Subaru Legacy IV (2008 year). Manual - part 90

LU(H4SO)-17

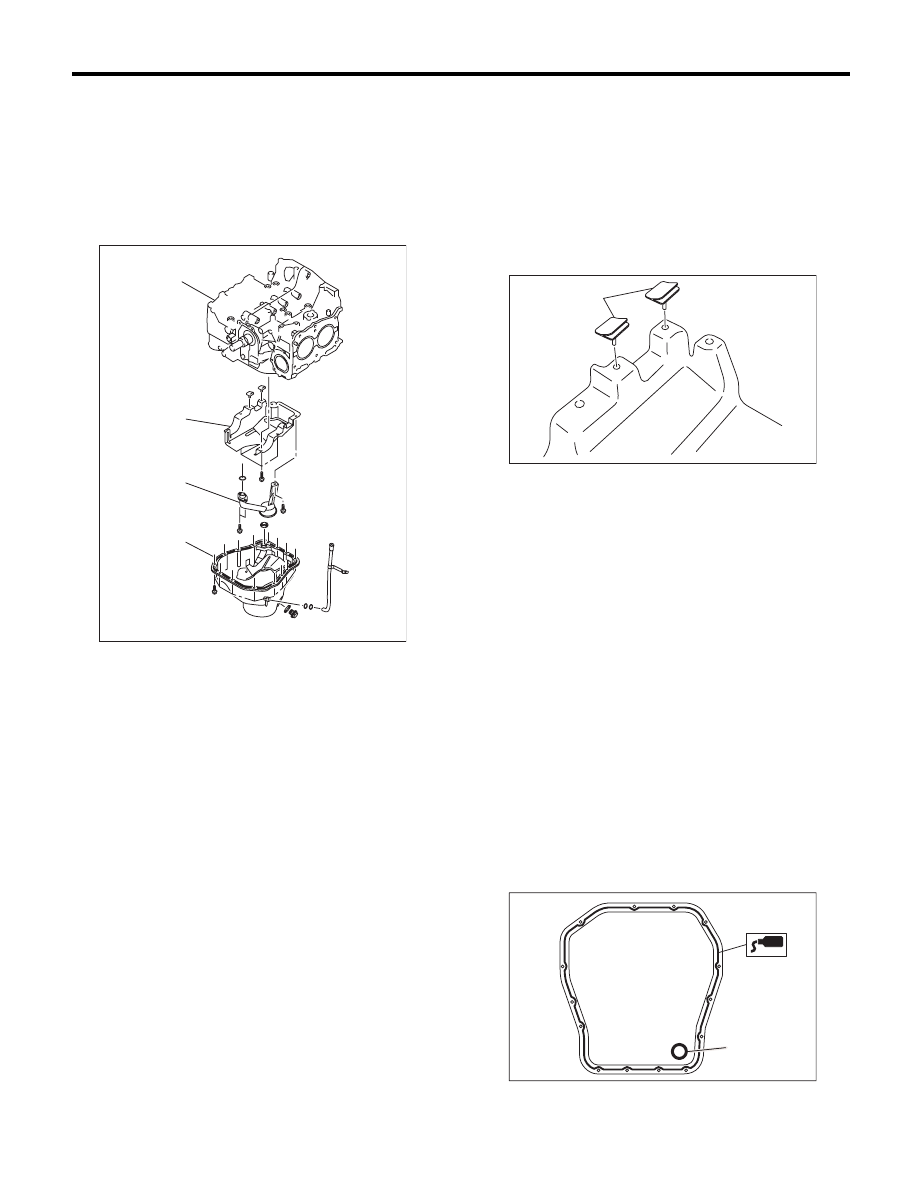

Oil Pan and Strainer

LUBRICATION

18) Insert the oil pan cutter blade into the gap be-

tween cylinder block and oil pan, and remove the

oil pan.

CAUTION:

Do not use a screwdriver or similar tool in place

of oil pan cutter.

19) Remove the oil strainer.

20) Remove the baffle plate.

B: INSTALLATION

NOTE:

Before installing the oil pan, clean the mating sur-

face of oil pan and engine block.

1) Make sure that the seals (A) are installed se-

curely on the baffle plate in a direction as shown in

the figure below.

NOTE:

Use new seals.

2) Install the baffle plate.

Tightening torque:

6.4 N·m (0.7 kgf-m, 4.7 ft-lb)

3) Install the oil strainer to the cylinder block.

NOTE:

Use new O-rings.

Tightening torque:

10 N·m (1.0 kgf-m, 7.4 ft-lb)

4) Tighten the oil strainer stay together with the baf-

fle plate.

Tightening torque:

6.4 N·m (0.7 kgf-m, 4.7 ft-lb)

5) Apply liquid gasket to the mating surfaces of oil

pan, and install the oil pan.

NOTE:

• Use a new gasket.

• Install within 5 min. after applying liquid gasket.

Liquid gasket:

THREE BOND 1217G (Part No. K0877Y0100)

or equivalent

(A) Oil pan

(B) Oil strainer

(C) Baffle plate

(D) Cylinder block

(A)

(C)

(D)

(B)

LU-02334

(A) Gasket

LU-00052

(A)

LU-02353

(A)