Subaru Legacy IV (2008 year). Manual - part 966

PS-26

Steering Gearbox

POWER ASSISTED SYSTEM (POWER STEERING)

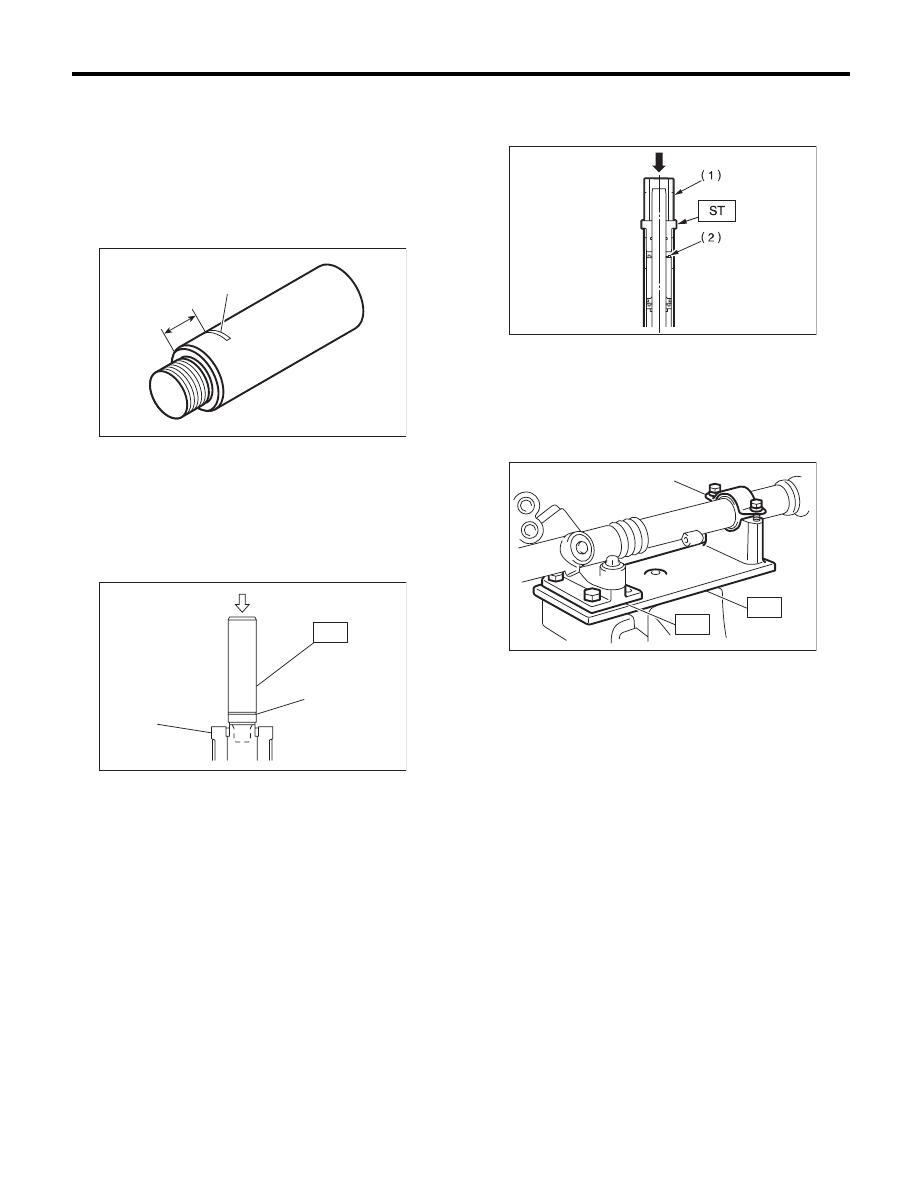

11) Put a mark at the specified position measured

from the end surface of ST, as shown in the figure.

Specified position:

Except for 2.5 GT-B and 3.0 R-LTD:

13.5 mm (0.53 in)

2.5 GT-B and 3.0 R-LTD:

18.9 mm (0.74 in)

ST

34199FE000

INSTALLER & REMOVER

12) Set the ST to the end of rack.

ST

34199FE000

INSTALLER & REMOVER

13) Using a press, press-fit until the mark on ST is

aligned to the end surface of holder.

14) Remove the ST and holder.

15) Insert the outer side oil seal into the rack using

the same procedure as steps 5) and 6).

ST

926390001

COVER & REMOVER

16) Make the ST and the pipe through the rack, and

then press-fit the outer side oil seal using a press.

ST

34199AG010 INSTALLER

17) Secure the gearbox in a vise using ST.

ST1

926200000

STAND

ST2

34199AG000 BOSS D

18) Tighten a new holder.

Tightening torque:

70 N·m (7.1 kgf-m, 51.6 ft-lb)

(1) 13.5 mm (0.53 in) or 18.9 mm (0.74 in)

(2) Put a mark.

(1) Mark

(2) Holder

PS-00851

(1)

(2)

PS-00522

ST

(1)

(2)

(1) Pipe

(2) Outer side oil seal

(1) Clamp

PS-00852

PS-00492

(1)

ST1

ST2