Renault Master (2018 year). Instruction - part 16

5.34

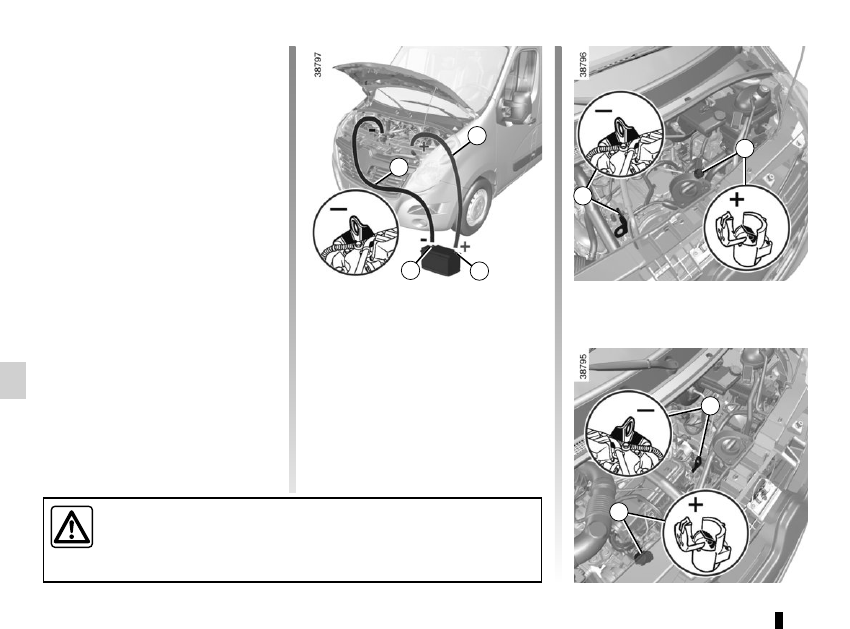

BATTERY: troubleshooting

(2/2)

Attach the positive lead (+) A to termi-

nal 3, then to terminal 2 (+) of the bat-

tery supplying the current.

Attach negative lead (–) B to terminal 1

(–) of the battery supplying the current,

then to earth 4 (–).

Start the engine as normal. As soon as

it is running, disconnect leads A and B

in the reverse order (4-3-2-1).

Starting the vehicle using the

battery from another vehicle

If you have to use the battery from an-

other vehicle to start, obtain suitable

jump leads (with a large cross section)

from an approved dealer or, if you al-

ready have jump leads, ensure that

they are in perfect condition.

The two batteries must have an iden-

tical nominal voltage of 12 volts. The

battery supplying the current should

have a capacity (amp-hours, Ah) which

is at least the same as that of the dis-

charged battery.

Ensure that there is no risk of contact

between the two vehicles (risk of short

circuiting when the positive terminals

are connected). Switch off your vehicle

ignition.

Start the engine of the vehicle supply-

ing the current and run it at a moderate

speed.

A

B

2

1

Check that there is no contact between leads A and B and that the posi-

tive lead A is not touching any metal parts on the vehicle supplying the

current.

Risk of injury and/or damage to the vehicle.

3

4

4

3