Subaru Legacy IV (2008 year). Manual - part 98

SC(H4SO)-16

Generator

STARTING/CHARGING SYSTEMS

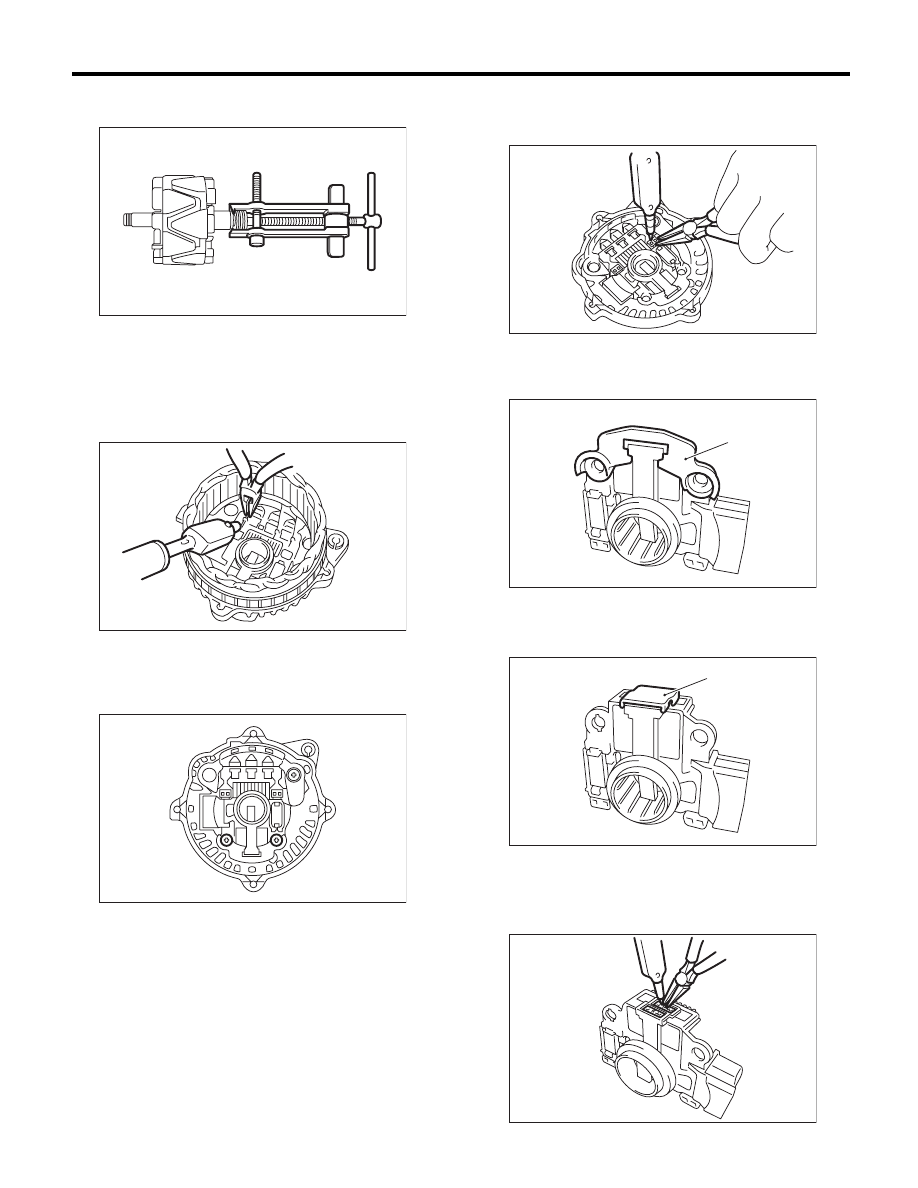

6) Using the bearing puller, remove the bearings

from the rotor.

7) Disconnect the connection between the rectifier

and stator coil, then remove the stator coil.

CAUTION:

The rectifier is easily damaged by heat. Do not

allow a 180 — 270 W soldering iron to contact

the terminals for 5 seconds or more at a time.

8) Use the following procedures to remove the IC

regulator.

(1) Remove the screws which secure the IC

regulator to the rear cover.

(2) Disconnect the connection between the IC

regulator and rectifier, then remove the IC reg-

ulator.

9) Use the following procedures to remove the

brush.

(1) Remove the cover A.

(2) Remove the cover B.

(3) Disconnect the connection and remove the

brush.

SC-00046

SC-00083

SC-00084

(A) Cover A

(A) Cover B

SC-00085

SC-00086

(A)

SC-00087

(A)

SC-00088