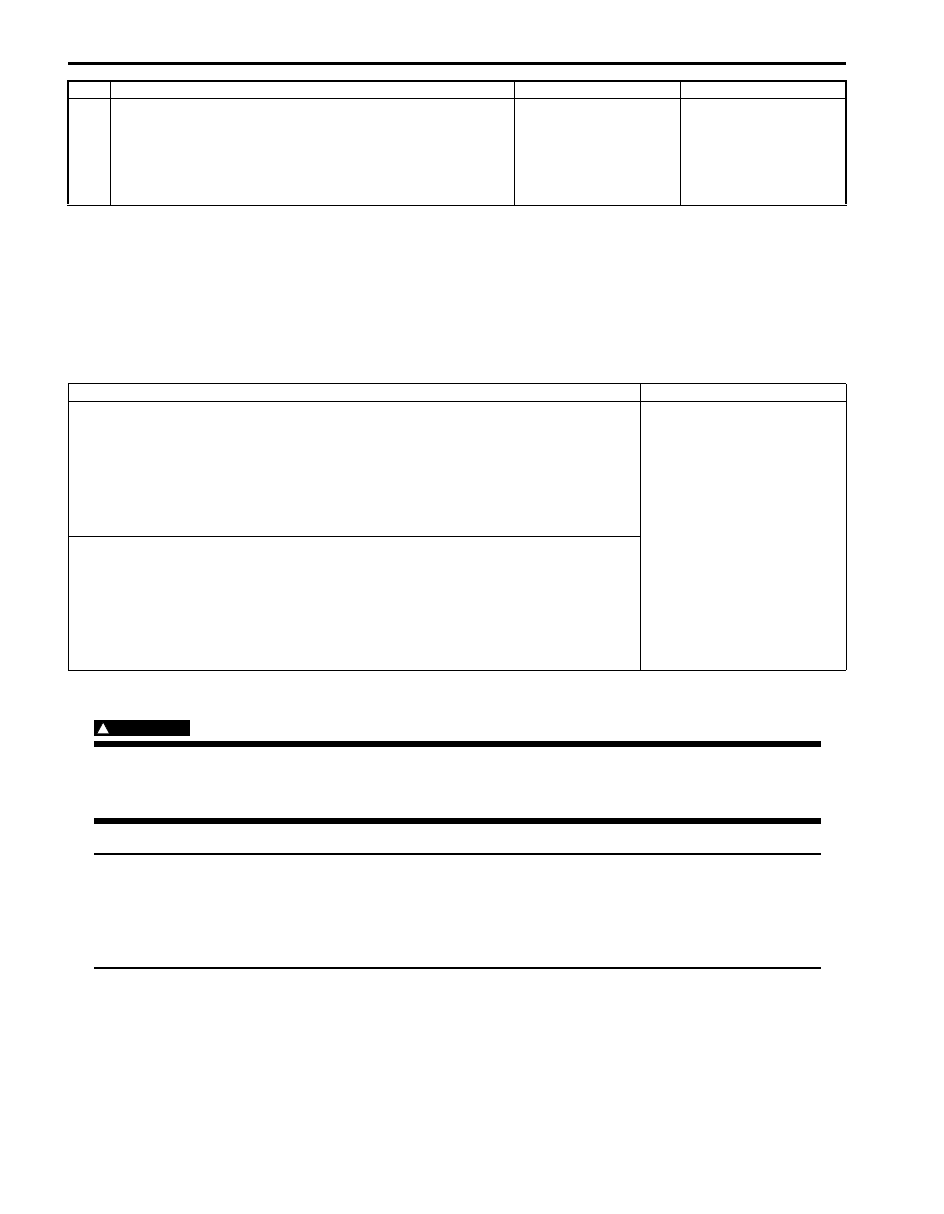

DTC detecting condition

Trouble area

P0300: Random

• Misfire, which causes catalyst to overheat during 200 engine revolutions, is

detected at 2 or more cylinders. (MIL flashes as long as this misfire occurs

continuously.)

• Misfire, which affects exhaust emission adversely during 1000 engine revolutions,

is detected at 2 or more cylinders.

(2 driving cycle detection logic)

• Ignition system

• Fuel injector and its circuit

• Fuel pressure

• EGR system (if equipped)

• Fuel level sensor

• Abnormal air drawn in

• Engine compression

• Valve lash (clearance)

• Valve timing

• Fuel shortage

• Exhaust system

• Fuel of poor quality

P0301: No.1 cylinder, P0302: No.2 cylinder, P0303: No.3 cylinder, P0304: No.4

cylinder, P0305: No.5 cylinder, P0306: No.6 cylinder

• Misfire, which causes catalyst to overheat during 200 engine revolutions, is

detected at 1 cylinder. (MIL flashes as long as this misfire occurs continuously.)

• Misfire, which affects exhaust emission adversely during 1000 engine revolutions,

is detected at 1 cylinder.

(2 driving cycle detection logic)