Subaru Legacy IV (2008 year). Manual - part 971

PS-46

Oil Pump

POWER ASSISTED SYSTEM (POWER STEERING)

B: INSTALLATION

1. H4 MODEL

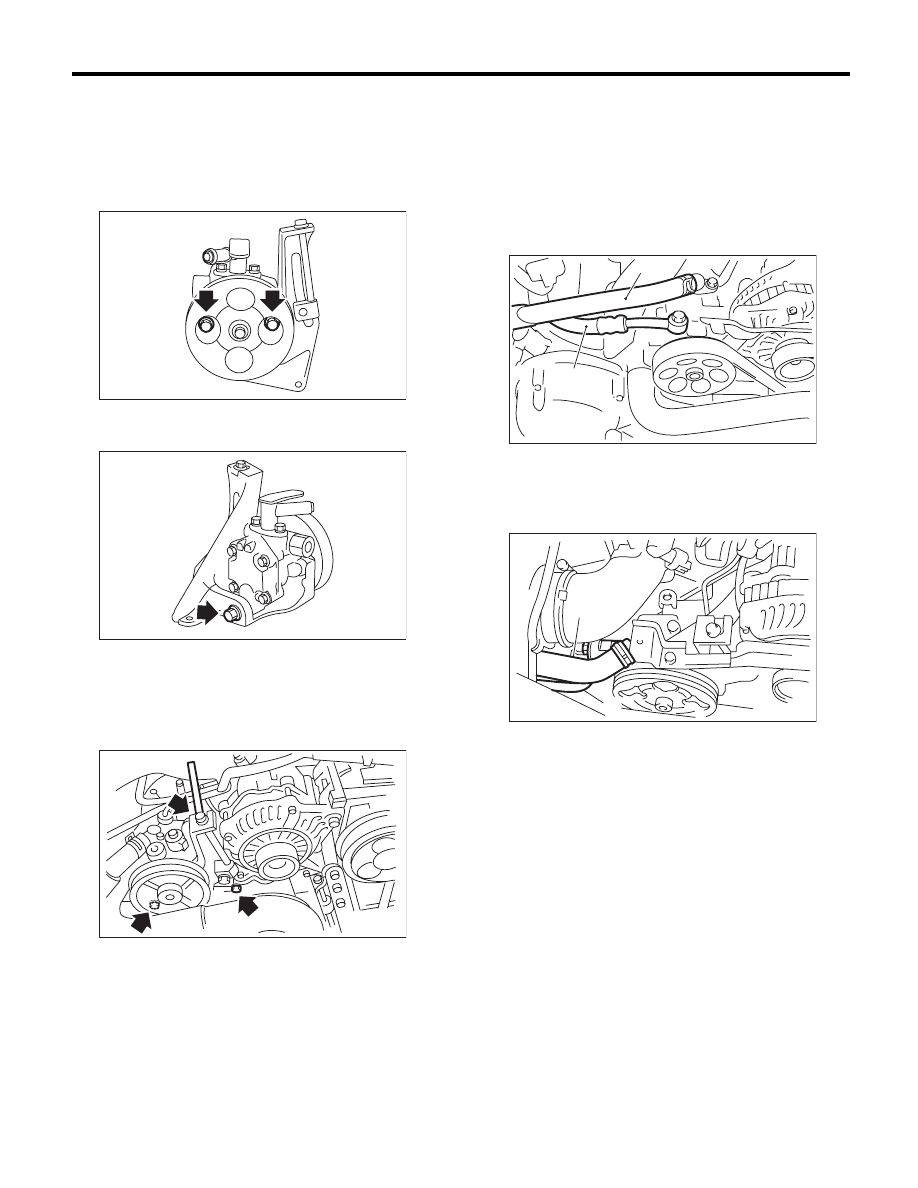

1) Install the oil pump to the bracket.

Tightening torque:

15.7 N·m (1.6 kgf-m, 11.6 ft-lb)

Tightening torque:

48.4 N·m (4.9 kgf-m, 35.7 ft-lb)

2) Attach the installation bolts of the power steering

pump bracket.

Tightening torque:

<Ref. to PS-6, OIL PUMP, COMPONENT, Gen-

eral Description.>

3) After installing the oil pump, fill the fluid while ro-

tating the pulley by hand to bleed air from the oil

pump.

CAUTION:

Always fill the oil pump with the fluid to prevent

abnormal noise and seizure of the oil pump.

4) Connect the pressure hose and suction hose.

Tightening torque:

Eye bolt

40 N·m (4.1 kgf-m, 29.5 ft-lb)

CAUTION:

Be careful not to twist hoses. Twisted hoses

may contact other parts.

• Non-turbo model

• Turbo model

5) Connect the power steering pressure switch

connector.

6) Install the V-belts to the oil pump.

7) Check the tension of the V-belt.

<Ref. to ME(H4SO)-40, INSPECTION, V-belt.>

8) Tighten the lock bolt of the belt tension nut.

Tightening torque:

25 N·m (2.5 kgf-m, 18.4 ft-lb)

9) Install the pulley belt cover.

10) Install the air intake duct.

<Ref. to IN(H4DOTC)-9, INSTALLATION, Air In-

take Duct.> <Ref. to IN(H4SO)-8, INSTALLATION,

Air Intake Duct.>

11) Connect the ground cable to battery.

PS-00128

PS-00137

PS-00188

(1) Suction hose

(2) Pressure hose

(1) Suction hose

(2) Pressure hose

PS-00688

(1)

(2)

(2)

PS-00459

(1)