SsangYong Stavic / SsangYong Rodius (2005 year). Manual - part 294

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

24

FFH & PTC

STAVIC - 2004.09

3B

Fuel Feeding Process

Fuel Feeding job should be followed after changing FFH assy or after fuel line job.

[Notice]

Without feeding job, FFH system could make white

smoke with abnormal noise.

3. If the fuel is sprayed out, connect the fuel pipe to

FFH assembly and keep the engine running for

1 minute.

4. Connect the ambient temperature connector.

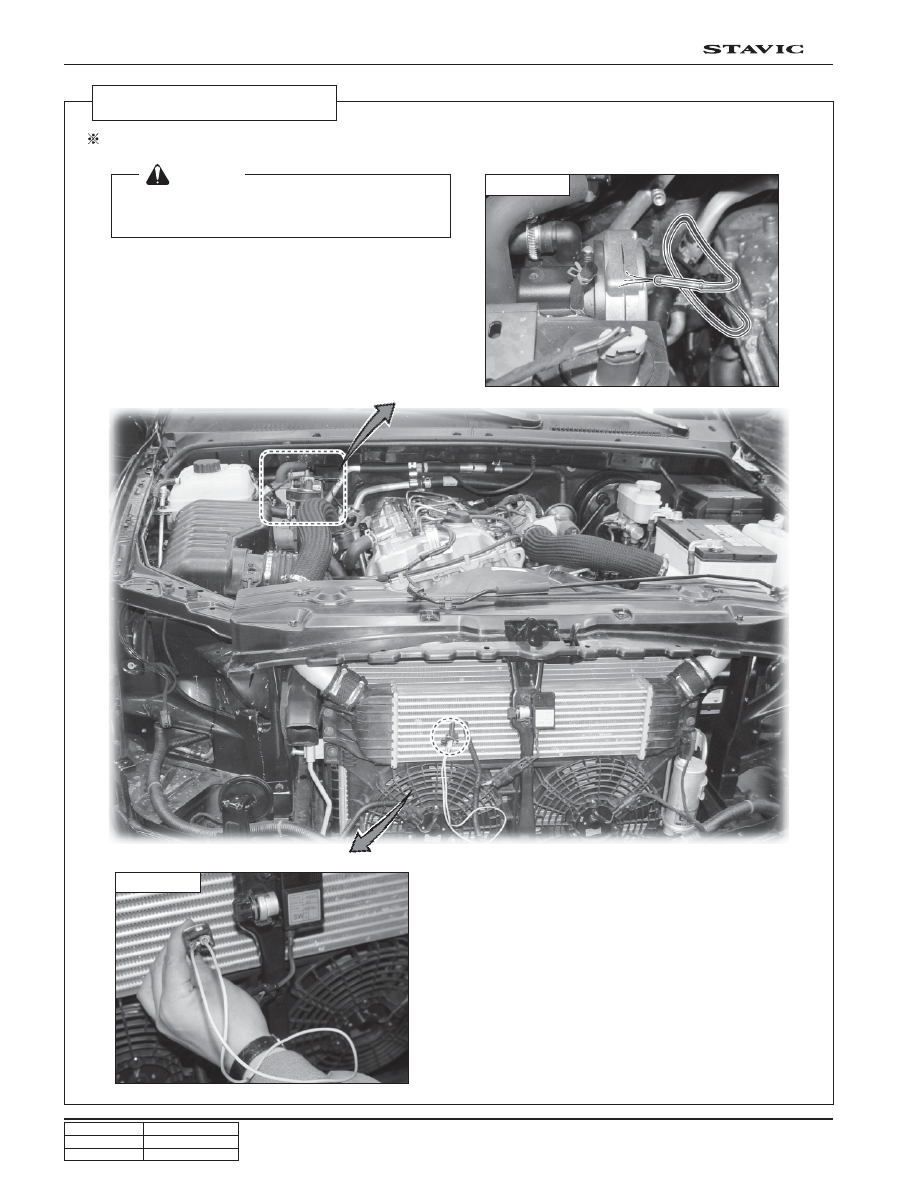

1. Disconnect the ambient temperature switch as

shown in picture (A).

2. Check if the fuel comes out after engine starting

as the FFH fuel supply hose is disconnected.

(Picture B)

Picture B

Picture A