Peugeot 405 Haynes (petrol). Manual - part 4

Maintenance procedures

1•8

6000 Mile / 6 Month Service

1

Introduction

General information

1 This Chapter is designed to help the home

mechanic maintain his/her vehicle for safety,

economy, long life and peak performance.

2 The Chapter contains a master

maintenance schedule, followed by Sections

dealing specifically with each task in the

schedule. Visual checks, adjustments,

component renewal and other helpful items

are included. Refer to the accompanying

illustrations of the engine compartment and

the underside of the vehicle for the locations

of the various components.

3 Servicing your vehicle in accordance with

the mileage/time maintenance schedule and

the following Sections will provide a planned

maintenance programme, which should result

in a long and reliable service life. This is a

comprehensive plan, so maintaining some

items but not others at the specified service

intervals, will not produce the same results.

4 As you service your vehicle, you will

discover that many of the procedures can -

and should - be grouped together, because of

the particular procedure being performed, or

because of the close proximity of two

otherwise-unrelated components to one

another. For example, if the vehicle is raised

for any reason, the exhaust can be inspected

at the same time as the suspension and

steering components.

5 The first step in this maintenance

programme is to prepare yourself before the

actual work begins. Read through all the

Sections relevant to the work to be carried

out, then make a list and gather together all

the parts and tools required. If a problem is

encountered, seek advice from a parts

specialist, or a dealer service department.

2

Intensive maintenance

1 If, from the time the vehicle is new, the

routine maintenance schedule is followed

closely, and frequent checks are made of fluid

levels and high-wear items, as suggested

throughout this manual, the engine will be

kept in relatively good running condition, and

the need for additional work will be minimised.

2 It is possible that there will be times when

the engine is running poorly due to the lack of

regular maintenance. This is even more likely

if a used vehicle, which has not received

regular and frequent maintenance checks, is

purchased. In such cases, additional work

may need to be carried out, outside of the

regular maintenance intervals.

3 If engine wear is suspected, a compression

test will provide valuable information

regarding the overall performance of the main

internal components. Such a test can be used

as a basis to decide on the extent of the work

to be carried out. If, for example, a

compression test indicates serious internal

engine wear, conventional maintenance as

described in this Chapter will not greatly

improve the performance of the engine, and

may prove a waste of time and money, unless

extensive overhaul work is carried out first.

4 The following series of operations are those

most often required to improve the

performance of a generally poor-running

engine:

Primary operations

a) Clean, inspect and test the battery (see

“Weekly checks”).

b) Check all the engine-related fluids (see

“Weekly checks”).

c) Check the condition and tension of the

auxiliary drivebelt (Section 5).

d) Renew the spark plugs (Section 11).

e) Inspect the distributor cap and HT leads -

as applicable (Section 22).

f) Check the condition of the air cleaner

filter element, and renew if necessary

(Section 21).

g) Renew the fuel filter (Section 8).

h) Check the condition of all hoses, and

check for fluid leaks (Section 6).

i) Check the idle speed and mixture settings

- as applicable (Section 10).

5 If the above operations do not prove fully

effective, carry out the following secondary

operations:

Secondary operations

a) Check the charging system (Chapter 5A).

b) Check the ignition system (Chapter 5B).

c) Check the fuel system (Chapter 4).

d) Renew the distributor cap and rotor arm -

as applicable (Chapter 5B).

e) Renew the ignition HT leads - as

applicable (Section 22).

6000 Mile / 6 Month Service

3

Engine oil and filter renewal

1

Note: On models from 1994, the maker’s

specified interval for this procedure is

9000 miles (15 000 km) or 12 months.

Note: A suitable square-section wrench may

be required to undo the sump drain plug on

some models. These wrenches cab be

obtained from most motor factors or your

Peugeot dealer.

1 Frequent oil and filter changes are the most

important preventative maintenance

procedures which can be undertaken by the

DIY owner. As engine oil ages, it becomes

diluted and contaminated, which leads to

premature engine wear.

2 Before starting this procedure, gather

together all the necessary tools and materials.

Also make sure that you have plenty of clean

rags and newspapers handy, to mop up any

spills. Ideally, the engine oil should be warm,

as it will drain better, and more built-up

sludge will be removed with it. Take care,

however, not to touch the exhaust or any

other hot parts of the engine when working

under the vehicle. To avoid any possibility of

scalding, and to protect yourself from

possible skin irritants and other harmful

contaminants in used engine oils, it is

advisable to wear gloves when carrying out

this work. Access to the underside of the

vehicle will be greatly improved if it can be

raised on a lift, driven onto ramps, or jacked

up and supported on axle stands (see

“Jacking and Vehicle Support”). Whichever

method is chosen, make sure that the vehicle

remains level, or if it is at an angle, so that the

drain plug is at the lowest point. Where

necessary remove the splash guard from

under the engine.

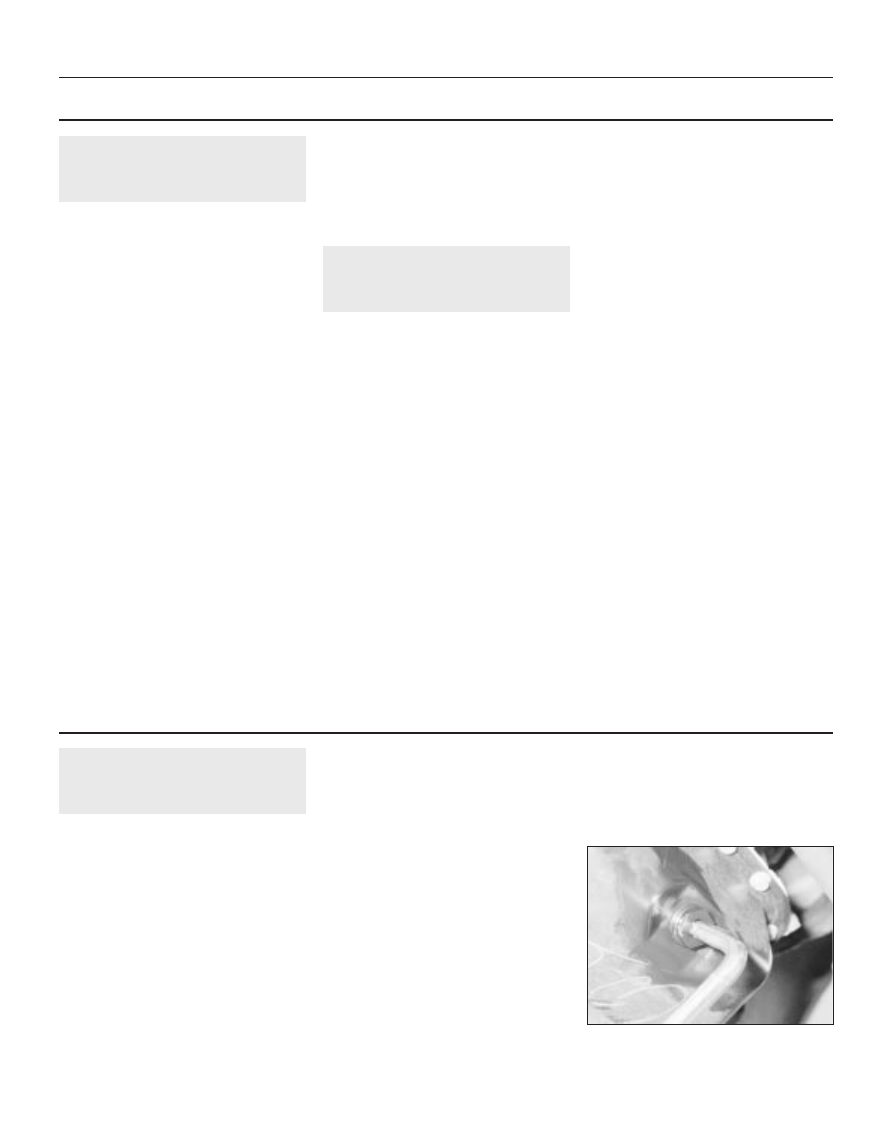

3 Slacken the drain plug about half a turn; on

some models, a square-section wrench may

be needed to slacken the plug (see

illustration). Position the draining container

under the drain plug, then remove the plug

completely. If possible, try to keep the plug

3.3 Slackening the sump drain plug with a

square-section wrench