содержание .. 5 6 7 8 ..

Peugeot 405. Manual - part 7

Maintenance & Servicing

1•7

1

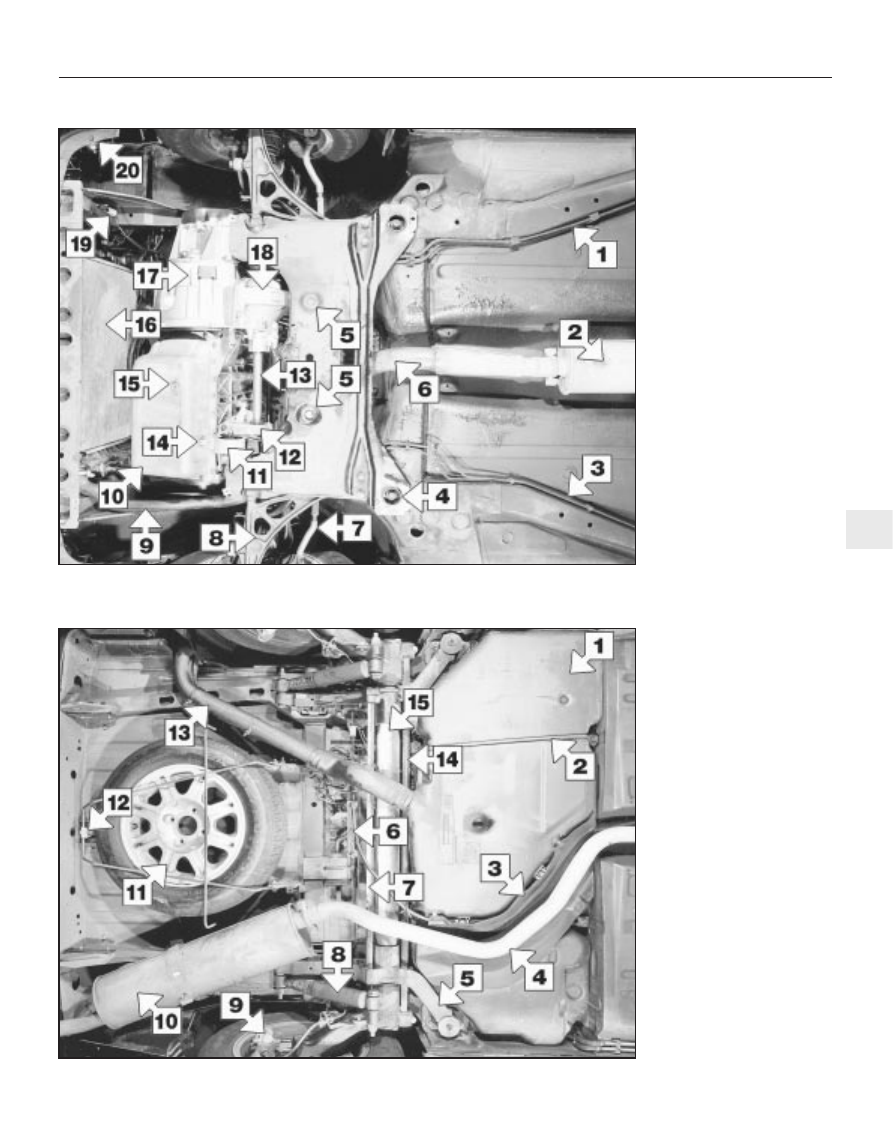

Rear underbody view of a 1905 cc engine model

1 Fuel tank

2 Fuel tank supporting strap

3 Heat shield

4 Exhaust pipe

5 Rear suspension side member

6 Handbrake cable equaliser

mechanism

7 Rear suspension torsion bar

8 Rear shock absorber

9 Rear disc brake caliper

10 Exhaust rear silencer

11 Spare wheel (cover removed)

12 Spare wheel cradle support

hook

13 Fuel filler hose

14 Rear anti-roll bar

15 Suspension cross-link

Front underbody view of a 1905 cc engine model

1 Fuel lines

2 Front exhaust silencer

3 Brake lines

4 Front subframe rear mounting

5 Steering rack mountings

6 Exhaust downpipe

7 Steering tack rod

8 Lower suspension arm

9 Radiator lower hose

10 Engine oil sump

11 Rear engine mounting

12 Driveshaft intermediate

bearing housing

13 Right-hand driveshaft

14 Oil temperature sensor

15 Engine oil drain plug

16 Radiator

17 Transmission housing

18 Differential housing

19 Cooling fan resistor

20 Horn