Subaru Legacy IV (2008 year). Manual - part 808

6MT-45

Extension Case

MANUAL TRANSMISSION AND DIFFERENTIAL

D: ASSEMBLY

1) Install the reverse check system. <Ref. to 6MT-

51, INSTALLATION, Reverse Check System.>

2) Install the extension case oil seal. <Ref. to 6MT-

28, REPLACEMENT, Oil Seal.>

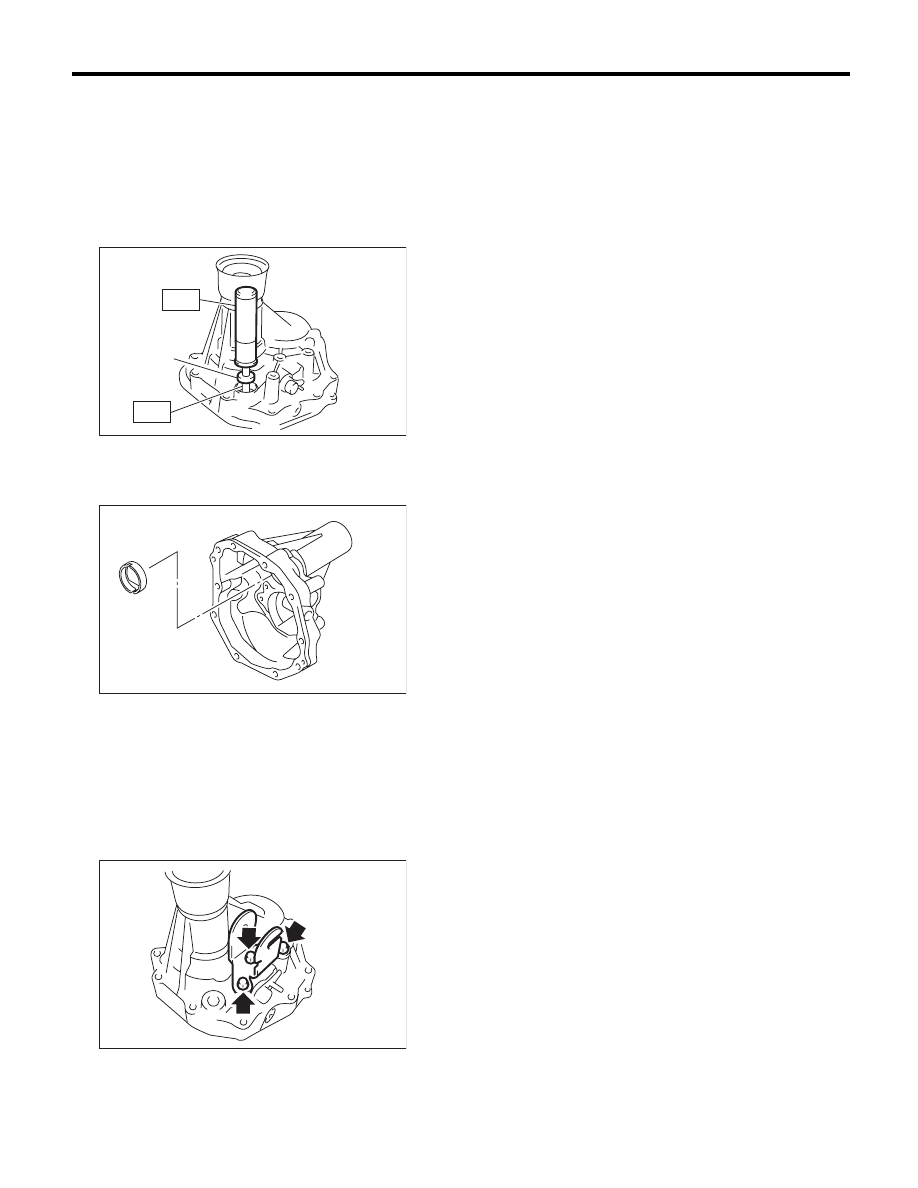

3) Install a shifter arm oil seal using the ST.

ST1

18657AA000

INSTALLER

ST2

18671AA000

OIL SEAL GUIDE

4) Install the oil plate.

5) Select the thrust washer of the bearing, and at-

tach to the extension case. <Ref. to 6MT-46, AD-

JUSTMENT, Extension Case.>

6) Apply a thin coat of oil to the outer surface of the

bearing cone, and attach to the extension case.

7) Install the shift bracket.

Tightening torque:

25 N·m (2.5 kgf-m, 18.4 ft-lb)

8) Attach the oil guide and the transfer driven gear.

<Ref. to 6MT-53, INSTALLATION, Transfer Drive

Gear.>

E: INSPECTION

1) Check to make sure there is no damage or

cracks on the extension case. If damage or crack-

ing is found, replace the extension case.

2) Inspect for oil leaks at the extension case and

transmission case oil seals and mating surfaces. If

there are oil leaks, replace the oil seal and liquid

gasket.

(A) Oil seal

MT-00482

(A)

ST1

ST2

MT-00483

MT-00478