Subaru Legacy IV (2008 year). Manual - part 149

EN(H4SO)(diag)-199

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

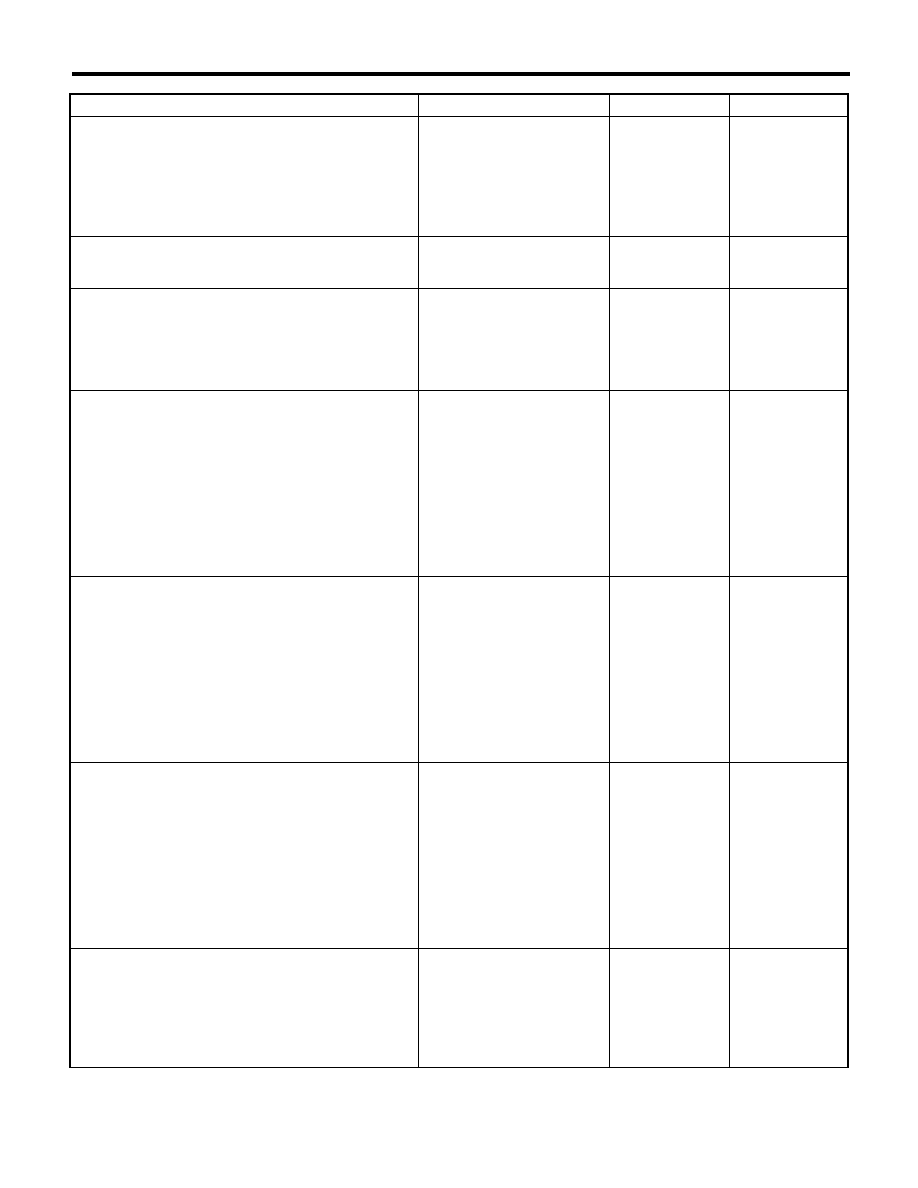

Step

Check

Yes

No

1

CHECK FUEL FILLER CAP.

1) Turn the ignition switch to OFF.

2) Check the fuel filler cap.

NOTE:

The DTC is stored in memory if fuel filler cap is

or was loose or if the cap chain has caught while

tightening.

Is the fuel filler cap tightened

securely?

Go to step 2.

Tighten fuel filler

cap securely.

2

CHECK FUEL FILLER CAP.

Is the fuel filler cap genuine?

Go to step 3.

Replace with a

genuine fuel filler

cap.

3

CHECK FUEL FILLER PIPE GASKET.

Is there any damage to the seal

between fuel filler cap and fuel

filler pipe?

Repair or replace

the fuel filler cap

and fuel filler pipe.

<Ref. to

FU(H4SO)-52,

Fuel Filler Pipe.>

Go to step 4.

4

CHECK DRAIN VALVE.

1) Connect the delivery (test) mode connector.

2) Turn the ignition switch to ON.

3) Operate the drain valve using the Subaru

Select Monitor.

NOTE:

The drain valve can be operated using Subaru

Select Monitor. For the procedures, refer to

“Compulsory Valve Operation Check Mode”.

<Ref. to EN(H4SO)(diag)-51, Compulsory

Valve Operation Check Mode.>

Does the drain valve operate?

Go to step 5.

Replace the drain

valve. <Ref. to

EC(H4SO)-16,

Drain Valve.>

5

CHECK PURGE CONTROL SOLENOID

VALVE.

Operate the purge control solenoid valve using

the Subaru Select Monitor.

NOTE:

Purge control solenoid valve operation can be

executed using Subaru Select Monitor. For the

procedures, refer to “Compulsory Valve Opera-

tion Check Mode”. <Ref. to EN(H4SO)(diag)-

51, Compulsory Valve Operation Check

Mode.>

Does the purge control sole-

noid valve operate?

Go to step 6.

Replace the purge

control solenoid

valve. <Ref. to

EC(H4SO)-7,

Purge Control

Solenoid Valve.>

6

CHECK PRESSURE CONTROL SOLENOID

VALVE.

Operate the pressure control solenoid valve

using the Subaru Select Monitor.

NOTE:

The pressure control solenoid valve operation

can be executed using the Subaru Select Mon-

itor. For the procedures, refer to “Compulsory

Valve Operation Check Mode”. <Ref. to

EN(H4SO)(diag)-51, Compulsory Valve Opera-

tion Check Mode.>

Does the pressure control sole-

noid valve operate?

Go to step 7.

Replace the pres-

sure control sole-

noid valve. <Ref. to

EC(H4SO)-13,

Pressure Control

Solenoid Valve.>

7

CHECK EVAPORATIVE EMISSION CON-

TROL SYSTEM LINE.

1) Turn the ignition switch to OFF.

2) Disconnect the delivery (test) mode connec-

tor.

Is there any hole of more than

1.0 mm (0.04 in) dia. on evapo-

ration line?

Repair or replace

the evaporation

line. <Ref. to

FU(H4SO)-65,

Fuel Delivery and

Evaporation

Lines.>

Go to step 8.