Subaru Legacy IV (2008 year). Manual - part 386

EN(H4DOTC)(diag)-365

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

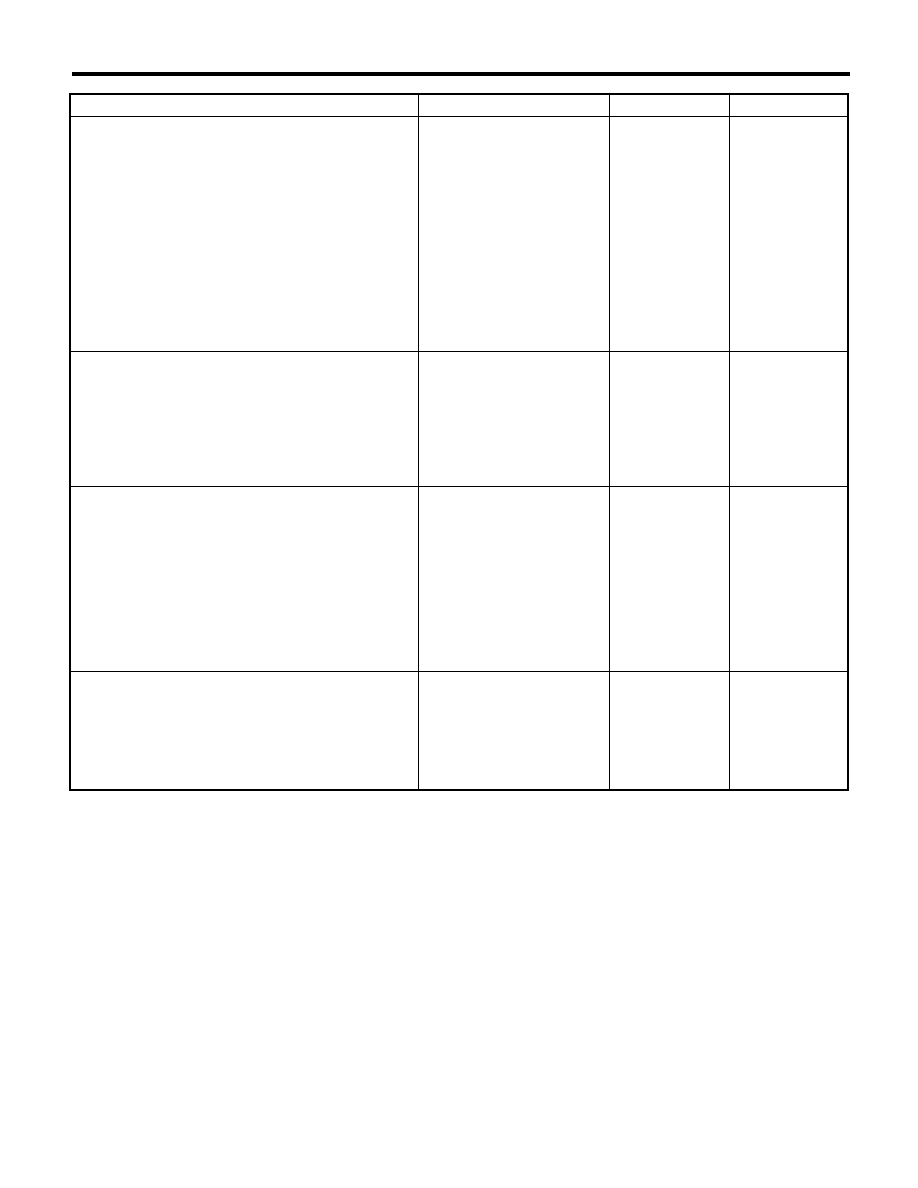

Step

Check

Yes

No

1

CHECK SECONDARY AIR PIPING PRES-

SURE.

1) Turn the ignition switch to ON.

2) Using the Subaru Select Monitor, read sec-

ondary air piping pressure data, and compare

with the actual atmospheric pressure.

NOTE:

For detailed operation procedure, refer to

“READ CURRENT DATA FOR ENGINE”. <Ref.

to EN(H4DOTC)(diag)-34, Subaru Select Moni-

tor.>

Is the actual difference with

barometric pressure 50 mmHg

(6.7 kPa, 2.0 inHg, 0.97 psig) or

more?

Go to step 2.

Even if DTC is

detected, the cir-

cuit has returned to

a normal condition

at this time. Repro-

duce the failure,

and then perform

the diagnosis

again.

NOTE:

In this case, tem-

porary poor con-

tact of connector

may be the cause.

2

CHECK SECONDARY AIR PUMP.

1) Start the engine and warm up engine until

coolant temperature is higher than 75°C

(167°F).

2) Check whether the secondary air pump is

operating.

Is the secondary air pump oper-

ating?

Go to step 3.

Replace the sec-

ondary air combi-

nation valve LH.

<Ref. to

EC(H4DOTC)-22,

Secondary Air

Combination

Valve.>

3

CHECK HARNESS BETWEEN ECM AND

SECONDARY AIR PUMP RELAY CONNEC-

TOR.

1) Turn the ignition switch to OFF.

2) Remove the secondary air pump relay from

the relay box.

3) Measure the resistance between the sec-

ondary air pump relay connector and engine

ground terminals.

Connector & terminal

(F9) No. 13 — Engine ground:

Is the resistance 1 M

: or

more?

Go to step 4.

Repair the ground

short circuit of har-

ness between

ECM and second-

ary air pump relay

connector.

4

CHECK SECONDARY AIR PUMP RELAY.

Measure the resistance between the secondary

air pump relay terminals.

Terminals

No. 14 — No. 11:

Is the resistance 1 M

: or

more?

Repair the short

circuit of harness

to power supply

between second-

ary air pump relay

and secondary air

pump connector.

Replace the sec-

ondary air pump

relay. <Ref. to

EN(H4DOTC)(diag)

-8, Electrical Com-

ponent Location.>