SsangYong Rexton. Manual - part 336

M161 ENGINE MECHANICAL 1B2-27

SSANGYONG Y200

YAD1B6D0

YAD1B6E0

YAD1B6F0

YAD1B6G0

Tools Required

617 589 00 10 00 Allen Wrench Socket

116 589 20 33 00

Sliding Hammer

116 589 01 34 00

Threaded Pin

111 589 03 15 00

Holding Pin

Removal & Installation Procedure

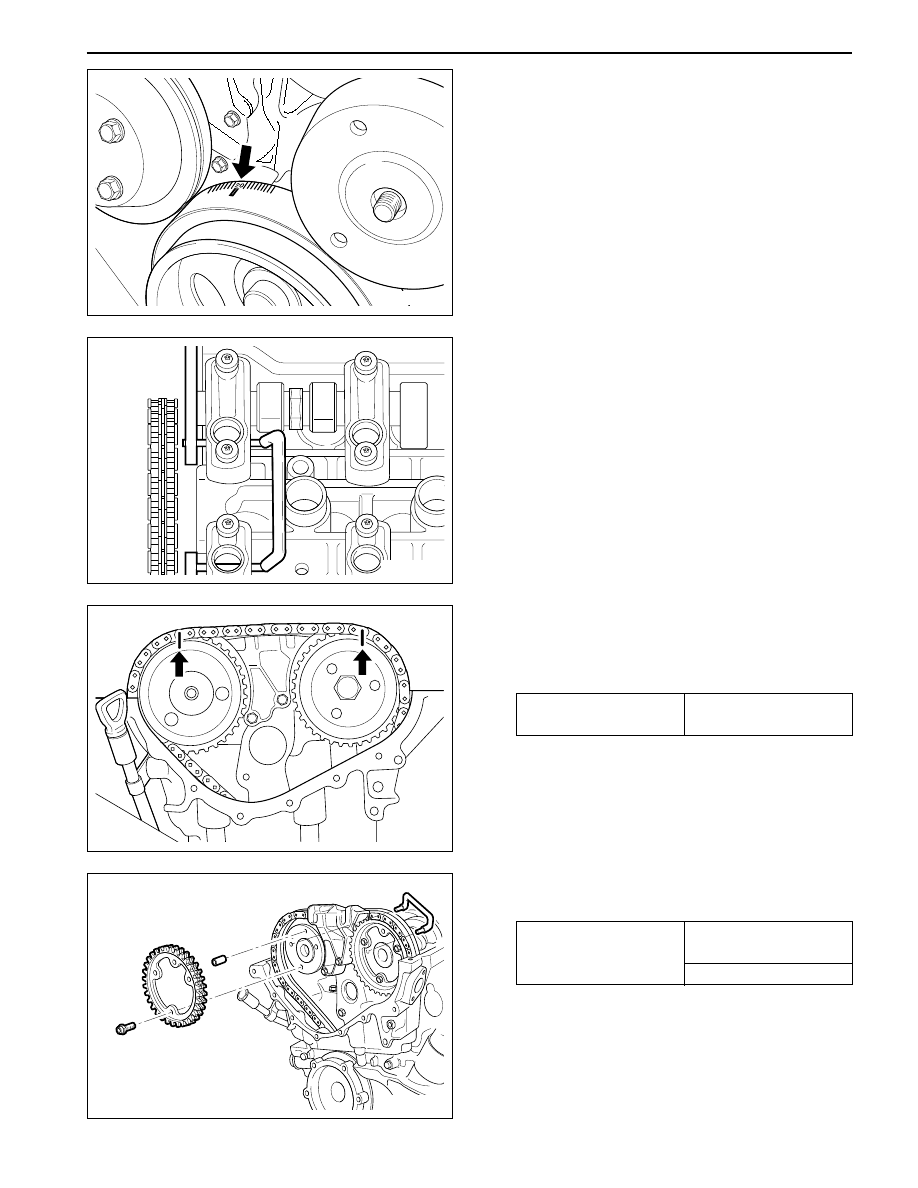

1. Rotate the crankshaft so that the piston of number

1 cylinder is at ATDC 20.

5. Remove the exhaust camshaft sprocket.

Installation Notice

Notice: The flange bolt is designed to be used

only once, so always replace with new one.

3. Put the alignment marks (arrows) on the timing

chain and camshaft sprocket.

4. Remove the chain tensioner.

Installation Notice

2. Put the holding pin 111 589 03 15 00 into the cam-

shaft bearing cap (number 1, 6).

Tightening Torque

1st step: 18 - 22 N•m

(13 - 16 lb-ft)

2nd step: 60° ± 5°

Tightening Torque

72 - 88 N•m

(53 - 65 lb-ft)