Subaru Legacy IV (2008 year). Manual - part 984

AC-39

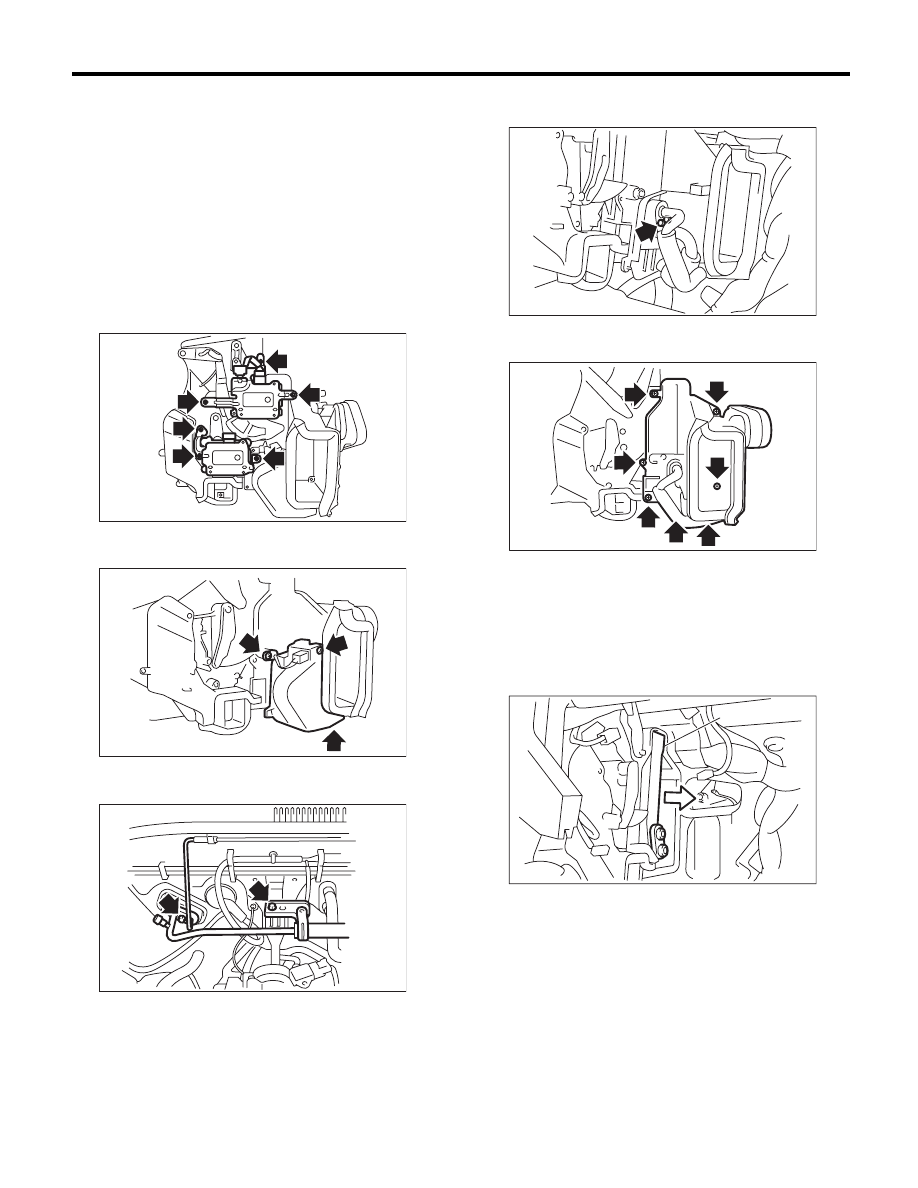

Evaporator

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

18.Evaporator

A: REMOVAL

1) Using the refrigerant recovery system, drain the

refrigerant. <Ref. to AC-22, PROCEDURE, Refrig-

erant Recovery Procedure.>

2) Disconnect the ground cable from the battery.

3) Remove the blower motor unit assembly. <Ref.

to AC-28, REMOVAL, Blower Motor Unit Assem-

bly.>

4) Disconnect the connector, remove the screw

and then remove the air-mix door actuator and

mode door actuator.

5) Disconnect the connector, remove the pipe cov-

er and evaporator sensor.

6) Remove the bolts securing expansion valve and

pipe in engine compartment.

7) Remove the bolt which holds the pipe to the

evaporator.

8) Remove the screws and clip to remove the evap-

orator cover.

9) Pull out the evaporator (A) in the direction of the

arrow.

CAUTION:

If the evaporator is replaced, add an appropri-

ate amount of compressor oil to evaporator.

<Ref. to AC-27, REPLACEMENT, Compressor

Oil.>

B: INSTALLATION

Install in the reverse order of removal.

AC-00923

AC-00924

AC-00925

AC-00926

AC-01187

AC-00928

(A)