SsangYong Rexton. Manual - part 676

SSANGYONG Y200

9D-18 BODY ELECTRICAL

YAD9D260

YAD9D270

YAD9D280

Fuel System

Gauge of fuel

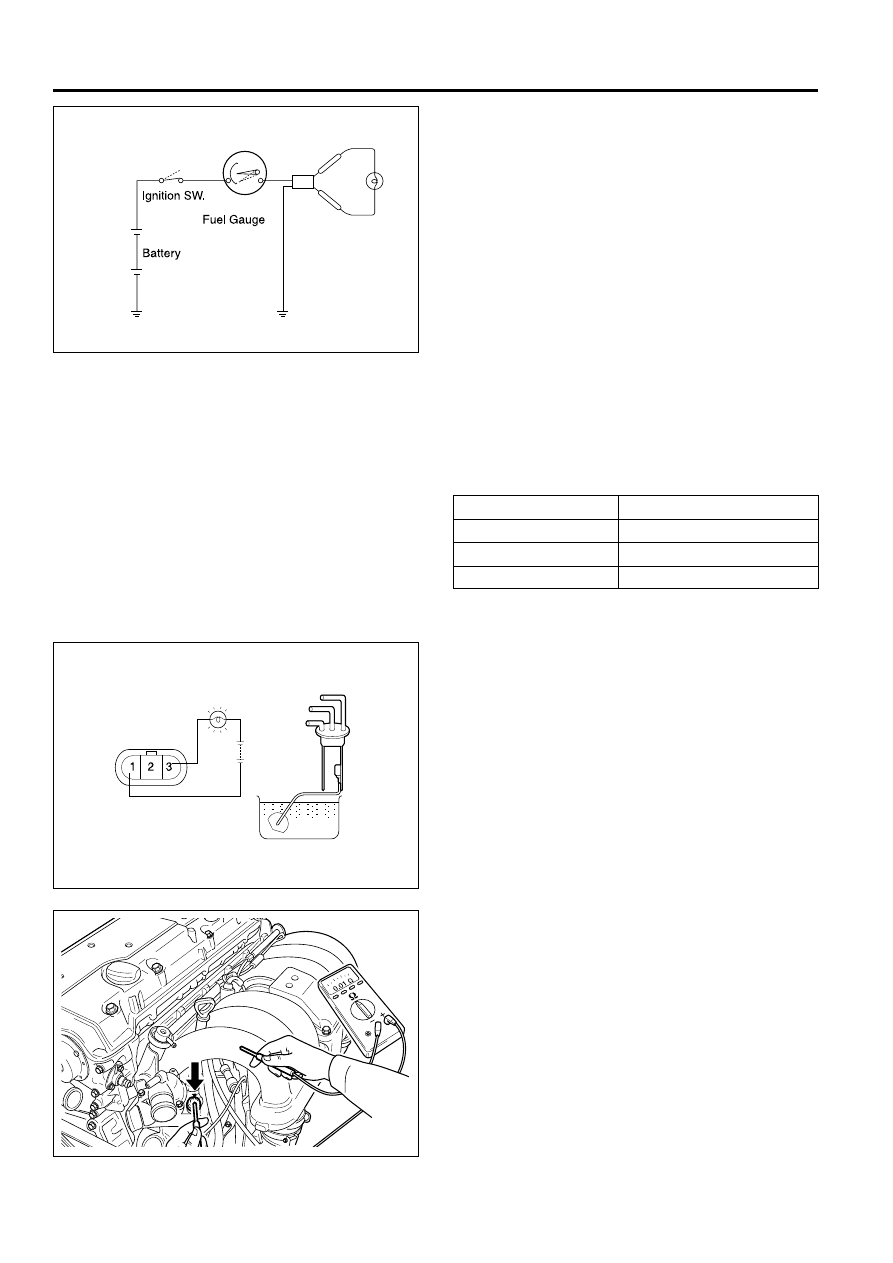

1. Separate connector of fuel sender.

2. Ground connector (B11, B14) of direction of

harness through bulb (12 V, 3.4 W).

3. Turn the start switch on.

4. See if bulb of testing turn on, and see if indicator

of fuel gauge gradually move to position of ‘F’.

Check resistence of fuel sender

1. Put float on the position of ‘F’ and ‘E’, and check

resistence between B11 and B14.

2. While float is moving from position of ‘E’ to

position of ‘F’, check if resistence change

gradually.

Position of float

E

1/2

F

Specified resistence

approximately 285

Ω

approximately 101.5

Ω

approximately 40

Ω

Fuel sender

1. Connect testing bulb (12 V. 3.4 W) of fuel gauge

terminal deepen thermister in the water.

2. See if thermister is deepened in the water, light is

off, and see if thermister get out of water, light is

on.

Notice:

•

If malfunction may happen, replace fuel sender

assembly.

•

After this testing have done, before fuel sender

i s i n s t a l l e d , f u e l s e n d e r s h o u l d d r y u p

completely.

Gauge of Temp

1. Separate wiring connector of water coolant in the

engine room.

2. Ground between testing bulb (12 V,3.4 W) and

connector to harness in a series.

3. Turn ignition switch on.

4. See if testing light turns on or not, check if gauge

of water temp operate or not.