Suzuki Grand Vitara JB627. Manual - part 39

1A-105 Engine General Information and Diagnosis:

DTC P0171 / P0172: System Too Lean / Too Rich (Sensor-1, Bank-1)

S6JB0B1104034

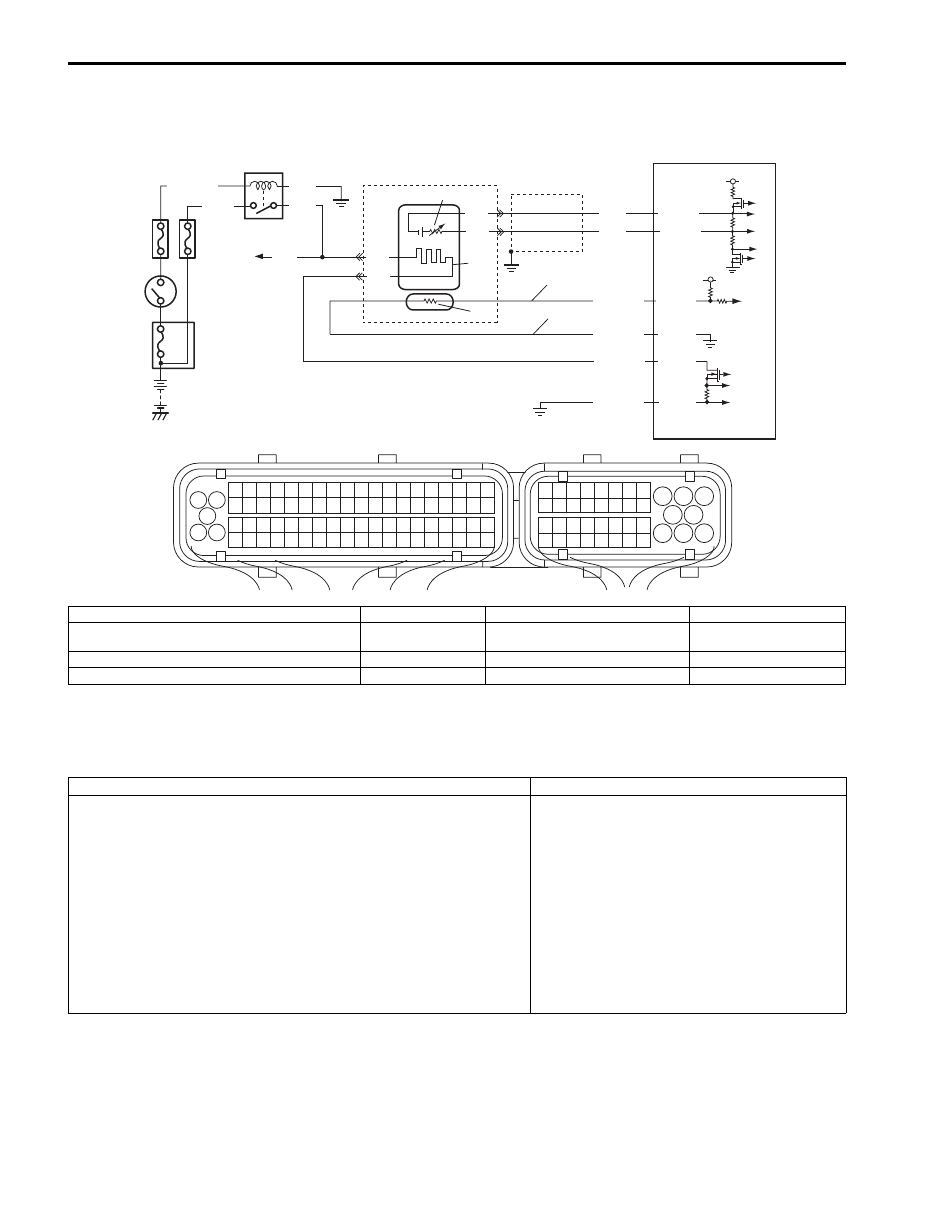

System and Wiring Diagram

A/F Sensor Description

Refer to “A/F Sensor Description”

DTC Detecting Condition and Trouble Area

4

3

9

PNK

6

2

1

a

b

8

5

BLK/WHT

BLK

PNK

GRN

C37-16

C37-77

C37-19

C37-18

BLK

BLK

BLU

WHT

C37-17

C37-79

BLK

WHT

RED/YEL

RED/BLU

PNK/BLK

BLK/YEL

10

7

11

5 V

5 V

1

3 2

4

5

6

7

8

9

1110

12

13

14

15

16

17

18

19

20

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

33

34

35

36

37

38

39

40

32

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

I6JB01110098-01

a. Adjusting resistor (+) circuit of A/F sensor (bank-1)

3. Ignition Switch

7. A/F sensor heater

11. A/F sensor element

b. Adjusting resistor (–) circuit of A/F sensor (bank-1)

4. O2 HTR fuse

8. To A/F sensor (bank-2), HO2S

(bank-1 and -2)

1. HO2S heater relay

5. IG COIL fuse

9. ECM

2. Shield wire

6. A/F sensor

10. Adjusting resistor (if equipped)

DTC detecting condition

Trouble area

DTC P0171 System Too Lean (Sensor-1, Bank-1):

Total fuel trim (short term + long term fuel trim) is larger than 127% for

more than 20 sec, or short term fuel trim is larger than 130% for more

than 30 sec.

(2 driving cycle detection logic)

DTC P0172 System Too Rich (Sensor-1, Bank-1):

Total fuel trim (short term + long term fuel trim) is smaller than 71%

for more than 20 sec, or short term fuel trim is larger than 70% for

more than 30 sec.

(2 driving cycle detection logic)

• Vacuum leakage

• Exhaust gas leakage

• Fuel pressure out of specification

• Fuel injector malfunction

• A/F sensor malfunction

• MAF sensor malfunction

• Intake & exhaust valve clearance

• Intake & exhaust valve

• Valve timing

• ECM