содержание .. 22 23 24 25 ..

Peugeot 405. Manual - part 24

correct reassembly. Discard the circlips - new

ones must be used on refitting.

16 Examine the gudgeon pin and connecting

rod small-end bearing for signs of wear or

damage. Wear can be cured by renewing both

the pin and bush. Bush renewal, however, is a

specialist job - press facilities are required,

and the new bush must be reamed accurately.

17 The connecting rods themselves should

not be in need of renewal, unless seizure or

some other major mechanical failure has

occurred. Check the alignment of the

connecting rods visually, and if the rods are

not straight, take them to an engine overhaul

specialist for a more detailed check.

18 Examine all components, and obtain any

new parts from your Peugeot dealer. If new

pistons are purchased, they will be supplied

complete with gudgeon pins and circlips.

Circlips can also be purchased individually.

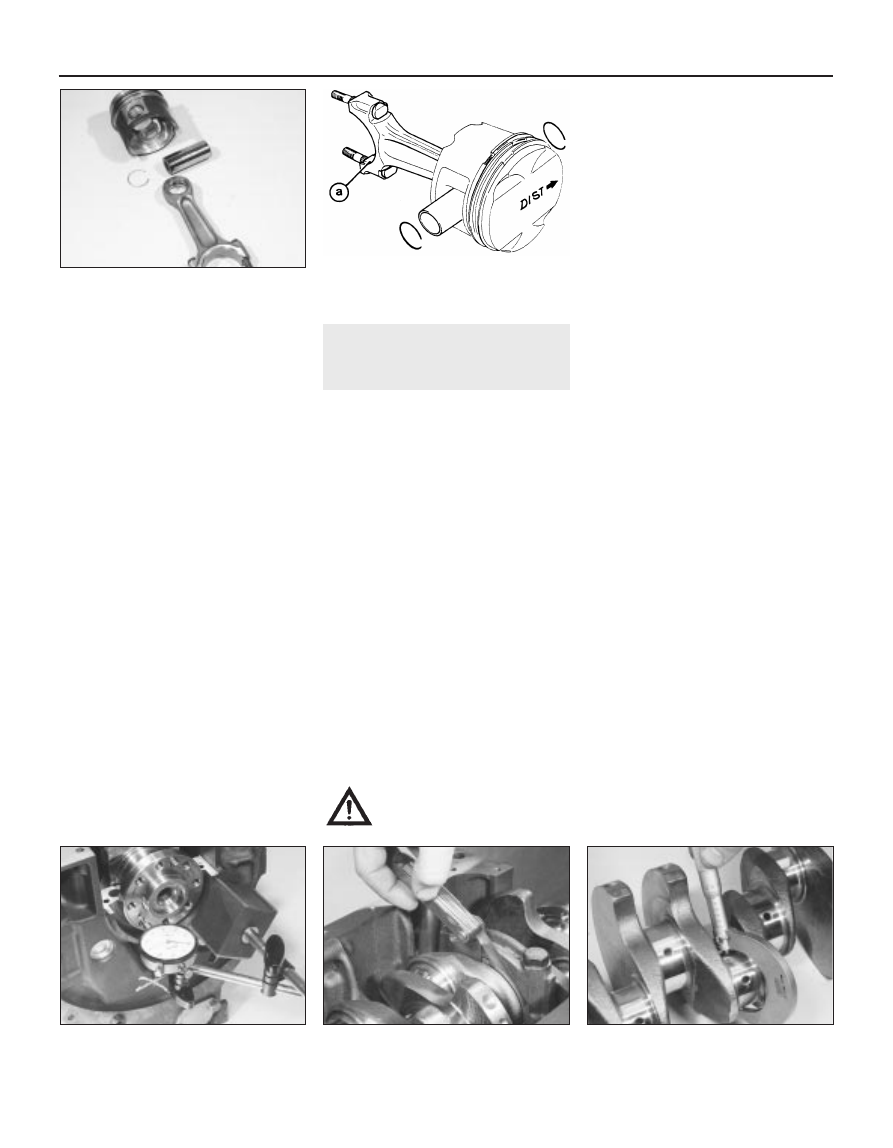

19 Position the piston so that the arrow on

the piston crown is positioned as shown in

relation to the connecting rod big-end bearing

shell cutouts (see illustration). Apply a smear

of clean engine oil to the gudgeon pin. Slide it

into the piston and through the connecting

rod small-end. Check that the piston pivots

freely on the rod, then secure the gudgeon pin

in position with two new circlips. Ensure that

each circlip is correctly located in its groove in

the piston.

14 Crankshaft - inspection

2

Checking crankshaft endfloat

1 If the crankshaft endfloat is to be checked,

this must be done when the crankshaft is still

installed in the cylinder block/crankcase, but

is free to move (see Section 11).

2 Check the endfloat using a dial gauge in

contact with the end of the crankshaft. Push

the crankshaft fully one way, and then zero

the gauge. Push the crankshaft fully the other

way, and check the endfloat. The result can

be compared with the specified amount, and

will give an indication as to whether new

thrustwashers are required (see illustration).

3 If a dial gauge is not available, feeler blades

can be used. First push the crankshaft fully

towards the flywheel/driveplate end of the

engine, then use feeler blades to measure the

gap between the web of No 2 crankpin and

the thrustwasher (see illustration).

Inspection

4 Clean the crankshaft using paraffin or a

suitable solvent, and dry it, preferably with

compressed air if available. Be sure to clean

the oil holes with a pipe cleaner or similar

probe, to ensure that they are not obstructed.

5 Check the main and big-end bearing

journals for uneven wear, scoring, pitting and

cracking.

6 Big-end bearing wear is accompanied by

distinct metallic knocking when the engine is

running (particularly noticeable when the

engine is pulling from low speed) and some

loss of oil pressure.

7 Main bearing wear is accompanied by

severe engine vibration and rumble - getting

progressively worse as engine speed

increases - and again by loss of oil pressure.

8 Check the bearing journal for roughness by

running a finger lightly over the bearing

surface. Any roughness (which will be

accompanied by obvious bearing wear)

indicates that the crankshaft requires

regrinding (where possible) or renewal.

9 If the crankshaft has been reground, check

for burrs around the crankshaft oil holes (the

holes are usually chamfered, so burrs should

not be a problem unless regrinding has been

carried out carelessly). Remove any burrs with

a fine file or scraper, and thoroughly clean the

oil holes as described previously.

10 Using a micrometer, measure the

diameter of the main and big-end bearing

journals, and compare the results with the

Specifications

(see illustration). By

measuring the diameter at a number of points

around each journal’s circumference, you will

be able to determine whether or not the

journal is out-of-round. Take the

measurement at each end of the journal, near

the webs, to determine if the journal is

tapered. Compare the results obtained with

those given in the Specifications. Where no

specified journal diameters are quoted, seek

the advice of a Peugeot dealer.

11 Check the oil seal contact surfaces at

each end of the crankshaft for wear and

damage. If the seal has worn a deep groove in

the surface of the crankshaft, consult an

engine overhaul specialist; repair may be

possible, but otherwise a new crankshaft will

be required.

12 At the time of writing, it was not clear

whether Peugeot produce oversize bearing

shells for all of these engines. On some

engines, if the crankshaft journals have not

already been reground, it may be possible to

have the crankshaft reconditioned, and to fit

14.10 Measuring a crankshaft big-end

journal diameter

2C•14 Engine removal and overhaul

13.15c Piston and connecting rod

components

14.3 Checking crankshaft endfloat

using feeler gauges

14.2 Checking crankshaft endfloat

using a dial gauge

13.19 On 16-valve engines, on refitting

ensure that the piston arrow is positioned

as shown, in relation to the connecting rod

bearing shell cutout (a)

Warning: Wear eye protection

when using compressed air!