Skoda Yeti (2017 year). Manual - part 10

The speed limit for all-season or “winter”Tires can be adjusted in MAXI

DOTDisplay in the menu item winter tires

.

If the vehicle has all-season or “winter”tires of a lower speed category then

the specified maximum speed of the vehicle (referring to tyres that have not

been delivered by the factory, a warning label with the maximum value of the

speed category provided for the mounted tyres must be fixed in the interior of

the vehicle in a constantly visible place in the driver’s field of vision. The warn-

ing label (sticker) can be replaced by setting maximum value of the mounted

tire speed rating in the MAXI DOTDisplay in thewinter tiresmenu item

specification defines the maximum vehicle speed with mounted all-season or

“winter”tyres that may not be exceeded.

Snow chains

The snow chains improve handling in wintry road conditions.

Remove the full wheel trims before installing the snow chains

.

Only fit snow chains with links and locks not larger than 12 mm.

The use of snow chains on vehicles with front-wheel drive and on vehicles

with four-wheel drive differs.

Front-wheel drive

Snow chains must only be fitted on the front wheels and are applicable only to

the following wheel / tyre combinations.

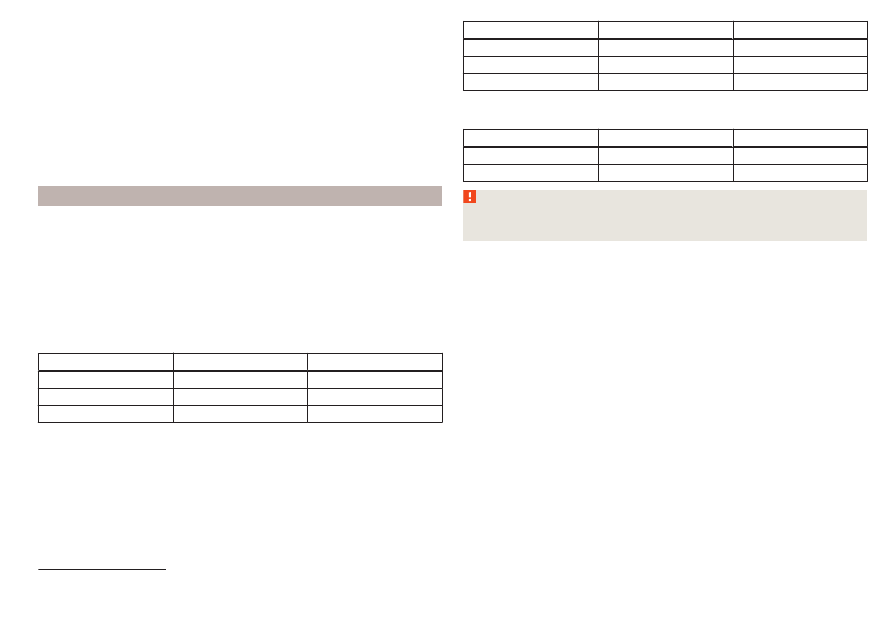

Rim size

Press depth D

Tyre size

6J x 16

50 mm

205/55 R16

7J x 16

45 mm

205/55 R16

6J x 17

45 mm

205/50 R17

All-wheel drive

Snow chains can be mounted on the wheels on the front and rear axles.

It is only permissible to fit snow chains on the front wheels with the following

wheel/tyre combinations.

Rim size

Press depth D

Tyre size

6J x 16

50 mm

205/55 R16

7J x 16

45 mm

205/55 R16

6J x 17

45 mm

205/50 R17

It is only permissible to fit snow chains on the rear wheels with the following

wheel/tyre combinations.

Rim size

Press depth D

Tyre size

7J x 16

45 mm

215/60 R16

7J x 17

45 mm

225/50 R17

WARNING

Do not use chains on snow and ice-free routes - the handling would be im-

paired and there is a risk of damage to the tyres.

1)

Valid in certain countries.

153

Wheels