Peugeot 205 (954 cc, 1124 cc, 1360 cc, 1580 cc & 1905 cc). Manual - part 22

7 If necessary, the intermediate shaft can be

removed after prising out the grommet and

unscrewing the bottom clamp bolt (see

illustration).

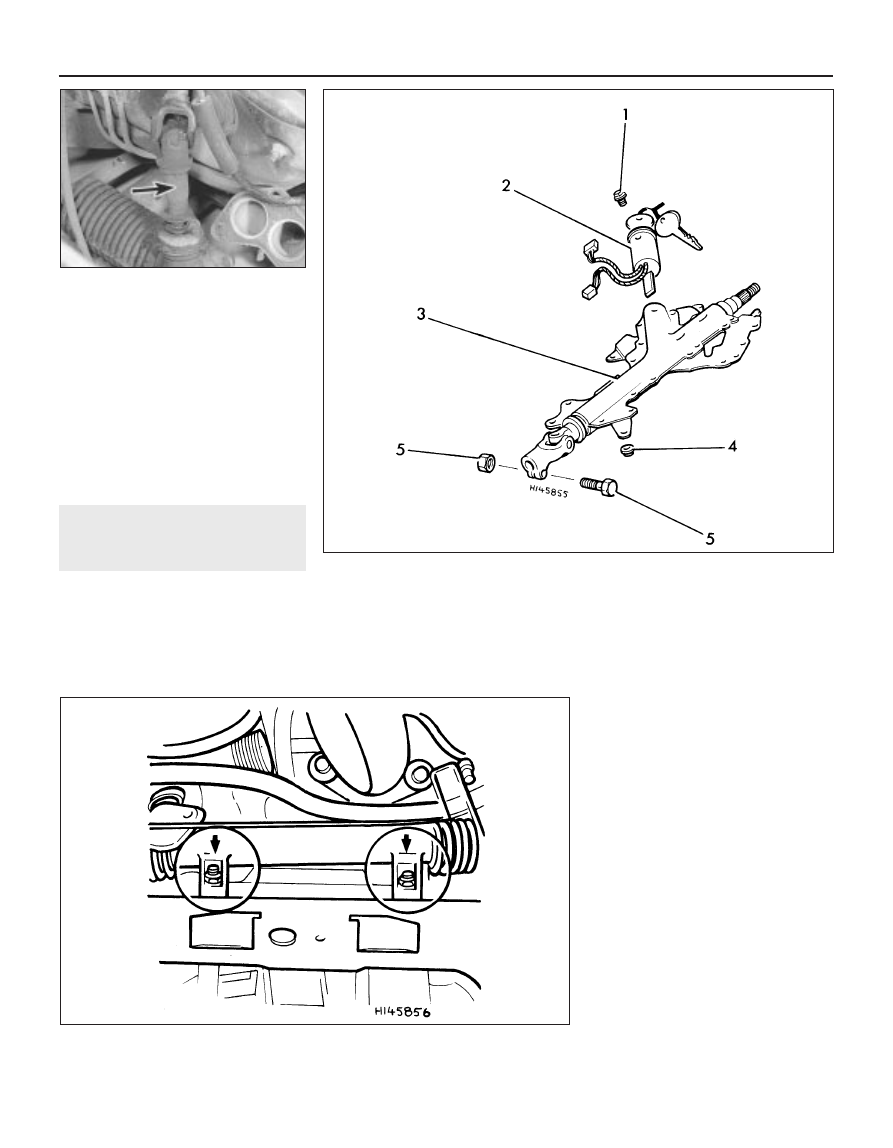

8 To remove the steering lock, unscrew the

retaining bolt then, with the ignition key

aligned with the small arrow between the ‘A’

and ‘M’ positions, depress the plunger in the

housing and withdraw the lock (see

illustration).

Refitting

9 Refitting is a reversal of removal.

15 Steering gear - removal and

refitting

4

Manual steering gear

Removal

1 Chock the rear wheels then jack up the

front of the car and support it on axle stands

(see “Jacking and vehicle support”). Remove

the front roadwheels.

2 Unscrew the track rod end locknuts then

use a separator tool to detach the track rod

end balljoints from the hub carrier steering

arms.

3 Mark the lower column in relation to the

pinion on the steering gear.

4 Unscrew and remove the column-to-pinion

clamp bolt.

5 Unscrew and remove the two mounting

bolts and withdraw the steering gear from one

side of the subframe (see illustration).

Refitting

6 Refitting is a reversal of removal, but tighten

all nuts and bolts to the specified torque. On

completion, have the front wheel toe setting

checked (see Section 21).

Power-assisted steering gear

Removal

7 Chock the rear wheels then jack up the

front of the car and support it on axle stands

(see “Jacking and vehicle support”). Remove

the front roadwheels.

8 Prepare a suitable container, then

disconnect the fluid pipes from the steering

gear, and allow the fluid to drain into the

container.

9 Unscrew the track rod end balljoint

locknuts, then use a separator tool to detach

the track rod end balljoints from the hub

carrier steering arms.

10 Mark the lower column in relation to the

pinion on the steering gear.

11 Unscrew and remove the

column-to-pinion clamp bolt.

12 On manual transmission models,

disconnect the three gearchange control rods

from the levers on the transmission.

13 Extract the spring clip from the

gearchange linkage (see illustration), then

unclip the transmission selector and

10•8 Suspension and steering

14.7 Steering column intermediate shaft

(arrowed)

14.8 Steering column and lock assembly

components

1 Bolt

2 Steering lock and ignition

switch

3 Steering column

4 Mounting nut

5 Clamp bolt and nut

15.5 Steering gear mounting bolt locations (arrowed)