SsangYong Korando II (1996-2006 year). Manual - part 443

SSANGYONG MY2002

9I-2 WATERLEAKS

Description

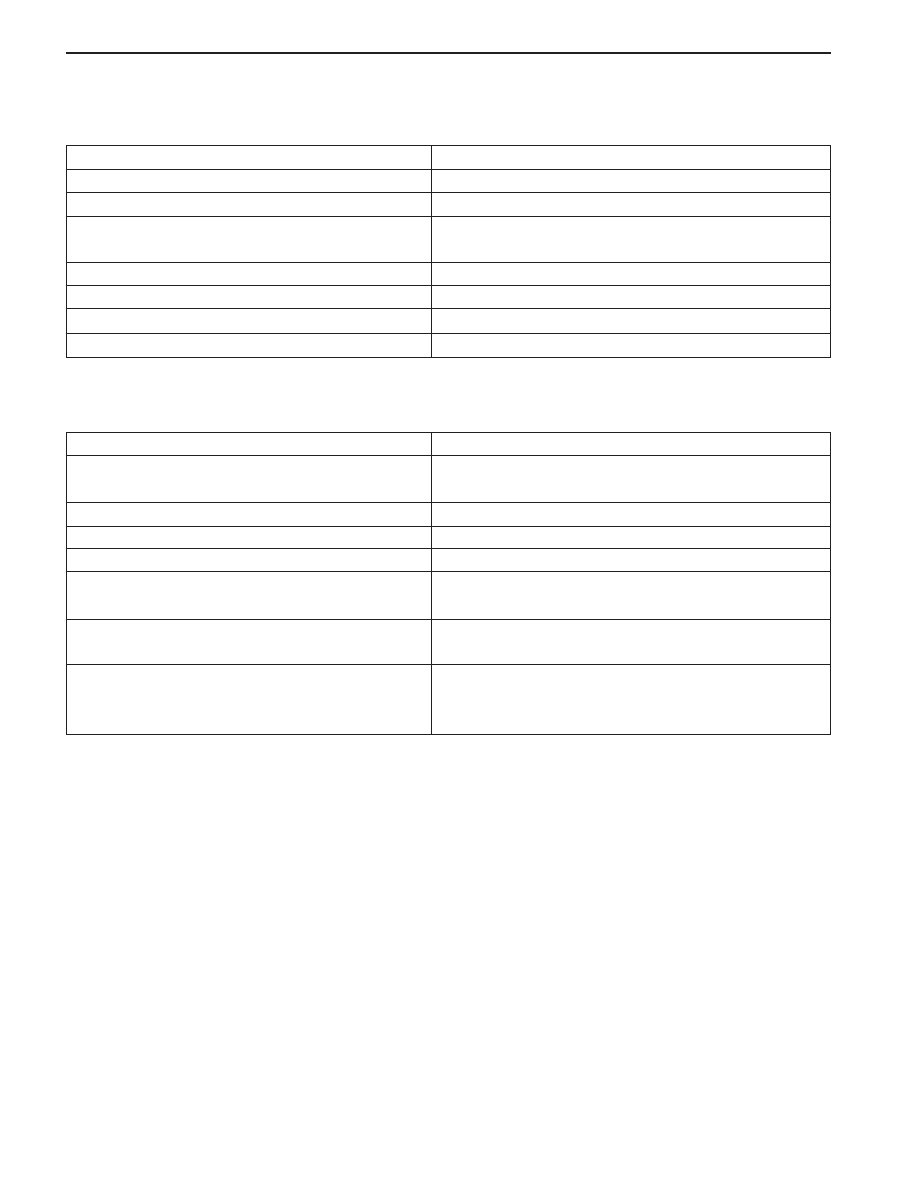

SPECIFICATIONS

RECOMMENDED MATERIALS FOR WATERLEAK REPAIRS

WATERTEST STAND SPECIFICATIONS

Windshield, back window

Metal joints

Ventilation ducts

Small cracks and pin holes

Large holes

Weatherstrips

Bolts, studs, and screws

Leak Areas

Repair Materials

Urethane adhesive, caulking kit, or the equivalent

Brushable seam sealer which can be painted

3M

TM

Auto Bedding and Glazing Compound or the

equivalent

3M

TM

Drip-Check Sealer or the equivalent

3M

TM

Automotive Joint and Seam Sealer

3M

TM

08011 Weatherstrip Adhesive or the equivalent

Strip caulk

Nozzle Type

Nozzle Height

Volume of Flow

Pressure

Windshield and A-Pillar Test Stand Position

B-Pillar Test Stand Position

Back Window and Rear Deck Lid Test Stand

Position

Application

Full jet spray nozzle #1/2 GG-25 or equivalent with a 60 °

included angle

Approximately 1,600 mm (63.0 in.) from the floor

14 L (3.7 gal) per minute

155 kPa (22.5 psi) measured at the nozzle

Approximately 30° down, 45° toward the rear, and aimed

at the corner of the windshield

Approximately 30° down, 45° toward the rear, and aimed

at the center of the rear door

Approximately 30° down, 30° toward the front and aimed

approximately 610 mm (24.0 in.) from the corner of the

back window