Subaru Legacy IV (2008 year). Manual - part 819

6MT-89

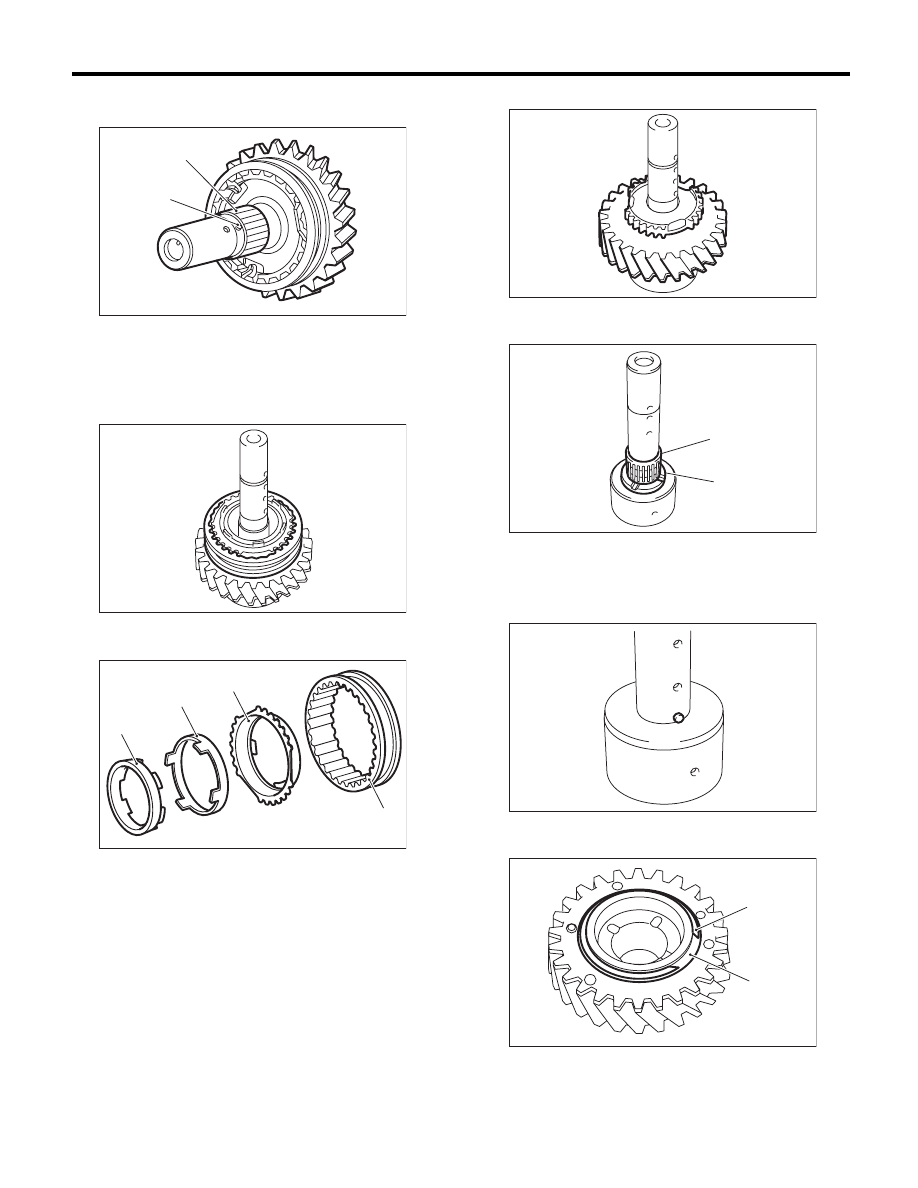

Reverse Idler Gear Assembly

MANUAL TRANSMISSION AND DIFFERENTIAL

4) Remove the knock pin and reverse idler gear

needle bearing.

5) Remove the collar.

6) Remove the reverse sleeve.

7) Remove the outer baulk ring, reverse synchro

cone and inner baulk ring from the reverse sleeve.

8) Remove reverse idler gear No. 2.

9) Remove the counter high & low washer and nee-

dle bearing.

10) Remove the knock pin.

11) Remove the snap ring and friction plate from

reverse gear.

(A) Knock pin

(B) Reverse idler gear needle bearing

(A) Reverse sleeve

(B) Outer baulk ring

(C) Reverse synchro cone

(D) Inner baulk ring

MT-00620

(A)

(B)

MT-00622

MT-01507

(A)

(B)

(C)

(D)

(A) Needle bearing

(B) Counter high and low washer

(A) Snap ring

(B) Friction plate

MT-00624

MT-00625

(A)

(B)

MT-00626

MT-00627

(B)

(A)