Subaru Legacy IV (2008 year). Manual - part 79

CO(H4SO)-2

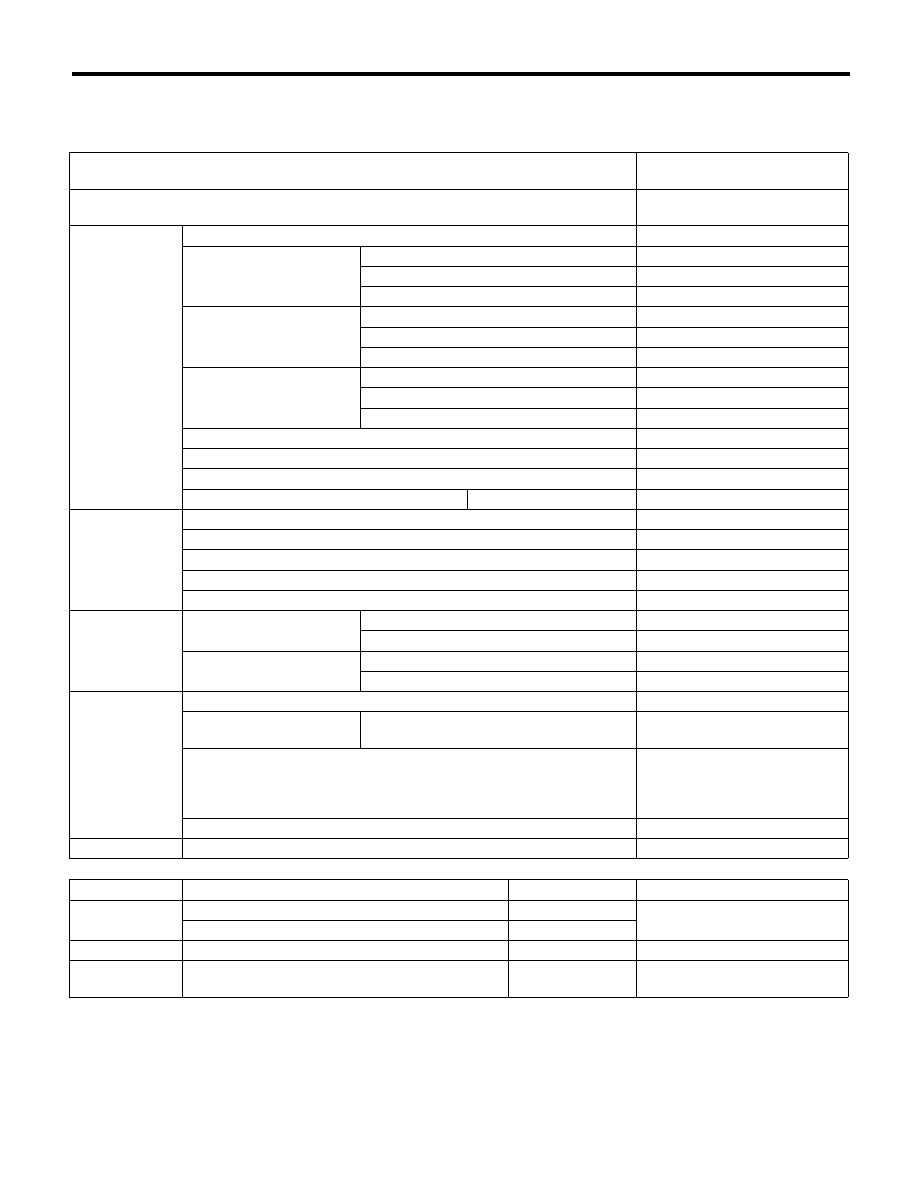

General Description

COOLING

1. General Description

A: SPECIFICATION

Cooling system

Electric fan + Forced engine

coolant circulation system

Total engine coolant capacity

2 (US qt, Imp qt)

MT: approx. 6.4 (6.8, 5.6)

AT: Approx. 6.3 (6.7, 5.5)

Water pump

Type

Centrifugal impeller type

Discharge performance I

Discharge rate

2 (US gal, Imp gal) /min.

20 (5.3, 4.4)

Pump speed — Discharge pressure

760 rpm — 2.9 kPa (0.3 mAq)

Engine coolant temperature

80°C (176°F)

Discharge performance II

Discharge rate

2 (US gal, Imp gal) /min.

100 (26.4, 22.0)

Pump speed — Discharge pressure

3,000 rpm — 49 kPa (5.0 mAq)

Engine coolant temperature

80°C (176°F)

Discharge performance III

Discharge rate

2 (US gal, Imp gal) /min.

200 (52.8, 44.0)

Pump speed — Discharge pressure

6,000 rpm — 225.4 kPa (23 mAq)

Engine coolant temperature

80°C (176°F)

Impeller diameter

mm (in)

76 (2.99)

Number of impeller vanes

8

Pump pulley diameter

mm (in)

60 (2.36)

Clearance between impeller and case

Standard

mm (in)

0.5 — 1.5 (0.020 — 0.060)

Thermostat

Type

Wax pellet type

Starting temperature to open

80 — 84°C (176 — 183°F)

Fully opens

95°C (203°F)

Valve lift

mm (in)

9.0 (0.354) or more

Valve bore

mm (in)

35 (1.38)

Radiator fan

Motor input

Main fan

90 W

Sub fan

90 W

Fan diameter / Blade

Main fan

300 mm (11.81 in)/4

Sub fan

300 mm (11.81 in)/5

Radiator

Type

Down flow, pressure type

Core dimensions

Width × Height × Thickness

mm (in)

687.4 × 340 × 16

(27.06 × 13.39 × 0.63)

Pressure range in which cap valve is open

kPa (kg/cm

2

, psi)

Above: 108

r15 or more

(1.1

r0.15, 16r2)

Below: –1.0 to –4.9 or less

(–0.01 — –0.05, –0.1 — –0.7)

Fins

Corrugated fin type

Reservoir tank

Capacity

2 (US qt, Imp qt)

0.45 (0.48, 0.40)

Recommended materials

Item number

Alternative

Coolant

SUBARU SUPER COOLANT (Concentrated type)

—

—

SUBARU SUPER COOLANT (Diluted type)

K0670Y0000

Water for dilution

Distilled water

—

Soft water or tap water

Cooling system

protective agent

Cooling system conditioner

SOA345001

—