Subaru Legacy IV (2008 year). Manual - part 570

EN(H6DO)(diag)-253

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

8

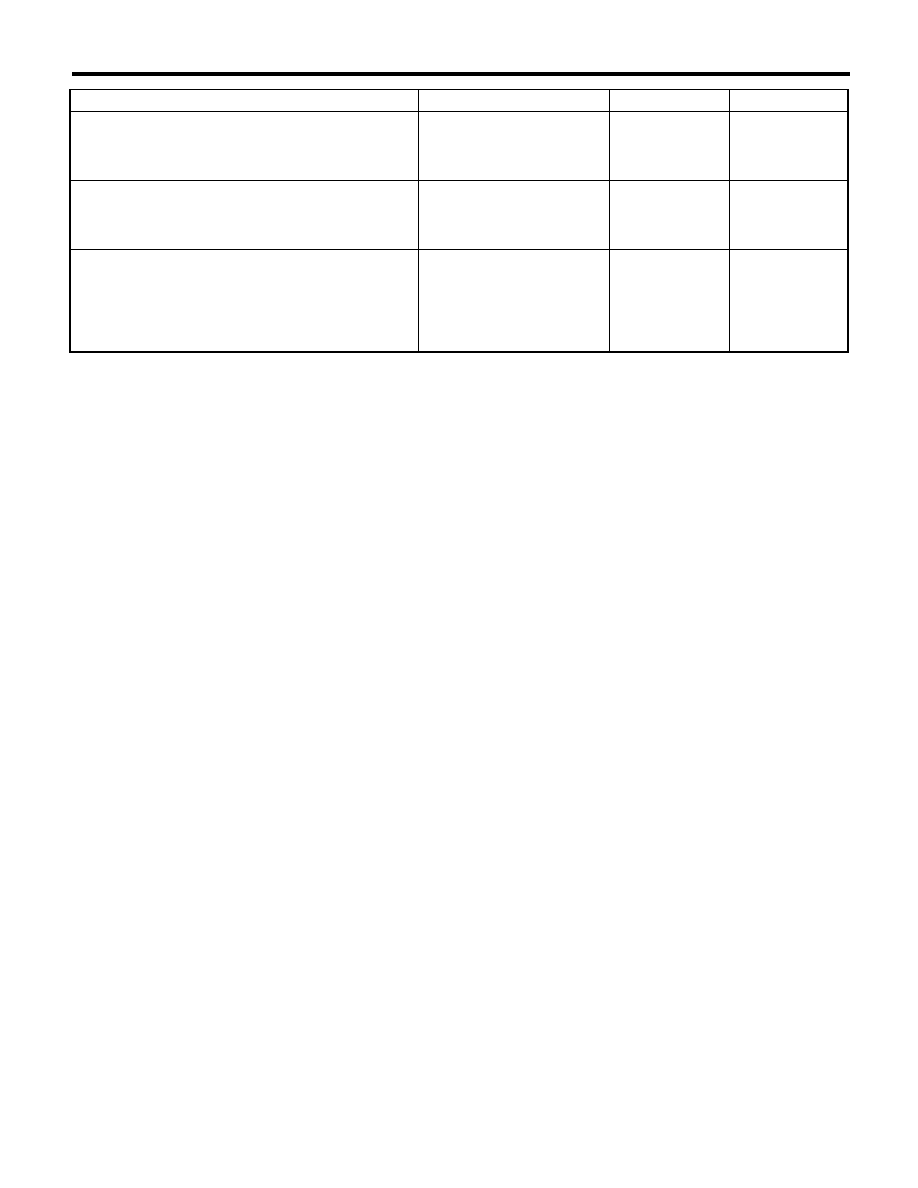

CHECK CANISTER.

Is the canister damaged or is

there a hole of more than

0.5 mm (0.020 in) dia. in it?

Repair or replace

the canister. <Ref.

to EC(H6DO)-6,

Canister.>

Go to step 9.

9

CHECK FUEL TANK.

Remove the fuel tank. <Ref. to FU(H6DO)-45,

Fuel Tank.>

Is the fuel tank damaged or is

there any hole of more than

0.5 mm (0.020 in) dia. in it?

Repair or replace

the fuel tank. <Ref.

to FU(H6DO)-45,

Fuel Tank.>

Go to step 10.

10

CHECK ANY OTHER MECHANICAL TROU-

BLE IN EVAPORATIVE EMISSION CON-

TROL SYSTEM.

Is there any hole of more than

0.5 mm (0.020 in) dia., crack,

clogging, or disconnections,

bend, misconnection of hoses

or pipes in evaporative emis-

sion control system?

Repair or replace

the hoses or pipes.

Repair the poor

contact of ECM

connector.

Step

Check

Yes

No