Chrysler Cirrus, Dodge Stratus, Plymouth Breeze Haynes. Manual - part 29

10-4

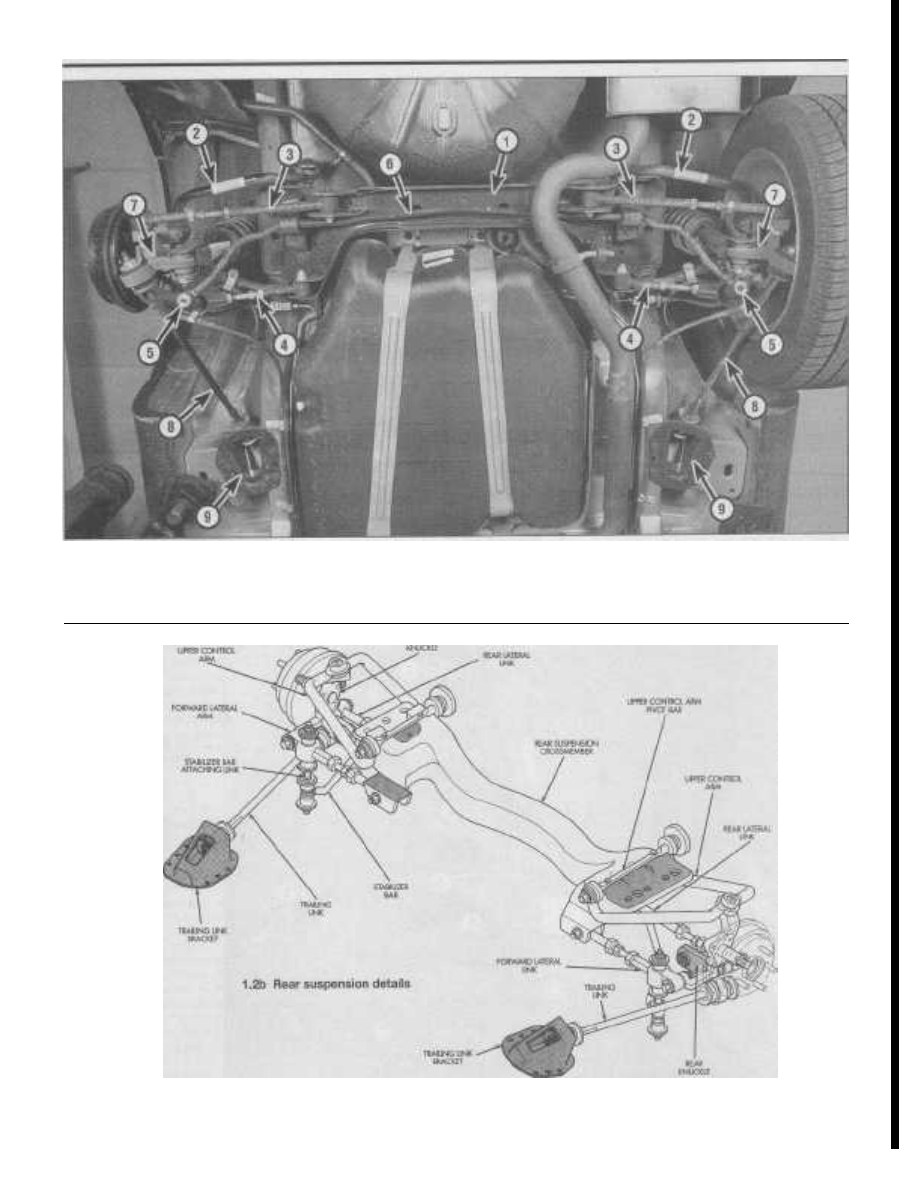

Chapter 10 Suspension and steering systems

1.2a Rear suspension components

1

Crossmember

4

Forward lateral link

7

Rear knuckle

2

Upper control arm

5

Stabilizer bar attaching link

8

Trailing link

3

Rear lateral link

6

Stabilizer bar

9

Trailing link bracket