Subaru Legacy IV (2008 year). Manual - part 561

EN(H6DO)(diag)-217

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

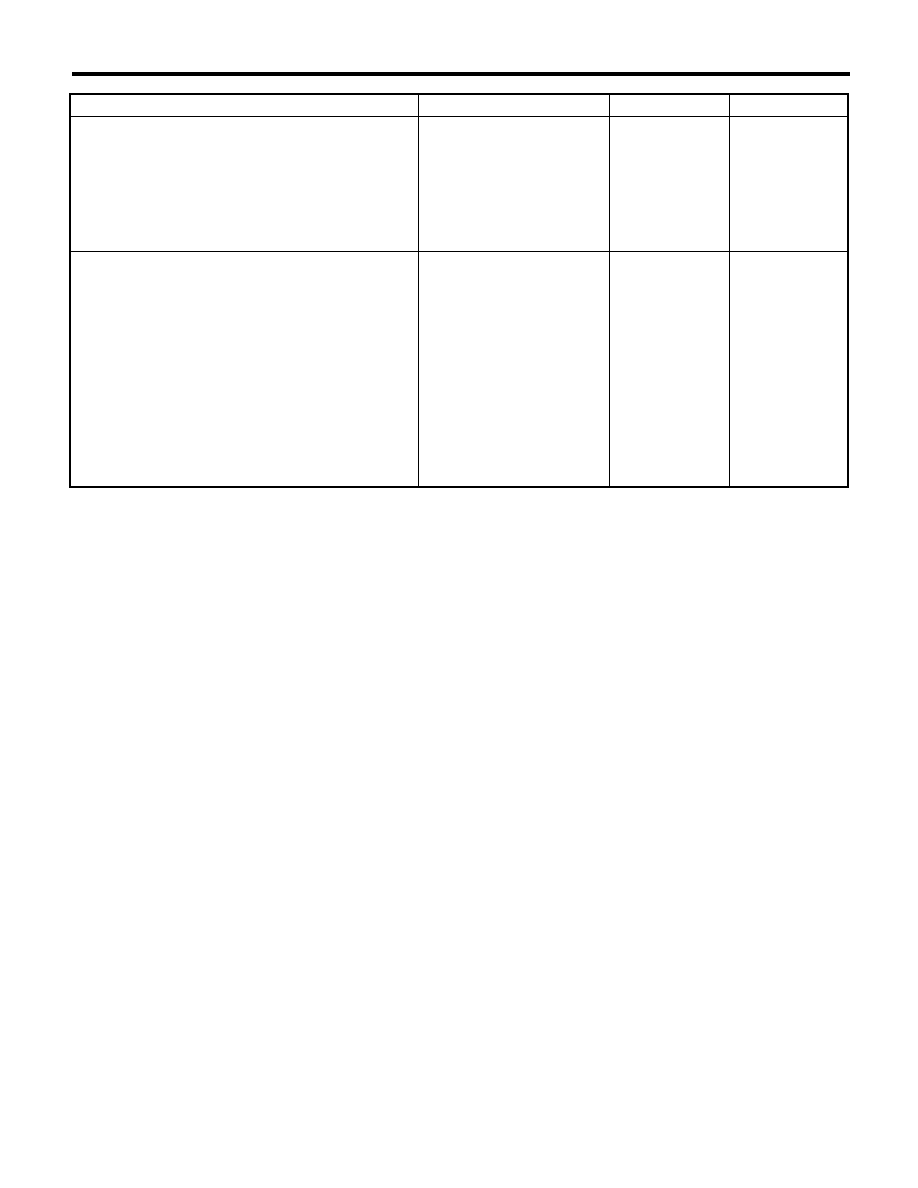

Step

Check

Yes

No

1

CHECK HARNESS BETWEEN ECM AND

KNOCK SENSOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connectors from ECM.

3) Measure the resistance between ECM con-

nectors.

Connector & terminal

(B134) No. 15 — (B134) No. 29:

Is the resistance 600 k

: or

more?

Go to step 2.

Repair the poor

contact of ECM

connector.

2

CHECK KNOCK SENSOR.

1) Disconnect the connector from knock sen-

sor.

2) Measure the resistance between knock

sensor terminals.

Terminals

No. 1 — No. 2:

Is the resistance 600 k

: or

more?

Replace the knock

sensor. <Ref. to

FU(H6DO)-23,

Knock Sensor.>

Repair the harness

and connector.

NOTE:

In this case, repair

the following item:

• Open circuit of

harness between

ECM and knock

sensor

• Poor contact of

the knock sensor

connector

• Poor contact of

coupling connector