Subaru Legacy IV (2008 year). Manual - part 165

EN(H4SO)(diag)-263

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

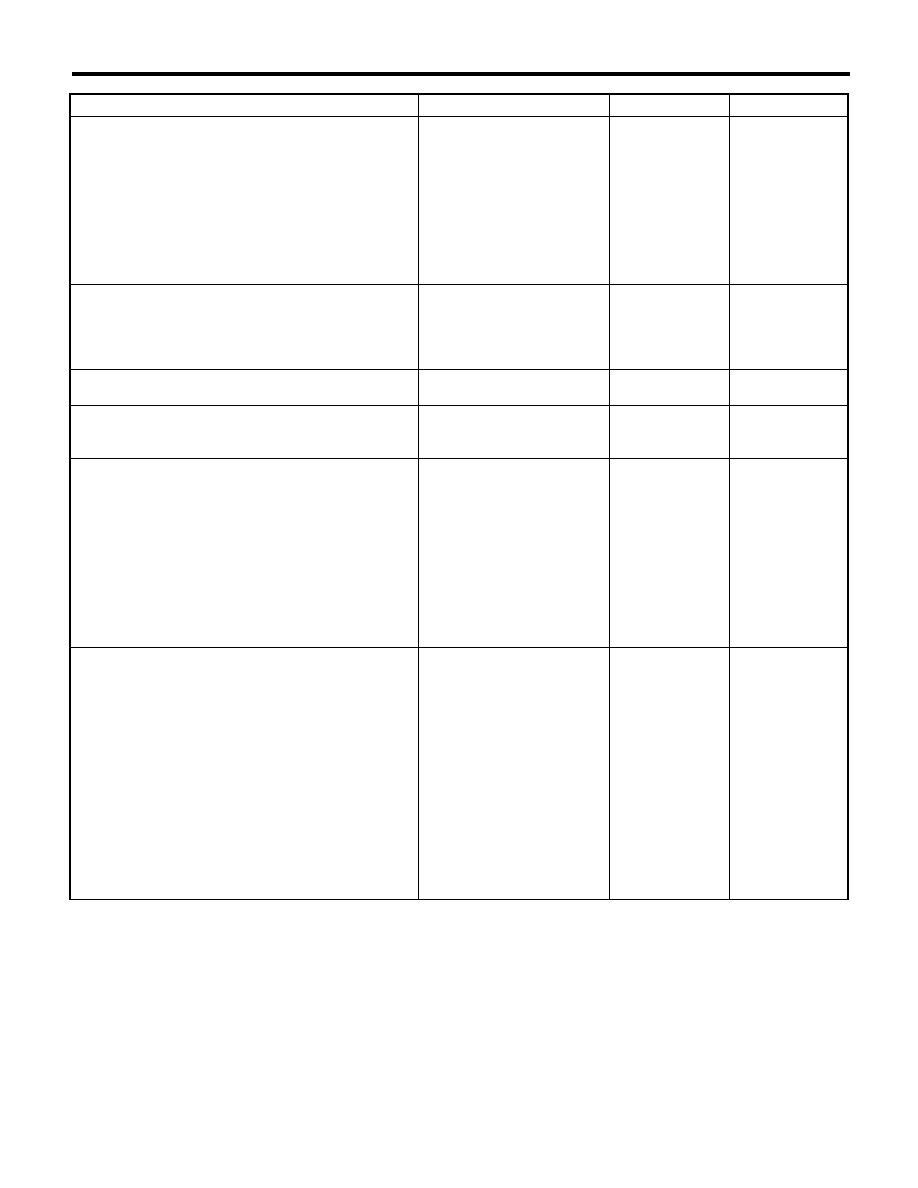

Step

Check

Yes

No

1

CHECK FOR ANY OTHER DTC ON DISPLAY. Is any other DTC displayed?

Check the appro-

priate DTC using

the “List of Diag-

nostic Trouble

Code (DTC)”.

<Ref. to

EN(H4SO)(diag)-

80, List of Diagnos-

tic Trouble Code

(DTC).>

Go to step 2.

2

CHECK ENGINE OIL.

Is there a proper amount of

engine oil?

Go to step 3.

Replace engine oil.

<Ref. to

LU(H4SO)-10,

REPLACEMENT,

Engine Oil.>

3

CHECK EXHAUST SYSTEM.

Are there holes or loose bolts

on exhaust system?

Repair the exhaust

system.

Go to step 4.

4

CHECK AIR INTAKE SYSTEM.

Are there holes, loose bolts or

disconnection of hose on air

intake system?

Repair the air

intake system.

Go to step 5.

5

CHECK FUEL PRESSURE.

WARNING:

Place “NO OPEN FLAMES” signs near the

working area.

CAUTION:

Be careful not to spill fuel.

Measure the fuel pressure. <Ref. to ME(H4SO)-

26, INSPECTION, Fuel Pressure.>

CAUTION:

Release fuel pressure before removing the

fuel pressure gauge.

Is the measured value 339.5 —

360.5 kPa (3.5 — 3.7 kg/cm

2

,

49 — 52 psi)?

Go to step 6.

Repair the follow-

ing item.

Fuel pressure is

too high:

• Clogged fuel line

or bent hose

Fuel pressure is

too low:

• Improper fuel

pump discharge

• Clogged fuel line

6

CHECK ENGINE COOLANT TEMPERATURE

SENSOR.

1) Start the engine and warm up completely.

2) Read the data of engine coolant tempera-

ture sensor signal using Subaru Select Monitor

or general scan tool.

NOTE:

• SUBARU SELECT MONITOR

For detailed operation procedure, refer to

“READ CURRENT DATA FOR ENGINE”. <Ref.

to EN(H4SO)(diag)-33, Subaru Select Moni-

tor.>

• General Scan Tool

For detailed operation procedures, refer to the

general scan tool operation manual.

Is the engine coolant tempera-

ture 75°C (167°F) or higher?

Go to step 7.

Replace the

engine coolant

temperature sen-

sor. <Ref. to

FU(H4SO)-22,

Engine Coolant

Temperature Sen-

sor.>