Subaru Legacy IV (2008 year). Manual - part 168

EN(H4SO)(diag)-275

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

16

CHECK REAR OXYGEN SENSOR CONNEC-

TOR AND COUPLING CONNECTOR.

Has water entered the connec-

tor?

Completely

remove any water

inside.

Go to step 18.

17

CHECK FRONT OXYGEN (A/F) SENSOR

AND REAR OXYGEN SENSOR DATA.

1) Warm up the engine until engine coolant

temperature is higher than 75°C (167°F), then

keep the engine idling for 5 minutes or more.

2) Read the data of rear oxygen sensor signal

using Subaru Select Monitor or general scan

tool.

NOTE:

• SUBARU SELECT MONITOR

For detailed operation procedure, refer to

“READ CURRENT DATA FOR ENGINE”. <Ref.

to EN(H4SO)(diag)-33, Subaru Select Moni-

tor.>

• General Scan Tool

For detailed operation procedures, refer to the

general scan tool operation manual.

Is a voltage of 0.8 V or more

maintained for 5 minutes or

more?

Replace the front

oxygen (A/F) sen-

sor. <Ref. to

FU(H4SO)-35,

Front Oxygen (A/F)

Sensor.>

Go to step 18.

18

CHECK HARNESS BETWEEN ECM AND

REAR OXYGEN SENSOR CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connectors from ECM and

rear oxygen sensor.

3) Measure the resistance of harness between

ECM and rear oxygen sensor connector.

Connector & terminal

(B135) No. 4 — (E23) No. 3:

(B134) No. 29 — (E23) No. 4:

Is the resistance less than 1

:? Go to step 19.

Repair the harness

and connector.

NOTE:

In this case, repair

the following item:

• Open circuit in

harness between

ECM and rear oxy-

gen sensor con-

nector

• Poor contact of

coupling connector

19

CHECK HARNESS BETWEEN ECM AND

REAR OXYGEN SENSOR CONNECTOR.

1) Connect the connector to ECM.

2) Turn the ignition switch to ON.

3) Measure the voltage between rear oxygen

sensor connector and chassis ground.

Connector & terminal

(E23) No. 3 (+) — Chassis ground (–):

Is the voltage 0.2 — 0.5 V?

Replace the rear

oxygen sensor.

<Ref. to

FU(H4SO)-37,

Rear Oxygen Sen-

sor.>

Repair the harness

and connector.

NOTE:

In this case, repair

the following item:

• Open circuit of

harness between

the ECM and rear

oxygen sensor

• Poor contact in

ECM connector

• Poor contact of

coupling connector

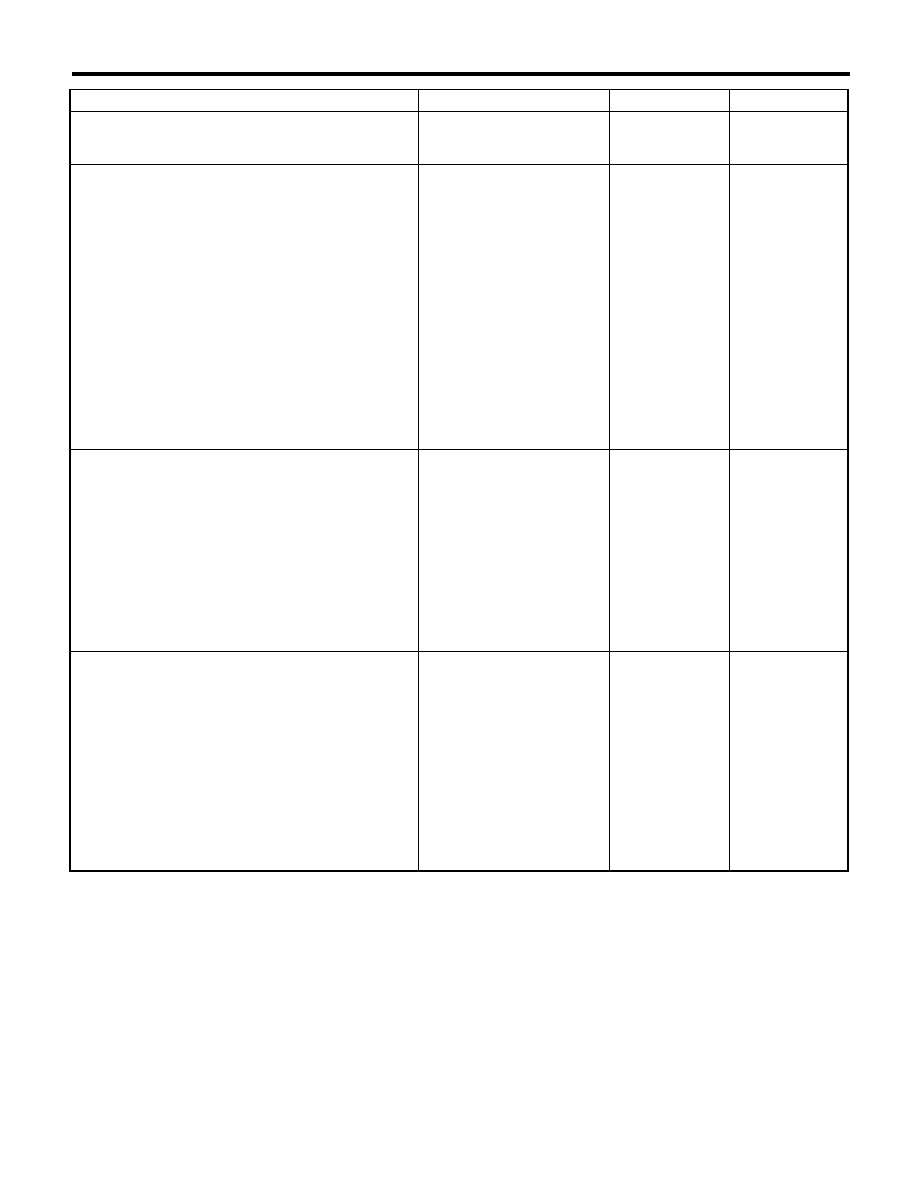

Step

Check

Yes

No