Subaru Legacy IV (2008 year). Manual - part 828

6MT-125

Clutch Housing

MANUAL TRANSMISSION AND DIFFERENTIAL

D: ASSEMBLY

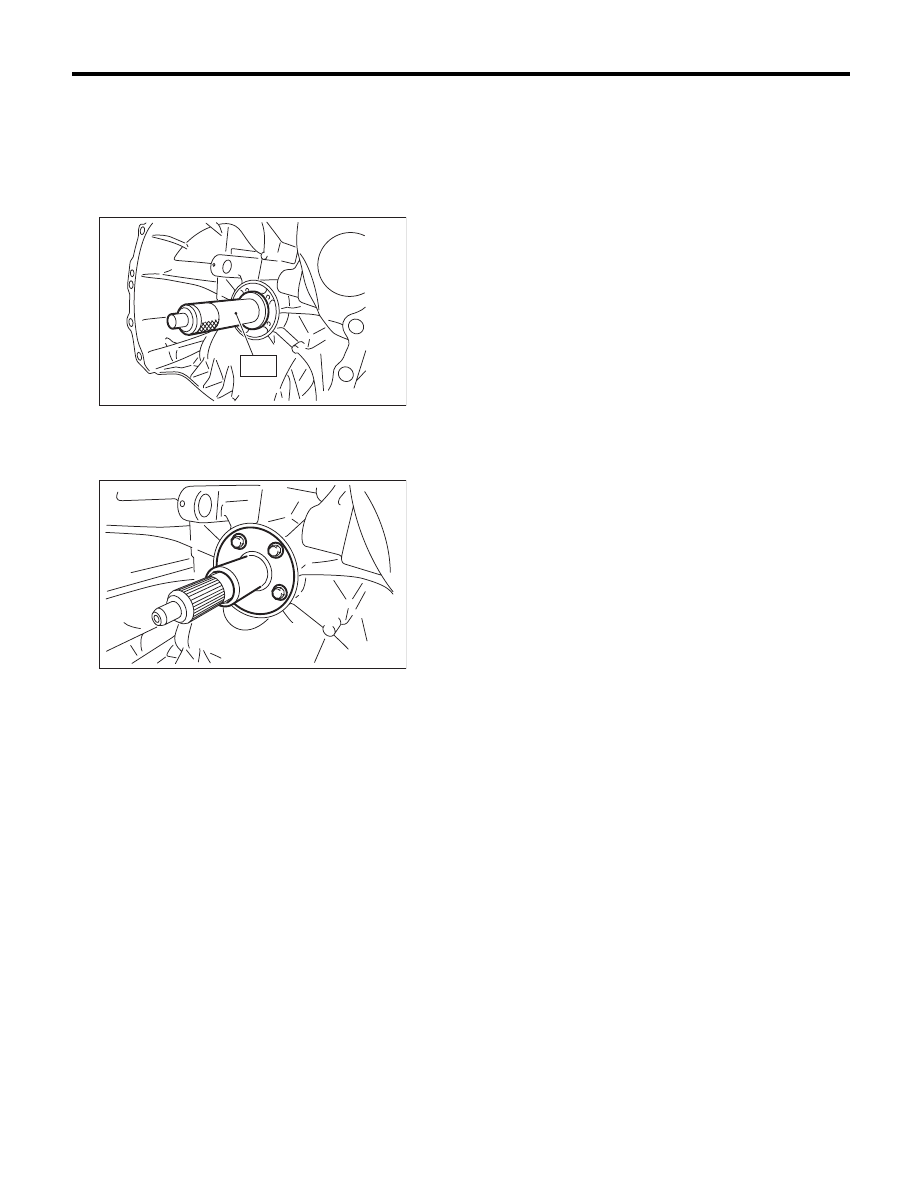

1) Attach the oil seal to the clutch housing, being

careful not to damage the seal.

NOTE:

Use a new oil seal.

ST

18657AA020

OIL SEAL INSTALLER

2) Install the clutch release bearing guide.

Tightening torque:

6.4 N·m (0.7 kgf-m, 4.7 ft-lb)

E: INSPECTION

1) Check to make sure there is no damage or

cracks on the clutch housing. If there is excessive

damage, replace the clutch housing.

2) Inspect the clutch housing for transmission gear

oil leakage. If any oil leaks are found, repair or re-

place the applicable part.

MT-01382

ST

MT-01383