Suzuki Grand Vitara JB627. Manual - part 4

00-13 Precautions:

Brakes Caution and Note

S6JB0B0000014

CAUTION

!

All brake fasteners are important attaching

parts in that they could affect the

performance of vital parts and systems, and/

or could result in major repair expense. They

must be replaced with one of same part

number or with an equivalent part if

replacement becomes necessary. Do not use

a replacement part of lesser quality or

substitute design. Torque values must be

used as specified during reassembly to

assure proper retention of all parts. There is

to be no welding as it may result in extensive

damage and weakening of the metal.

NOTE

Before inspecting and servicing brakes for

vehicle equipped with ABS, make sure that

ABS is in good condition.

Differential Gear Oil Note

S6JB0B0000015

NOTE

• When having driven through water, check

immediately if water has entered (if so, oil

is cloudy). Water mixed oil must be

changed at once.

• Whenever vehicle is hoisted for any other

service work than oil change, also be sure

to check for oil leakage and status of

breather hoses.

Repair Instructions

Electrical Circuit Inspection Procedure

S6JB0B0006001

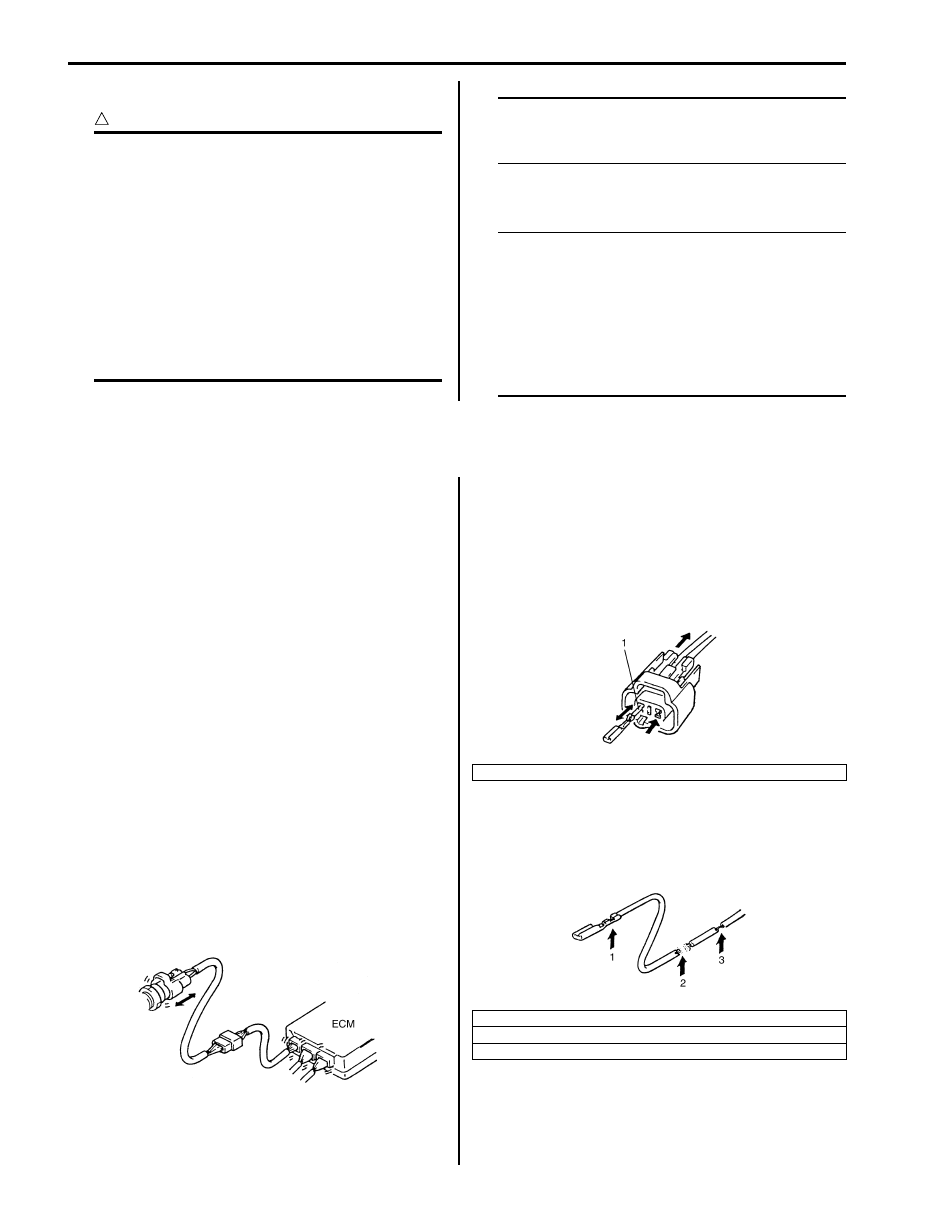

While there are various electrical circuit inspection

methods, described here is a general method to check

its open and short circuit by using an ohmmeter and a

voltmeter.

Open Circuit Check

Possible causes for the open circuit are as follows. As

the cause is in the connector or terminal in many cases,

they need to be checked particularly carefully.

• Loose connection of connector

• Poor contact of terminal (due to dirt, corrosion or rust

on it, poor contact tension, entry of foreign object etc.)

• Wire harness being open

When checking system circuits including an electronic

control unit such as ECM, TCM, ABS control module,

etc., it is important to perform careful check, starting with

items which are easier to check.

1) Disconnect negative cable from battery

2) Check each connector at both ends of the circuit

being checked for loose connection. Also check lock

condition of connector if equipped with connector

lock.

3) Using a test male terminal, check both terminals of

the circuit being checked for contact tension of its

female terminal. Check each terminal visually for

poor contact (possibly caused by dirt, corrosion, rust

entry of foreign object, etc.). At the same time, check

to make sure that each terminal is locked in the

connector fully.

4) Using continuity check or voltage check the following

procedure, check the wire harness for open circuit

and poor connection with its terminals. Locate

abnormality, if any.

I2RH01010049-01

1. Check contact tension by inserting and removing just for once.

1. Looseness of crimping

2. Open

3. Thin wire (single strand of wire)

I2RH01010050-01

I2RH01010051-01