Subaru Legacy IV (2008 year). Manual - part 563

EN(H6DO)(diag)-225

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

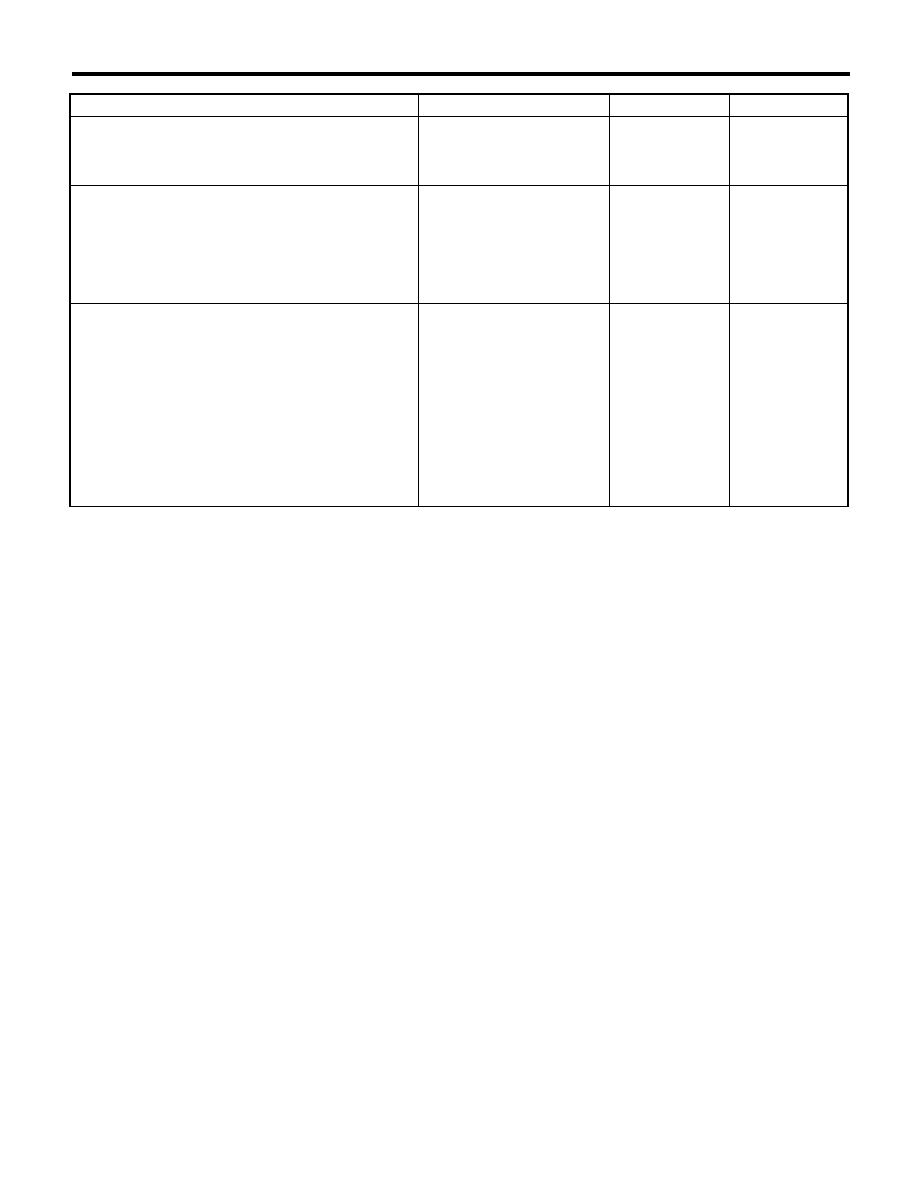

Step

Check

Yes

No

1

CHECK CONDITION OF CRANKSHAFT PO-

SITION SENSOR.

Is the crankshaft position sen-

sor installation bolt tightened

securely?

Go to step 2.

Tighten the crank-

shaft position sen-

sor installation bolt

securely.

2

CHECK CRANKSHAFT POSITION SENSOR.

1) Turn the ignition switch to OFF.

2) Remove the crankshaft position sensor.

3) Measure the resistance between connector

terminals of crankshaft position sensor.

Terminals

No. 1 — No. 2:

Is the resistance between 1 and

4 k

:?

Go to step 3.

Replace the crank-

shaft position sen-

sor. <Ref. to

FU(H6DO)-21,

Crankshaft Posi-

tion Sensor.>

3

CHECK HARNESS BETWEEN ECM AND

CRANK SHAFT POSITION SENSOR.

1) Disconnect the connectors from ECM.

2) Measure the resistance of harness between

ECM and crankshaft position sensor connector.

Connector & terminal

(B134) No. 13 — (E10) No. 1:

(B134) No. 14 — (E10) No. 2:

Is the resistance less than 1

:? Repair the poor

contact of ECM

and crankshaft

position sensor

connector.

Repair the harness

and connector.

NOTE:

In this case, repair

the following item:

• Open circuit in

harness between

ECM and crank-

shaft position sen-

sor connector

• Poor contact of

coupling connector