SsangYong Korando III (2010 year). Manual - part 340

06-8

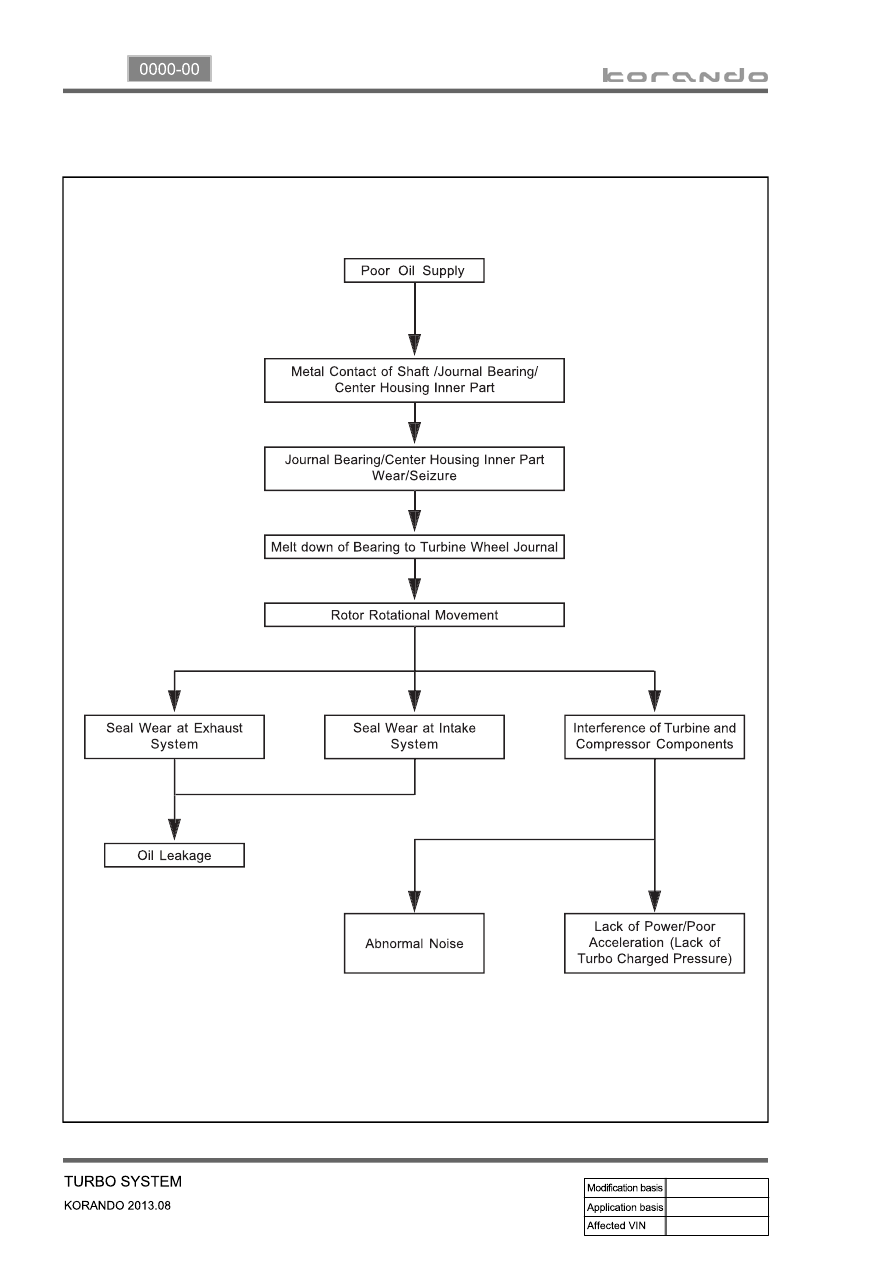

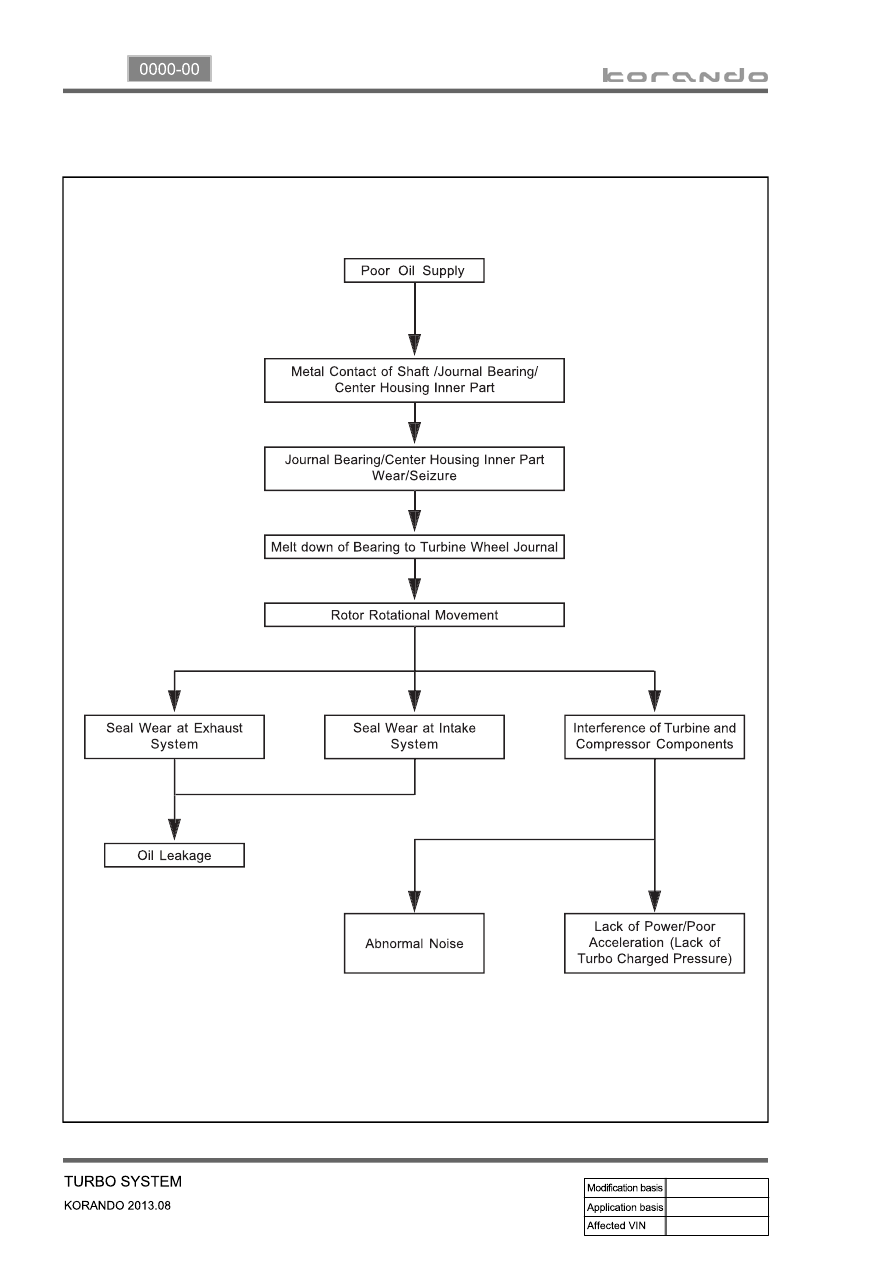

Oil Pump Defect: Rapid over-loaded driving after replacing oil filter and oil and clogging of oil line.

2.

|

|

|

06-8 Oil Pump Defect: Rapid over-loaded driving after replacing oil filter and oil and clogging of oil line. 2. |