SsangYong Stavic / SsangYong Rodius (2005 year). Manual - part 83

DI02-7

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

ENGINE HOUSING

DI ENG SM - 2004.9

10. Remove the cylinder head.

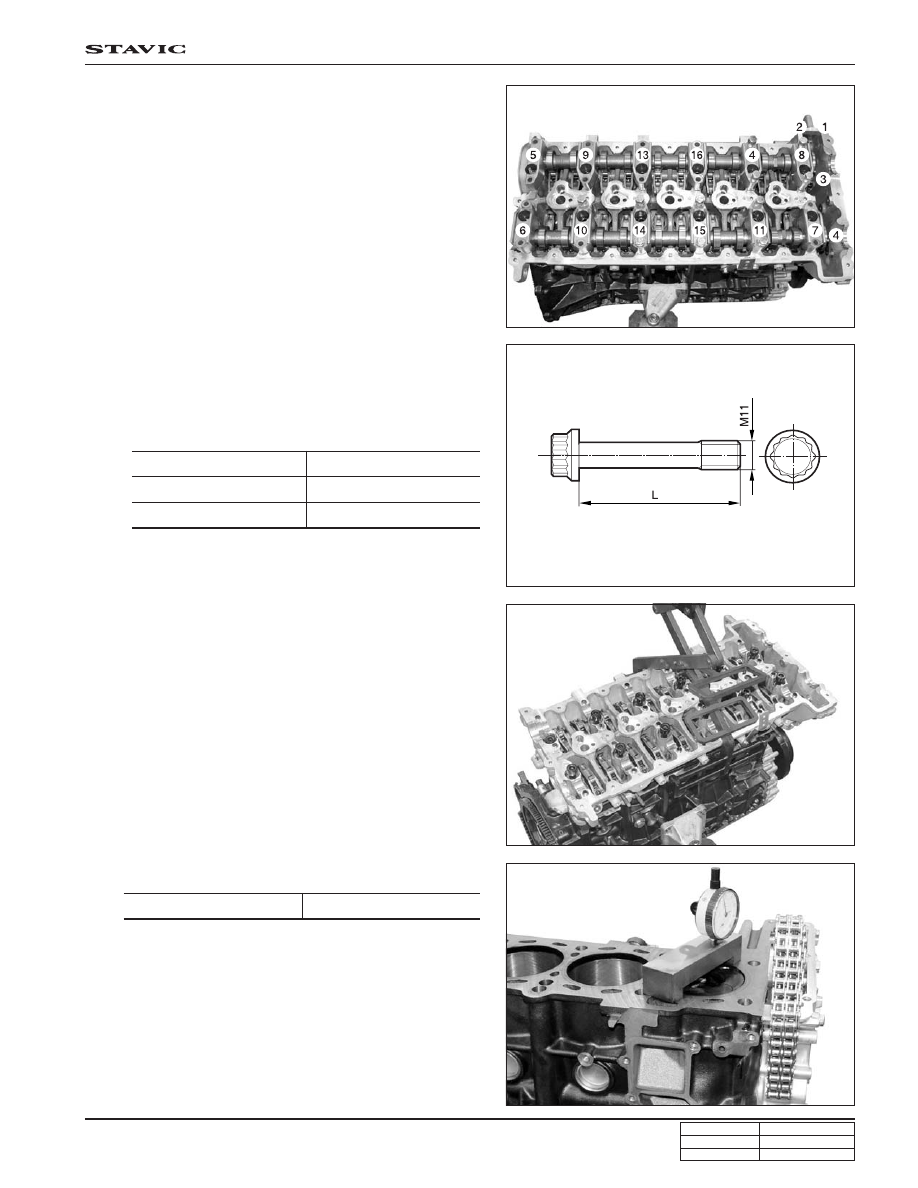

11. Measure the piston protrusion from the mating surface.

9. Measure the length of cylinder head bolts.

Installation Notice

•

If the maximum length is exceeded by 2 mm,

replace the cylinder head bolt.

8. Remove the cylinder head bolts according to the

numerical sequence.

M8 x 25

: 2 EA

M8 x 50

: 2 EA

M12 x 177 : 11 EA

M12 x 158 : 1 EA

(Vacuum pump side)

Notice

•

Inspect the cylinder head surface.

•

Store the removed injectors and glow plugs so that

they will not be damaged.

Length when new

177 mm

158 mm

Maximum Limit

179 mm

160 mm

Standard

0.765 ~ 1.055 mm