Peugeot 205 (954 cc, 1124 cc, 1360 cc, 1580 cc & 1905 cc). Manual - part 28

Buying spare parts

Spare parts are available from many

sources, including maker’s appointed

garages, accessory shops, and motor factors.

To be sure of obtaining the correct parts, it

will sometimes be necessary to quote the

vehicle identification number. If possible, it

can also be useful to take the old parts along

for positive identification. Items such as

starter motors and alternators may be

available under a service exchange scheme -

any parts returned should always be clean.

Our advice regarding spare part sources is

as follows.

Officially-appointed garages

This is the best source of parts which are

peculiar to your car, and which are not

otherwise generally available (eg badges,

interior trim, certain body panels, etc). It is

also the only place at which you should buy

parts if the vehicle is still under warranty.

Accessory shops

These are very good places to buy

materials and components needed for the

maintenance of your car (oil, air and fuel

filters, spark plugs, light bulbs, drivebelts, oils

and greases, brake pads, touch-up paint, etc).

Components of this nature sold by a

reputable shop are of the same standard as

those used by the car manufacturer.

Besides components, these shops also sell

tools and general accessories, usually have

convenient opening hours, charge lower

prices, and can often be found not far from

home. Some accessory shops have parts

counters where the components needed for

almost any repair job can be purchased or

ordered.

Motor factors

Good factors will stock all the more

important components which wear out

comparatively quickly, and can sometimes

supply individual components needed for the

overhaul of a larger assembly (eg brake seals

and hydraulic parts, bearing shells, pistons,

valves, alternator brushes). They may also

handle work such as cylinder block reboring,

crankshaft regrinding and balancing, etc.

Tyre and exhaust specialists

These outlets may be independent, or

members of a local or national chain. They

frequently offer competitive prices when

compared with a main dealer or local garage,

but it will pay to obtain several quotes before

making a decision. When researching prices,

also ask what “extras” may be added - for

instance, fitting a new valve and balancing the

wheel are both commonly charged on top of

the price of a new tyre.

Other sources

Beware of parts or materials obtained from

market stalls, car boot sales or similar outlets.

Such items are not invariably sub-standard,

but there is little chance of compensation if

they do prove unsatisfactory. In the case of

safety-critical components such as brake

pads, there is the risk not only of financial loss

but also of an accident causing injury or

death.

Second-hand components or assemblies

obtained from a car breaker can be a good

buy in some circumstances, but this sort of

purchase is best made by the experienced

DIY mechanic.

Modifications are a continuing and

unpublicised process in vehicle manufacture.

Spare parts manuals and lists are compiled on

a numerical basis, the individual vehicle

numbers being essential to identify correctly

the component required.

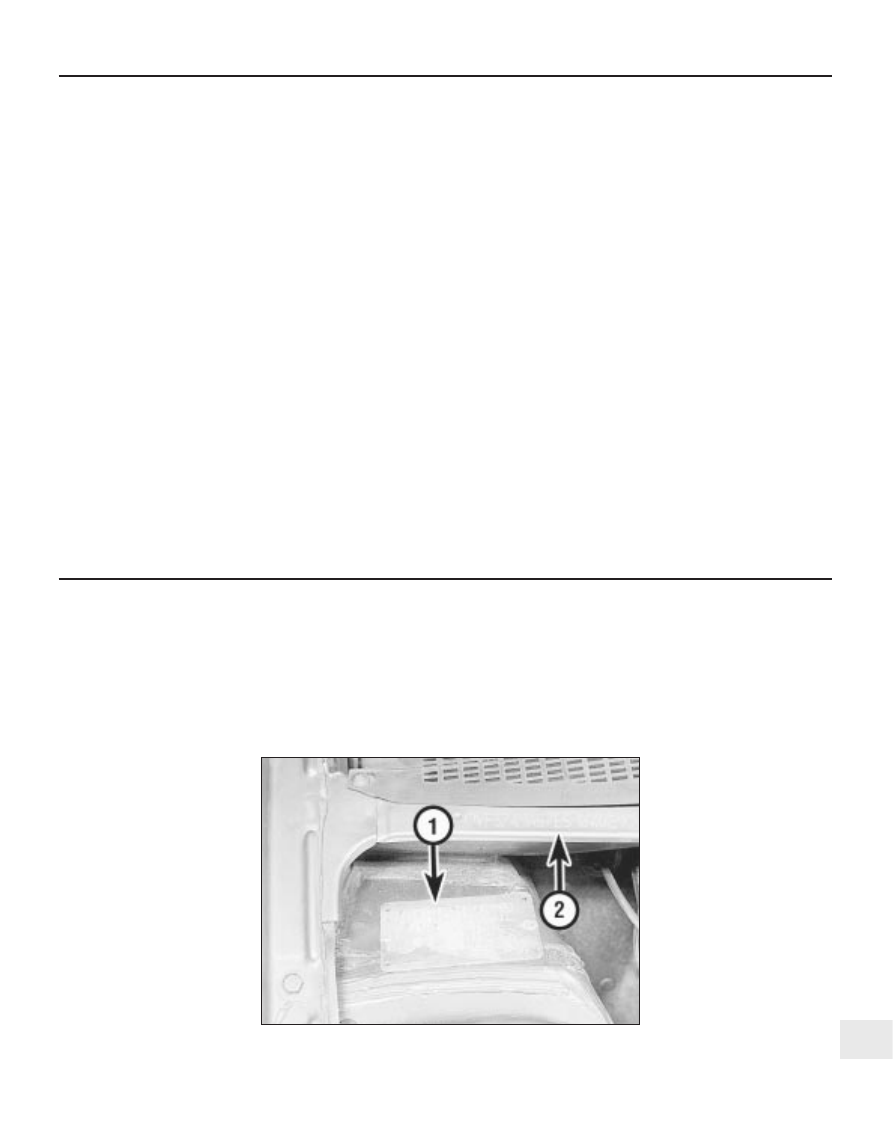

The vehicle identification plate is located on

the right-hand front wing valance in the

engine compartment (see illustration).

The body serial number is stamped on the

scuttle crossmember above the vehicle

identification plate.

The engine number is situated on the

cylinder block. On non-XU engine models

with an aluminium cylinder block, the number

is stamped on a plate which is riveted to the

flywheel end of the block; on later models with

a cast-iron block, the number is stamped on a

machined surface on the flywheel end of the

block. On early XU engine models, the

number is stamped on a plate which is riveted

to the timing belt end of the front of the

cylinder block; on later models, the number is

stamped on a machined surface at the

flywheel end of the front of the block.

Buying spare parts

REF•3

REF

Vehicle identification

Vehicle identification plate (1) and body serial number (2)