Subaru Legacy IV (2008 year). Manual - part 809

6MT-49

Extension Case

MANUAL TRANSMISSION AND DIFFERENTIAL

2. TRANSFER DRIVE GEAR THRUST

WASHER SELECTION

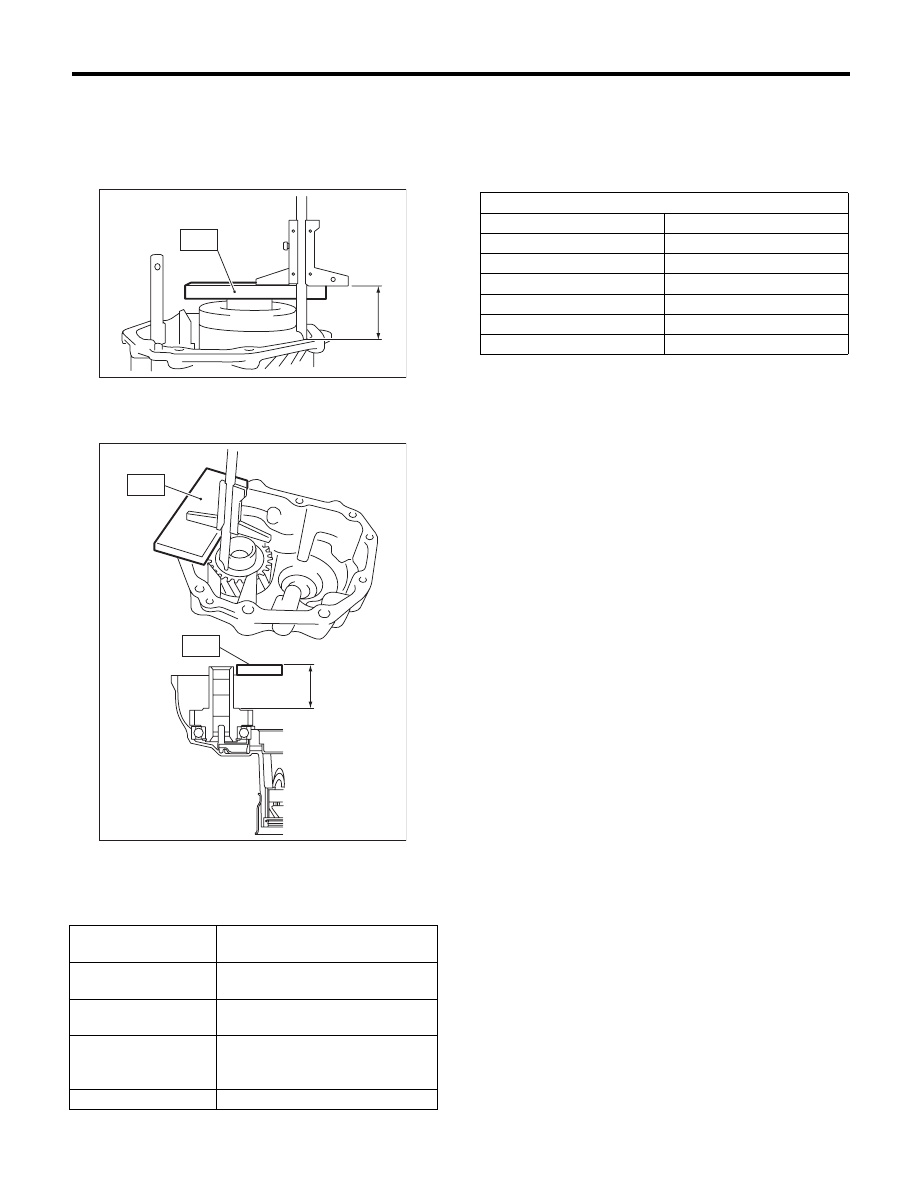

1) Measure height “Z” between the transmission

case end area and ST.

ST

398643600

GAUGE

2) Measure depth “Y” between the end of the ST

and the transfer drive gear.

ST

398643600

GAUGE

3) Using the following calculation, calculate the

transfer drive gear thrust washer value “t”.

t = {Y – 15 mm (0.59 in)} – {Z – 15 mm (0.59 in)} –

0.45 — 0.65 mm (0.018 — 0.026 in)

4) Refer to the calculated value “t” to select the

closest thrust washer from the following table.

Standard clearance between the thrust washer

and transfer drive gear

0.45 — 0.65 mm (0.018 — 0.026 in)

5) Install the selected thrust washer.

t

mm (in)

Transfer drive gear thrust washer

thickness

Y

mm (in)

Depth between the end of the ST

and the transfer drive gear

Z

mm (in)

Height from the end of the trans-

mission case to the end of the ST.

0.45 — 0.65 mm

(0.018 — 0.026 in)

Standard clearance between the

thrust washer and transfer drive

gear

15 mm (0.591 in)

Thickness of ST

MT-00492

Z

ST

MT-00493

Y

ST

ST

Thrust washer (36.3 × 52 × t)

Part number

Thickness mm (in)

803036070

0.80 (0.0315)

803036071

0.95 (0.0374)

803036072

1.10 (0.0433)

803036073

1.25 (0.0492)

803036074

1.40 (0.0551)

803036075

0.65 (0.0256)