содержание .. 36 37 38 39 ..

Peugeot 205. Manual - part 38

3 If the hub nut has yet to be loosened,

fabricate a tool from two lengths of steel strip

(one long, one short) and a nut and bolt; the

nut and bolt form the pivot of a forked tool.

Bolt the tool to the hub flange using two wheel

bolts, and hold the tool to prevent the hub

from rotating (see Chapter 8, Section 2).

Slacken the hub nut using a socket and a long

extension bar.

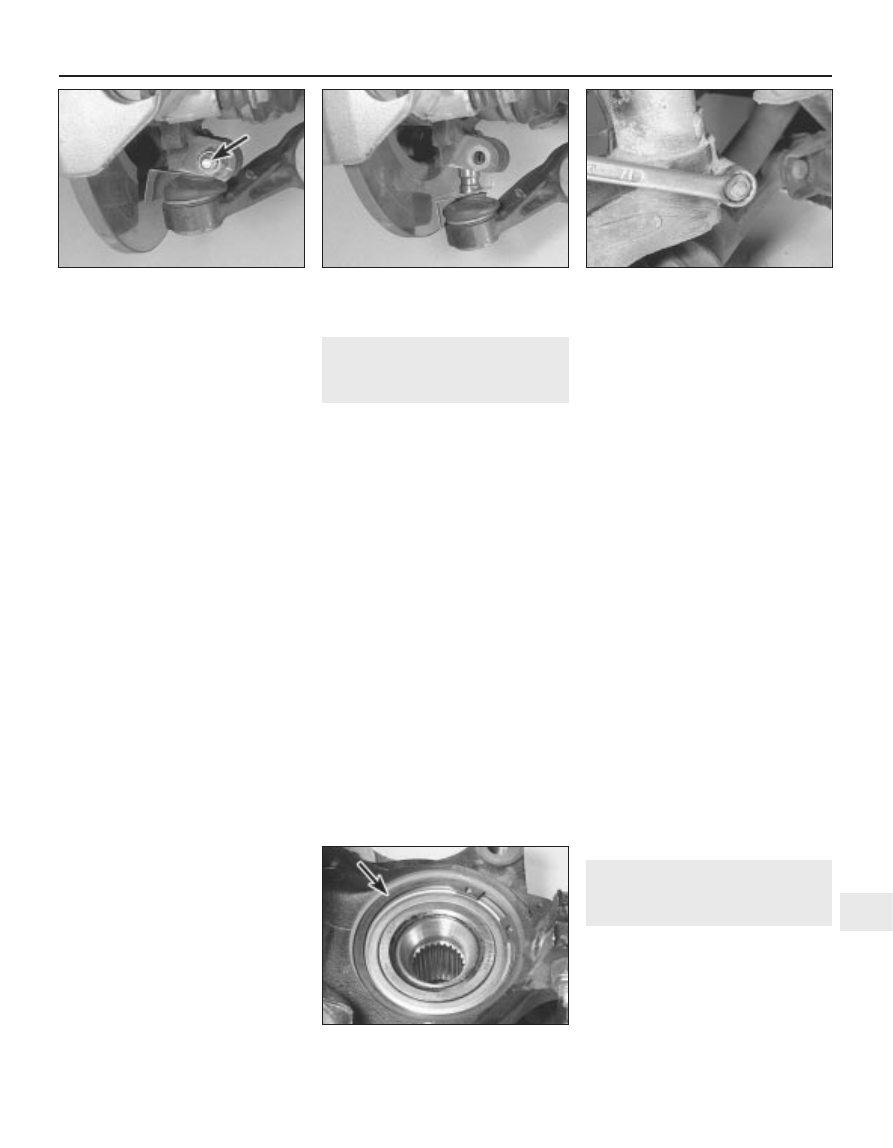

4 Unscrew the clamp bolt securing the front

suspension lower balljoint to the bottom of the

hub carrier then pull the lower suspension arm

down from the carrier (see illustrations).

5 Recover the balljoint guard plate, where

fitted.

6 Turn the front wheels to full right-hand lock

(left-hand hub carrier), or full left-hand lock

(right-hand hub carrier) and remove the hub

nut and, where fitted, the washer. Note that a

new hub nut will be required for refitting.

7 Pull the hub carrier outwards and at the

same time withdraw the outer end of the

driveshaft from the hub. Suitably support or

tie up the driveshaft in a near horizontal

position to avoid damage to the inner CV

joints.

8 Unbolt the disc brake caliper from the hub

carrier and either place it on a stand or tie it to

one side.

9 Remove the two screws and withdraw the

brake disc.

10 Unscrew the nut and use a balljoint

removal tool to separate the track rod end

balljoint from the hub carrier steering arm.

11 Unscrew the clamp bolt securing the

lower end of the suspension strut to the hub

carrier (see illustration). Spread the slot on

the hub carrier using a screwdriver or suitable

wedge and slide the carrier from the bottom

of the strut. Remove the hub carrier from the

car.

Refitting

12 Refitting is a reversal of removal, but refer

to Chapters 8 and 9 respectively when

refitting the driveshaft and disc brake caliper.

3

Front hub bearings - renewal

4

Note: The bearing is a sealed, pre-adjusted

and pre-lubricated, double-row ball type, and

is intended to last the car’s entire service life

without maintenance or attention. Never

overtighten the driveshaft nut beyond the

specified torque wrench setting in an attempt

to “adjust” the bearing.

Note: A press will be required to dismantle

and rebuild the assembly; if such a tool is not

available, a large bench vice and spacers

(such as large sockets) will serve as an

adequate substitute. The bearing’s inner races

are an interference fit on the hub; if the inner

race remains on the hub when it is pressed

out of the hub carrier, a knife-edged bearing

puller will be required to remove it. A new

bearing retaining circlip must be used on

refitting.

1 Remove the hub carrier assembly as

described in Section 2.

2 Support the hub carrier securely on blocks

or in a vice. Using a tubular spacer which

bears only on the inner end of the hub flange,

press the hub flange out of the bearing. If the

bearing’s outboard inner race remains on the

hub, remove it using a bearing puller (see note

above).

3 Extract the bearing retaining circlip from the

inner end of the hub carrier assembly (see

illustration).

4 Where necessary, refit the inner race back

in position over the ball cage, and securely

support the inner face of the hub carrier.

Using a tubular spacer which bears only on

the inner race, press the complete bearing

assembly out of the hub carrier.

5 Thoroughly clean the hub and hub carrier,

removing all traces of dirt and grease, and

polish away any burrs or raised edges which

might hinder reassembly. Check both for

cracks or any other signs of wear or damage,

and renew them if necessary. Renew the

circlip, regardless of its apparent condition.

6 On reassembly, apply a light film of oil to

the bearing outer race and hub flange shaft, to

aid installation of the bearing.

7 Securely support the hub carrier, and locate

the bearing in the hub. Press the bearing fully

into position, ensuring that it enters the hub

squarely, using a tubular spacer which bears

only on the bearing outer race.

8 Once the bearing is correctly seated,

secure the bearing in position with the new

circlip, ensuring that it is correctly located in

the groove in the hub carrier.

9 Securely support the outer face of the hub

flange, and locate the hub carrier bearing

inner race over the end of the hub flange.

Press the bearing onto the hub, using a

tubular spacer which bears only on the inner

race of the hub bearing, until it seats against

the hub shoulder. Check that the hub flange

rotates freely, and wipe off any excess oil or

grease.

10 Refit the hub carrier assembly as

described in Section 2.

4

Front suspension strut -

removal and refitting

4

Removal

1 Before raising the car it is recommended

that a retaining tool is fitted to the coil spring

to hold the spring in a semi-compressed

state. This will provide sufficient clearance to

enable the strut to be withdrawn from the hub

carrier. Peugeot garages use two special

cables inserted through the holes at the top of

Suspension and steering 10•3

10

2.4a Unscrew the lower balljoint clamp

bolt . . .

2.4b . . . and pull the suspension arm down

from the hub carrier

2.11 Unscrew the clamp bolt securing the

lower end of the suspension strut to the

hub carrier

3.3 Front hub bearing retaining circlip

(arrowed)