Subaru Legacy IV (2008 year). Manual - part 366

EN(H4DOTC)(diag)-285

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

DA:DTC P2006 INTAKE MANIFOLD RUNNER CONTROL STUCK CLOSED

(BANK 1)

DTC DETECTING CONDITION:

• Immediately at fault recognition

• GENERAL DESCRIPTION <Ref. to GD(H4DOTC)-189, DTC P2006 INTAKE MANIFOLD RUNNER CON-

TROL STUCK CLOSED (BANK 1), Diagnostic Trouble Code (DTC) Detecting Criteria.>

CAUTION:

After repair or replacement of faulty parts, perform Clear Memory Mode <Ref. to EN(H4DOTC)(diag)-

52, OPERATION, Clear Memory Mode.>, and Inspection Mode <Ref. to EN(H4DOTC)(diag)-43, PRO-

CEDURE, Inspection Mode.>.

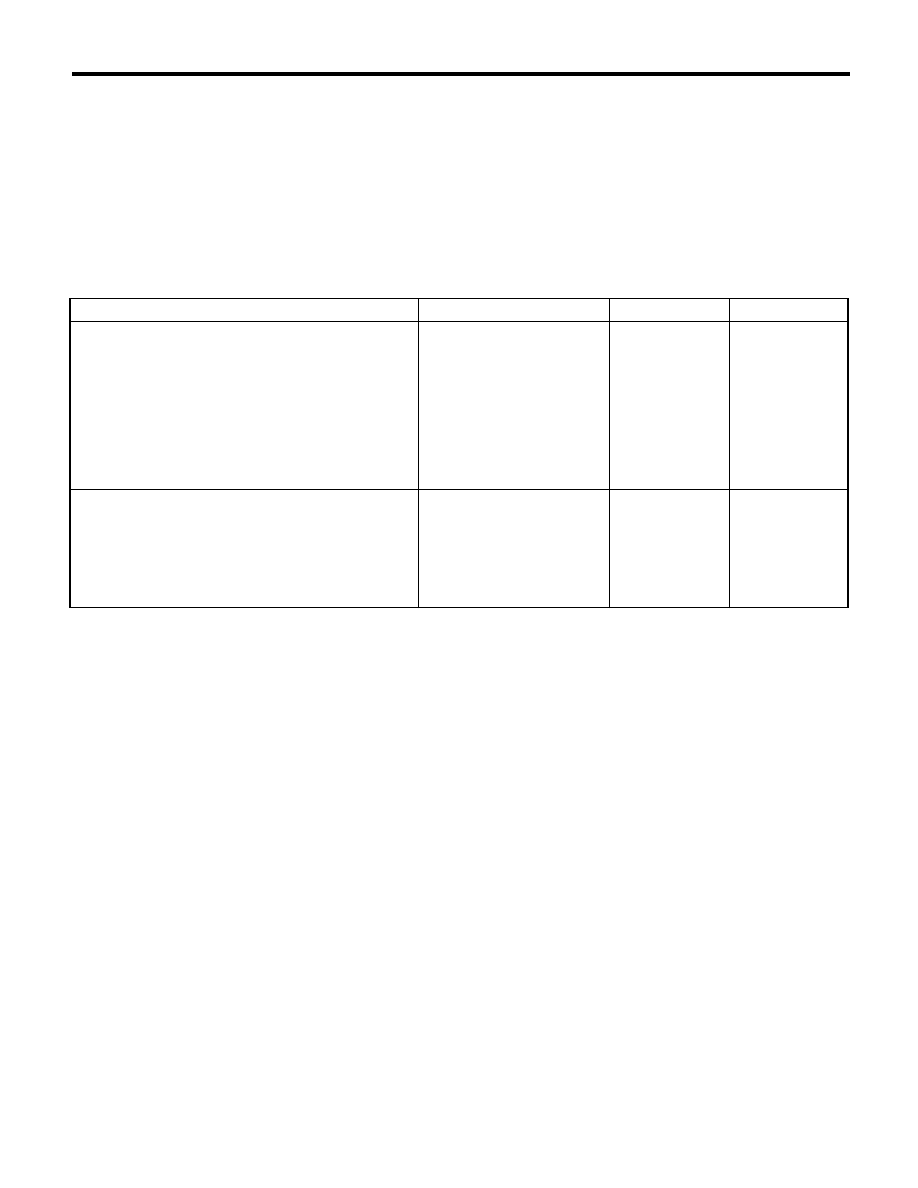

Step

Check

Yes

No

1

CHECK FOR ANY OTHER DTC ON DISPLAY. Is any other DTC displayed?

Check the appro-

priate DTC using

the “List of Diag-

nostic Trouble

Code (DTC)”.

<Ref. to

EN(H4DOTC)(diag)

-81, List of Diag-

nostic Trouble

Code (DTC).>

Go to step 2.

2

CHECK TUMBLE GENERATOR VALVE RH.

1) Remove the tumble generator valve assem-

bly RH.

2) Check the tumble generator valve body.

Is there any dirt or clogging with

foreign objects in the tumble

generator valve?

Clean the tumble

generator valve.

Replace the tum-

ble generator valve

assembly RH.

<Ref. to

FU(H4DOTC)-41,

Tumble Generator

Valve Assembly.>