Subaru Legacy IV (2008 year). Manual - part 821

6MT-97

Drive Pinion Shaft Assembly

MANUAL TRANSMISSION AND DIFFERENTIAL

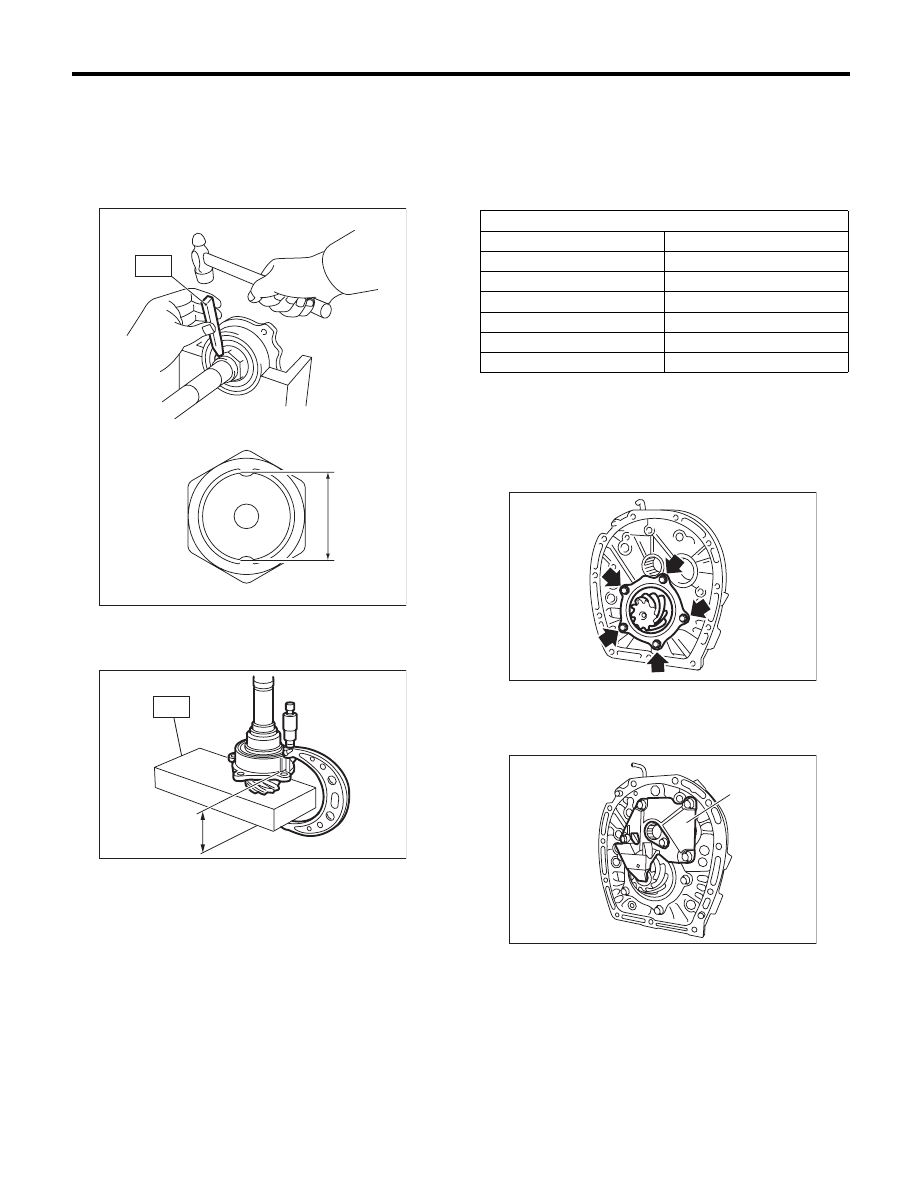

7) Using the ST, crimp the lock nut in 2 locations,

with dimensions within A 37

r0.5 mm (1.46r0.02

in).

ST

18670AA000

PUNCH

NOTE:

Do not damage the crimp area of the lock nut.

8) Using the ST, measure drive pinion measure-

ment B.

ST

398643600

GAUGE

9) Calculate from the calculation below to select 1

or 2 drive pinion shims from the following table.

6.5

r0.0625 mm – (B – A) [0.26r0.0025 in – (B – A)]

NOTE:

A: Measurement value in step 1)

B: Measurement value in step 8)

10) Apply transmission gear oil to the side face of

the taper roller bearing, and attach the drive pinion

shaft and the selected shims to the adapter plate.

Tightening torque:

54 N·m (5.5 kgf-m, 40 ft-lb)

11) Install the oil guide A.

Tightening torque:

18 N·m (1.8 kgf-m, 13.3 ft-lb)

MT-00649

A

ST

MT-00650

B

ST

Drive pinion shim

Part No.

Thickness mm (in)

32295AA270

0.15 (0.0059)

32295AA280

0.175 (0.0069)

32295AA290

0.20 (0.0079)

32295AA300

0.225 (0.0089)

32295AA310

0.25 (0.0098)

32295AA320

0.275 (0.0108)

(A) Oil guide A

MT-00642

MT-01624

(A)