SsangYong Stavic / SsangYong Rodius (2005 year). Manual - part 307

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

42

DC 5-SPEED AUTOMATIC TRANSMISSION

STAVIC - 2004.09

4A

Self diagnostic 11

Selector lever unit

Instrument panel

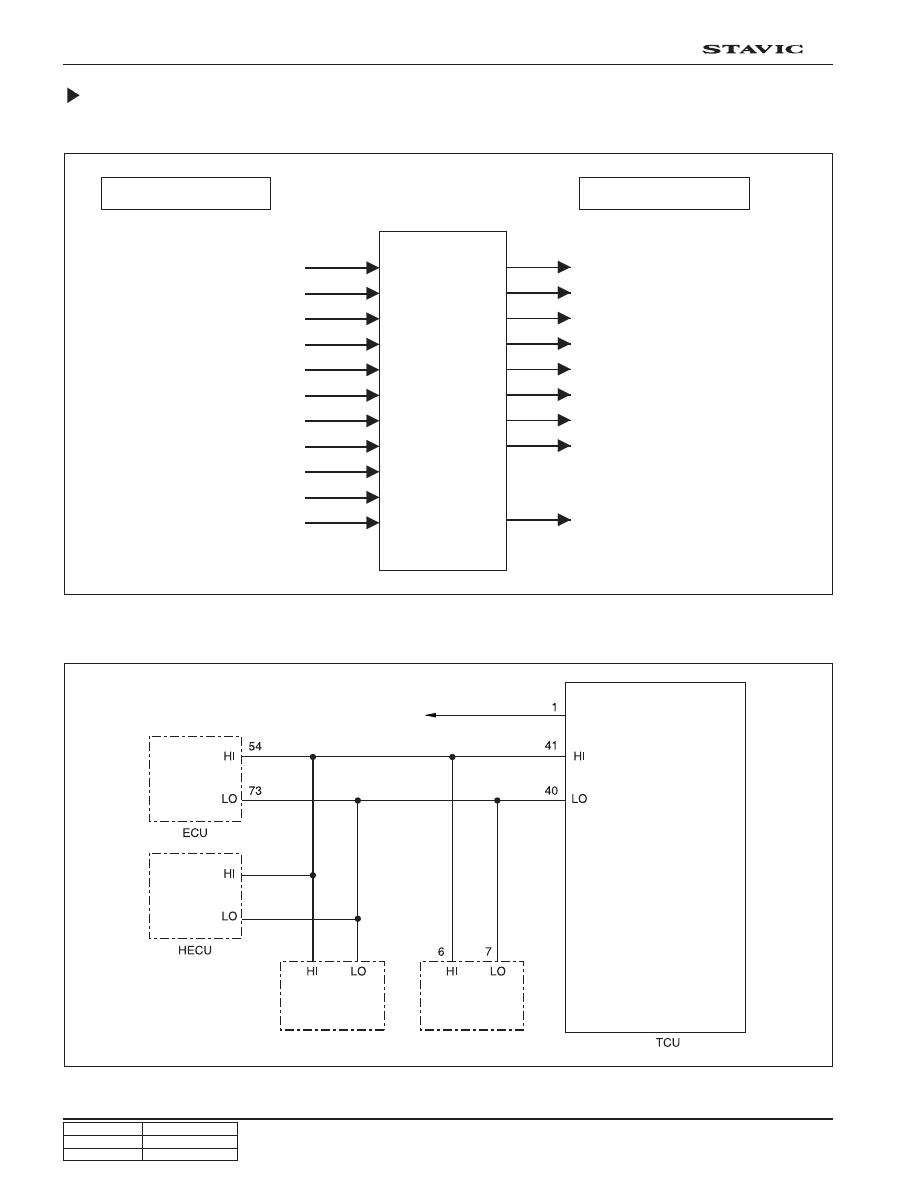

CAN (Controller Area Network )

Function

Circuit diagram

CAN input signal

CAN output signal

TCU

Accelerator pedal position

Wheel speed (all wheels)

Engine rpm, Engine torque

Coolant temperature

Downshift

Speed control (constant)

Meshed gear

2nd gear start up control

Selected gear in transfer case

Selector lever position

Odometer (I/P)

Selected gear

Shifted status

Lock-up clutch status

Automatic transmission

Kick-down status

Driving conditions

Engine torque control

Dangerous status (changes to

emergency mode when

overloading, dangerous conditions,

and internal fault exists)

ATF Temperature