Chrysler Cirrus, Dodge Stratus, Plymouth Breeze Haynes. Manual - part 24

7A-4

Chapter 7 Part A Manual transaxle

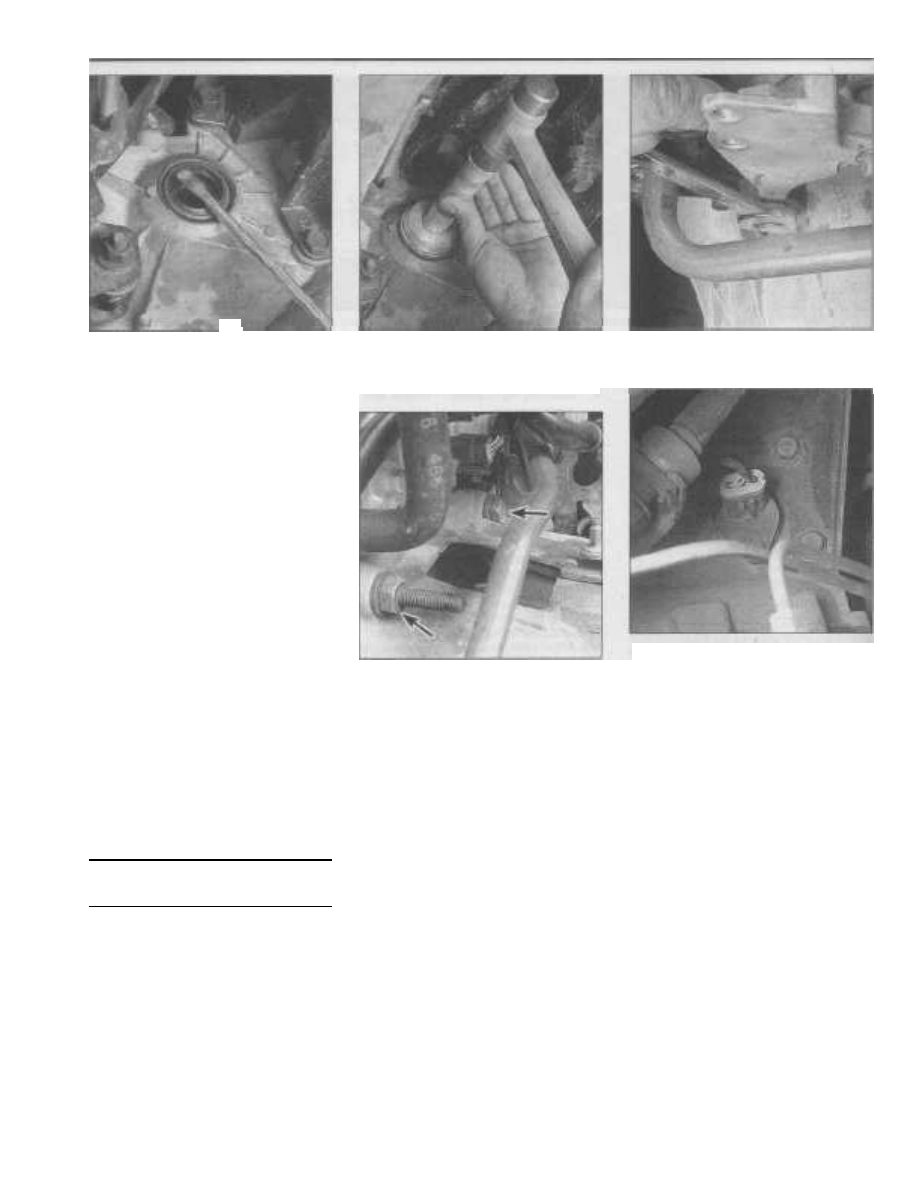

5.6 Using a seal driver, large section of

pipe or a large deep socket as a drift,

drive the new seal squarely into the bore

and make sure that it's completely seated

6.8 Remove the intake manifold

support bracket

6.9 Remove the upper clutch housing

fasteners (arrows)

6.10 The Vehicle Speed Sensor is located

on the transaxle next to the rear

engine mount

5.4 Using a large screwdriver or prybar,

carefully pry the oil seal out of the

transaxle (if you can't remove the oil seal

with a screwdriver or prybar, you may

need to obtain a special seal removal tool,

available at most auto parts stores, to do

the job)

inner ends of the driveaxles mate with the dif-

ferential side gears. If you suspect that one of

these seals is leaking, raise the vehicle and

support it securely on jackstands. If a seal is

in fact leaking, you'll see a trail of wet lubri-

cant on the side of the transaxle below the

seal.

3

Remove the driveaxle (see Chapter 8).

4

Using a large screwdriver or prybar,

carefully pry the oil seal out of the transaxle

(see illustration).

5

If you can't remove the oil seal with a

screwdriver or pry bar, you may need to

obtain a special seal removal tool (available

at most auto parts stores) to do the job.

6

Using a seal driver, large section of pipe

or a large deep socket as a drift, install the

new oil seal (see illustration). Drive it into the

bore squarely and make sure that it's com-

pletely seated. Lubricate the driveaxle oil

seal, tripod joint splines and sealing surface

with the appropriate transmission fluid (see

Chapter 1).

7

Install the driveaxle (see Chapter 8). Be

careful not to damage the lip of the new seal

during installation.

6

Manual transaxle - removal and

installation

Note 1: This procedure requires the removal

of all engine mounts except for the right side

engine mount. If the vehicle must be moved

after the transaxle has been removed, make

sure the engine is supported at all times and

the appropriate sized bolts and nuts are

installed in the front wheel hub/bearings (refer

to Chapter 8).

Note 2: There are four different gear ratios

available with this transaxle. If you are going

to replace this transaxle or obtain a rebuilt

unit, check the metal identification tag

mounted to the rear cover before purchasing

a new or rebuilt transaxle to ensure you're

getting the correct gear ratio for your particu-

lar application.

Removal

Refer to illustrations 6.8, 6.9, 6.10, 6.16, 6.17,

6.18, 6.19, 6.28 and 6.31

1

Open the hood and place protective

covers on the front fenders and cowl. Special

fender covers are available, but an old bed-

spread or blankets will also work.

2

Disconnect the negative battery cable

from the ground stud on the left shock tower

(see Chapter 5, Section 1).

3

Remove the air cleaner assembly (see

Chapter 4).

4

Disconnect the clutch cable from the

release lever (see Chapter 8).

5

Disconnect the shift cables from the

transaxle and detach the cable bracket (with

cables attached) from the transaxle (see Sec-

tion 2). Position the cables out of the way.

6

Detach the accelerator cable and cruise

control cable (if equipped) from the throttle

lever (see Chapter 4 if necessary).

7

Detach the accelerator/cruise control

cable bracket from the throttle body (with

cables attached) and position it out of the

way.

8

Remove the intake manifold support

bracket (see illustration).

9

Remove the upper clutch housing bolts

(see illustration).

10

Disconnect the electrical connectors

from the vehicle speed sensor (see illustra-

tion) and back-up light switch (see illustra-

tion 4.1).

11

Loosen the driveaxle hub nuts (see

Chapter 8) and front wheel lug nuts. Raise the

vehicle and place it securely on jackstands.

Remove both front wheels.

12

Drain the transaxle fluid (see Chapter 1).

13

Remove the driveaxles (see Chapter 8).

14

Remove the starter motor (see Chap-

ter 5).

15

Remove the splash shield/battery cover

from the left front wheel well (see Chapter 5).

Extract the push-in fasteners and remove the

transaxle splash shield.

16

On 1998 models, remove the oil pan-to-