содержание .. 17 18 19 20 ..

Peugeot 405. Manual - part 19

the clearance was less than that specified, the

thickness of the shim must be decreased by

the difference recorded (2).

18 Draw three more lines beneath each valve

on the calculation paper, as shown in

illustration 11.7. On line (4), note the

measured thickness of the shim, then add or

deduct the difference from line (2) to give the

final shim thickness required on line (5).

19 Shims are available in thicknesses

between 2.225 mm and 3.550 mm, in steps of

0.025 mm. Clean new shims before

measuring or fitting them.

20 Repeat the procedure given in paragraphs

16 to 18 on the remaining valves, keeping

each follower identified for position.

21 When reassembling, oil the shim, and fit it

on the valve stem with the size marking face

downwards. Oil the follower, and lower it onto

the shim. Do not raise the follower after fitting,

as the shim may become dislodged.

22 When all the followers are in position,

complete with their shims, refit the camshaft

as described in Section 10. Recheck the valve

clearances before refitting the cylinder head

cover.

12 Cylinder head -

removal and refitting

4

Removal

1 Remove the battery and its mounting tray

with reference to Chapter 5A.

2 Drain the cooling system as described in

Chapter 1.

3 Align the engine assembly/valve timing

holes as described in Section 3, locking both

the camshaft sprocket and crankshaft pulley

in position, and proceed as described under

the relevant sub-heading. Do not attempt to

rotate the engine whilst the pins are in

position.

8-valve engines

4 Remove the cylinder head cover as

described in Section 4, and remove the air

cleaner mounting bracket from the rear of

cylinder head.

5 Note that the following text assumes that

the cylinder head will be removed with both

inlet and exhaust manifolds attached; this is

easier, but makes it a bulky and heavy

assembly to handle. If it is wished first to

remove the manifolds, proceed as described

in Chapter 4.

6 Working as described in Chapter 4,

disconnect the exhaust system front pipe

from the manifold. Where necessary,

disconnect or release the lambda sensor

wiring, so that it is not strained by the weight

of the exhaust.

7 Disconnect the following according to

model, as described in Chapter 4:

a) On fuel injection models, depressurise the

fuel system, and disconnect the fuel feed

and return hoses. Plug all openings, to

prevent loss of fuel and the entry of dirt

into the system.

b) On carburettor models remove the

carburettor and disconnect the fuel hoses

from the fuel pump.

c) Disconnect the accelerator cable.

d) Disconnect the vacuum servo unit

vacuum hose, coolant hose and all the

other relevant vacuum/breather hoses,

from the inlet manifold and on fuel

injection models the throttle

body/housing.

e) Undo the retaining nut, and position the

oil filler neck clear of the inlet manifold.

f) On fuel injection models, disconnect the

three electrical connector plugs from the

throttle body.

g) On fuel injection models, disconnect the

wiring connectors from the throttle

potentiometer and the fuel injectors, and

free the wiring loom from the manifold.

h) Where necessary, remove the idle speed

auxiliary air valve.

8 Slacken the retaining clips, and disconnect

the coolant hoses from the thermostat

housing (on the left-hand end of the cylinder

head).

9 Depress the retaining clip(s), and

disconnect the wiring connector(s) from the

electrical switch(es) and/or sensor(s) which

are screwed into the thermostat housing, or

into the left-hand end of the cylinder head (as

appropriate).

10 Refer to Section 8 and disconnect the

timing belt from the camshaft sprocket; if

preferred, completely remove the timing belt.

11 Jack up the front of the car and support

on axle stands (see “Jacking and Vehicle

Support”).

12 Unscrew and remove the horizontal bolt

from the engine rear mounting link beneath

the rear of the engine.

13 Place a jack beneath the engine, with a

block of wood on the jack head. Raise the

jack until it is supporting the weight of the

engine.

14 Slacken and remove the three nuts

securing the engine/transmission right-hand

mounting bracket to the engine bracket.

Remove the single nut securing the bracket to

the mounting rubber, and lift off the bracket.

Undo the three bolts securing the engine

bracket to the end of the cylinder head/block,

and remove the bracket.

15 On models with a distributor, disconnect

the wiring connector from the ignition HT coil.

If the cylinder head is to be dismantled for

overhaul, remove the distributor as described

in the relevant Sections of Chapter 5.

Disconnect the HT leads from the spark plugs,

and remove the distributor cap and lead

assembly. If the cylinder numbers are not

already marked on the HT leads, number each

lead, to avoid the possibility of the leads being

incorrectly connected on refitting.

16 On models with a static (distributorless)

ignition system, disconnect the wiring

connector from the ignition HT coil. If the

cylinder head is to be dismantled for overhaul,

remove the ignition HT coil as described in

Chapter 5. Note that the HT leads should be

disconnected from the spark plugs instead of

the coil, and the coil and leads removed as an

assembly. If the cylinder numbers are not

already marked on the HT leads, number each

lead, to avoid the possibility of the leads being

incorrectly connected on refitting.

17 Working in the reverse of the tightening

sequence, progressively slacken the ten

cylinder head bolts by half a turn at a time,

until all bolts can be unscrewed by hand.

Remove the bolts along with their washers,

noting the correct location of the spacer fitted

to the front left-hand bolt.

18 With all the cylinder head bolts removed,

the joint between the cylinder head and

gasket and the cylinder block/crankcase must

now be broken without disturbing the wet

liners. Care must be taken on 1508 cc, 1761

cc and 1905 cc engines to prevent

displacement of the wet liners; although these

liners are better-located and sealed than

some wet-liner engines, there is still a risk of

coolant and foreign matter leaking into the

sump if the cylinder head is lifted carelessly. If

care is not taken and the liners are moved,

there is also a possibility of the bottom seals

being disturbed, causing leakage after

refitting the head. This problem does not

apply to 1998 cc engines as the liners are

conventional and form part of the cylinder

block.

19 To break the joint, obtain two L-shaped

metal bars which fit into the cylinder head bolt

2B•18 XU engine in-car repair procedures

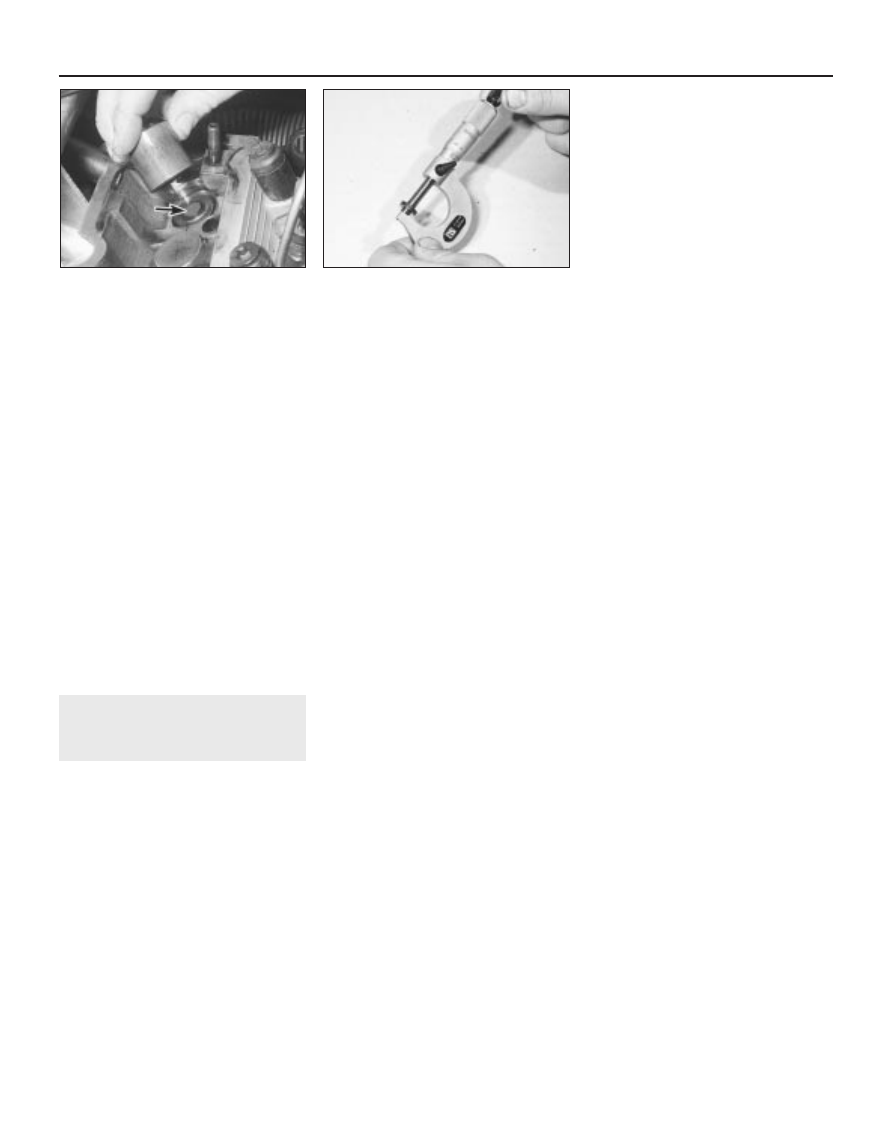

11.16a Lift out the follower and remove

the shim (arrowed)

11.16b Using a micrometer to measure

shim thickness