SsangYong Rexton. Manual - part 389

DIESEL ENGINE MECHANICAL 1B3-131

SSANGYONG Y200

Tools Required

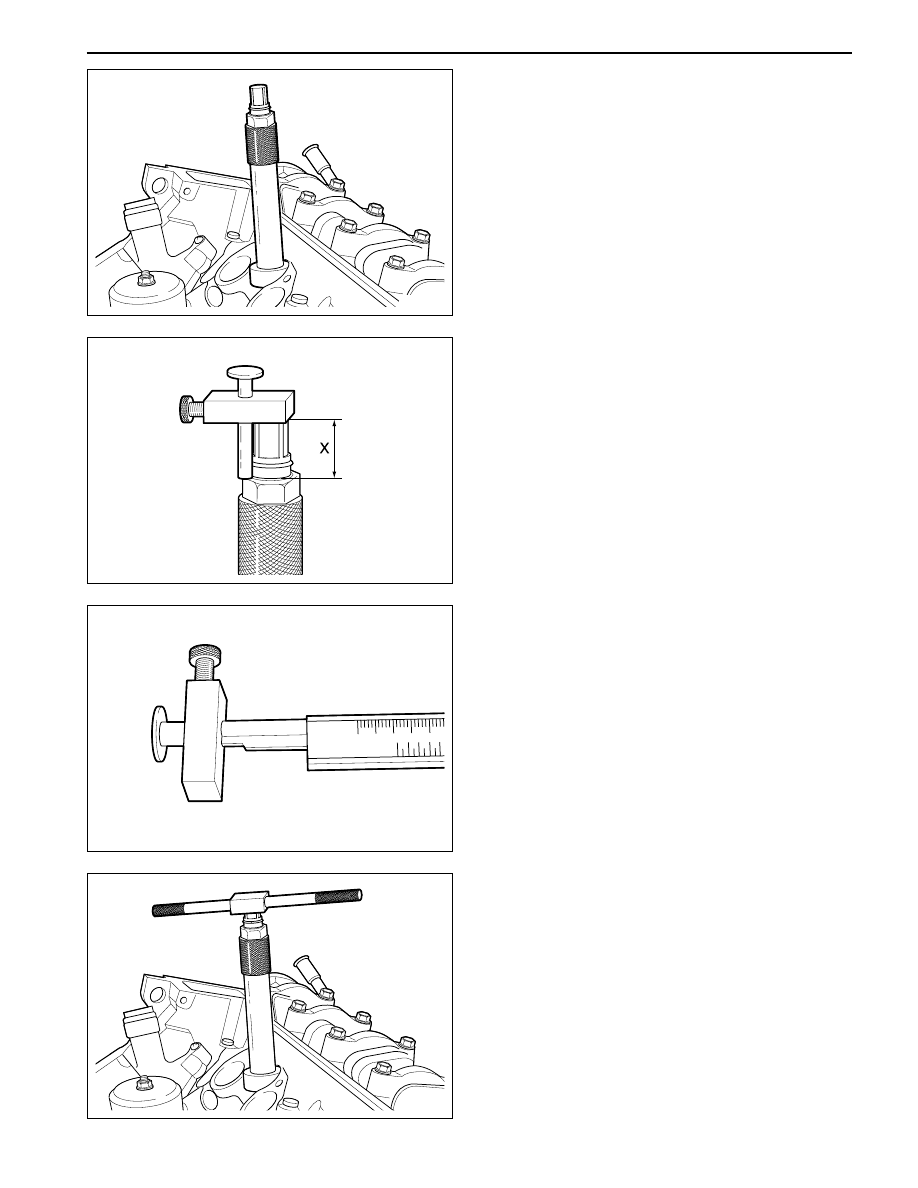

601 589 00 66 00

Counter Sink

607 589 00 23 00

Height Gauge

Milling of the Prechamber Sealing Surface

1. Remove the injection nozzle.

2. Remove the prechamber.

3. Cover the prechamber bore to avoid any chips

dropping into the combustion chamber.

4. Remove the protective sleeve from the counter sink

601 589 00 60 00 and rotate the counter sink 601

589 00 60 00 into the prechamber bore to be

machined as far as the stop.

7. Mount the turning tool onto the counter sink 601

589 00 60 00 and rotate to the right approx. 5

revolutions by applying slight pressure.

6. Measure the ‘X’ by using a vernier caliper.

5. Maintain size ‘X’ from the top edge of mandrel to

the top edge of the sleeve with the height gauge

667 589 00 23 00.

YAD1BJ50

YAD1BJ60

YAD1BJ70

YAD1BJ80