Subaru Legacy IV (2008 year). Manual - part 712

4AT(diag)-69

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

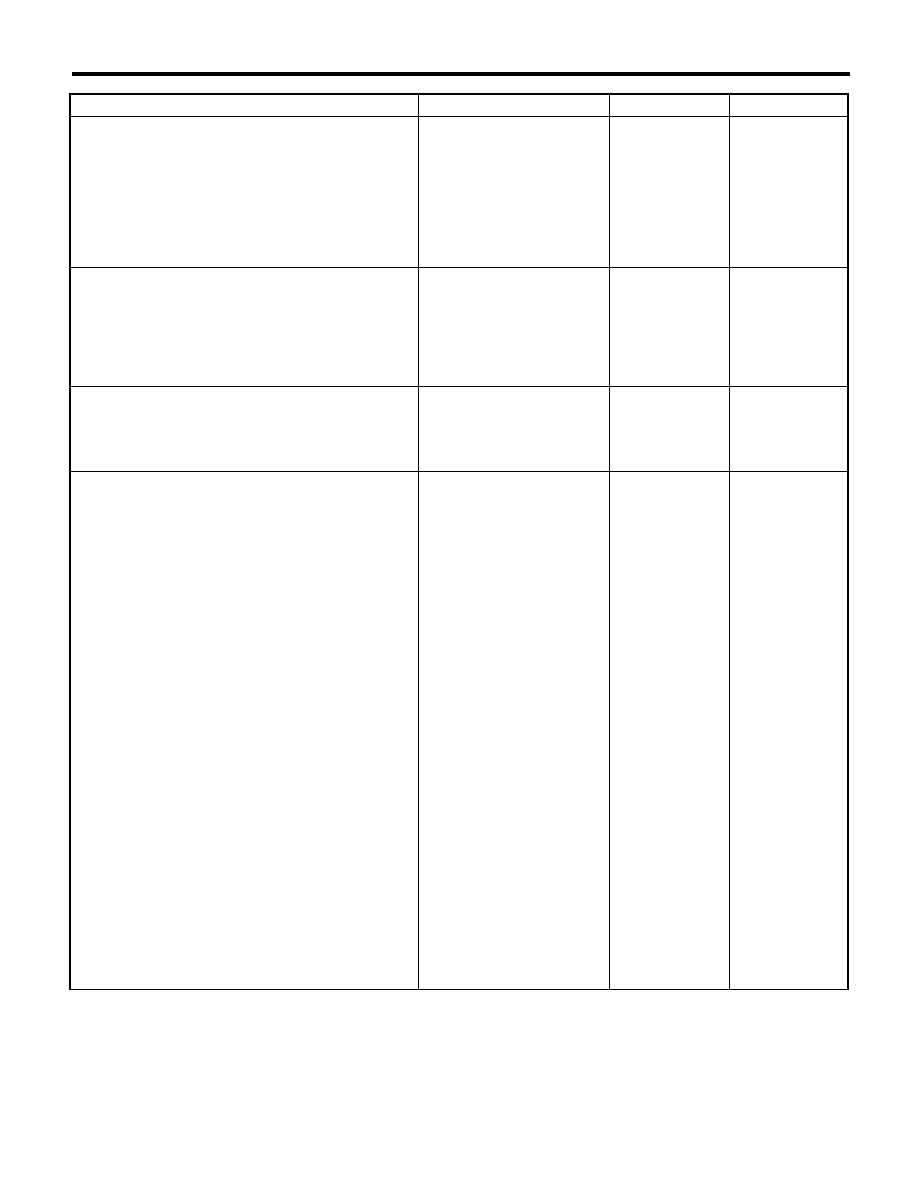

Step

Check

Yes

No

1

CHECK HARNESS CONNECTOR BETWEEN

TCM AND TRANSMISSION.

1) Turn the ignition switch to OFF.

2) Disconnect the connectors from TCM and

transmission.

3) Measure the resistance of harness between

TCM connector and transmission connector.

Connector & terminal

(B55) No. 6 — (B11) No. 7:

Is the resistance less than 1

:? Go to step 2.

Repair the open

circuit of harness

between TCM and

transmission con-

nector.

2

CHECK HARNESS CONNECTOR BETWEEN

TCM AND TRANSMISSION.

Measure the resistance of the harness connec-

tor between TCM connector and chassis

ground.

Connector & terminal

(B55) No. 6 — Chassis ground:

Is the resistance 1 M

: or

more?

Go to step 3.

Repair the short

circuit of harness

between TCM and

transmission con-

nector.

3

CHECK HIGH CLUTCH DUTY SOLENOID.

Measure the resistance between transmission

connector receptacle’s terminals.

Connector & terminal

(T4) No. 7 — No. 20:

Is the resistance 2.0 — 6.0

:? Go to step 4.

Go to step 7.

4

CHECK OUTPUT SIGNAL FROM TCM US-

ING SUBARU SELECT MONITOR.

1) Connect the connectors to TCM and trans-

mission.

2) Lift up the vehicle.

3) Connect the Subaru Select Monitor to data

link connector.

4) Start the engine, and run the Subaru Select

Monitor.

5) Start the engine and warm up the engine

until the ATF temperature exceeds 80°C

(176°F).

NOTE:

If the ambient temperature is below 0°C (32°F),

drive the vehicle until the ATF reaches its oper-

ating temperature.

6) Read the data of “High Clutch Duty” using

Subaru Select Monitor.

• High clutch duty solenoid is indicated in “%”.

7) Shift the select lever to “D”, and slowly

increase vehicle speed to measure at 3rd or

4th.

NOTE:

The speed difference between front and rear

wheels may illuminate the ABS warning light,

but this does not indicate a malfunction. When

AT control diagnosis is finished, perform the

ABS or VDC clear memory of on-board diag-

nostics system. <Ref. to ABS(diag)-20, Clear

Memory Mode.> <Ref. to VDC(diag)-23, Clear

Memory Mode.>

Is the measured value 0%?

Go to step 5.

Go to step 6.