содержание .. 28 29 30 31 ..

Peugeot 205. Manual - part 30

4

Air inlet heating system

components - removal and

refitting

2

Note: The components of the system vary

slightly according to engine type. The

following procedures depict one of the more

common systems, but all are similar.

Vacuum switch

Removal

1 Remove the air cleaner housing-to-

carburettor inlet duct.

2 Bend up the tangs on the switch retaining

clip, then remove the clip, along with its seal,

and withdraw the switch from inside the duct.

Examine the seal for signs of damage or

deterioration, and renew if necessary.

Refitting

3 On refitting, ensure that the switch and duct

mating surfaces are clean and dry, and

position the switch inside the duct.

4 Fit the seal over the switch unions, and refit

the retaining clip. Ensure that the switch is

pressed firmly against the duct, and secure it

in position by bending down the retaining clip

tangs. Refit the duct.

Air temperature control valve

Removal

5 Disconnect the vacuum pipe from the air

temperature control valve, then slacken the

retaining clips securing the inlet ducts to the

valve.

6 Disconnect both inlet ducts and the hot-air

inlet hose from the control valve assembly,

and remove it from the vehicle.

Refitting

7 Refitting is the reverse of the removal

procedure, noting that the air temperature

control valve assembly can only be renewed

as a complete unit.

5

Crankcase ventilation

system components -

removal and refitting

2

The crankcase ventilation system consists

simply of a number of ventilation hoses, and a

wire mesh filter in the engine oil filler cap on

certain models. Removal and refitting is self-

explanatory, but it may be necessary to

detach surrounding components for improved

access. Refer to the various Chapters of this

manual as necessary if problems are

encountered.

6

Electro-pneumatic ignition

retarding system components

- removal and refitting

2

Solenoid valve

Removal

1 The valve is located on a bracket at the rear

of the engine compartment. To remove the

valve, proceed as follows.

2 Disconnect the battery negative lead, then

disconnect the wiring plug from the valve (see

illustration).

3 Note the orientation of the valve, then

disconnect the hoses from the valve, and pull

the valve from its bracket.

Refitting

4 Refitting is a reversal of removal, ensuring

that the valve is correctly orientated, as noted

before removal.

Coolant temperature sensor

Removal

5 The sensor is located in the left-hand end of

the cylinder head, below the engine coolant

temperature sensor for the fuel injection

system.

6 To remove the sensor, partially drain the

cooling system (see Chapter 1), then

disconnect the wiring, and unscrew and

remove the sensor.

Refitting

7 When refitting the sensor, ensure that the

seal is in good condition, and take care not to

overtighten the switch. Refill the cooling

system on completion as described in

Chapter 1 and “Weekly checks”.

7

Catalytic converter - general

information and precautions

The catalytic converter is a reliable and

simple device, which needs no maintenance

in itself, but there are some facts of which an

owner should be aware if the converter is to

function properly for its full service life.

a) DO NOT use leaded petrol in a vehicle

equipped with a catalytic converter - the

lead will coat the precious metals,

reducing their converting efficiency, and

will eventually destroy the converter.

b) Always keep the ignition and fuel systems

well-maintained in accordance with the

manufacturer’s schedule (see Chapter 1).

c) If the engine develops a misfire, do not

drive the vehicle at all (or at least as little

as possible) until the fault is cured.

d) DO NOT push - or tow-start the vehicle -

this will soak the catalytic converter in

unburned fuel, causing it to overheat

when the engine does start.

e) DO NOT switch off the ignition at high

engine speeds, ie do not “blip” the

throttle immediately before switching off.

f) DO NOT use fuel or engine oil additives -

these may contain substances harmful to

the catalytic converter.

g) DO NOT continue to use the vehicle if the

engine burns oil to the extent of leaving a

visible trail of blue smoke.

h) Remember that the catalytic converter

operates at very high temperatures. DO

NOT, therefore, park the vehicle in dry

undergrowth, over long grass or piles of

dead leaves, after a long run.

I) Remember that the catalytic converter is

FRAGILE. Do not strike it with tools

during servicing work.

j) In some cases, a sulphurous smell (like

that of rotten eggs) may be noticed from

the exhaust. This is common to many

catalytic converter-equipped vehicles.

Once the vehicle has covered a few

thousand miles, the problem should

disappear - in the meantime, try changing

the brand of petrol used.

k) The catalytic converter used on a well-

maintained and well-driven vehicle should

last for between 50 000 and 100 000

miles. If the converter is no longer

effective, it must be renewed.

8

Fuel vapour recirculation

system components -

removal and refitting

2

Carbon canister

Removal

1 The carbon canister is located at the rear

left-hand corner of the engine compartment

(see illustration).

2 To remove the canister, first disconnect the

hoses, noting their locations to ensure correct

refitting.

Exhaust and emission control systems 4D•5

4D

6.2 Disconnecting wiring plug from

ignition retarding system solenoid valve

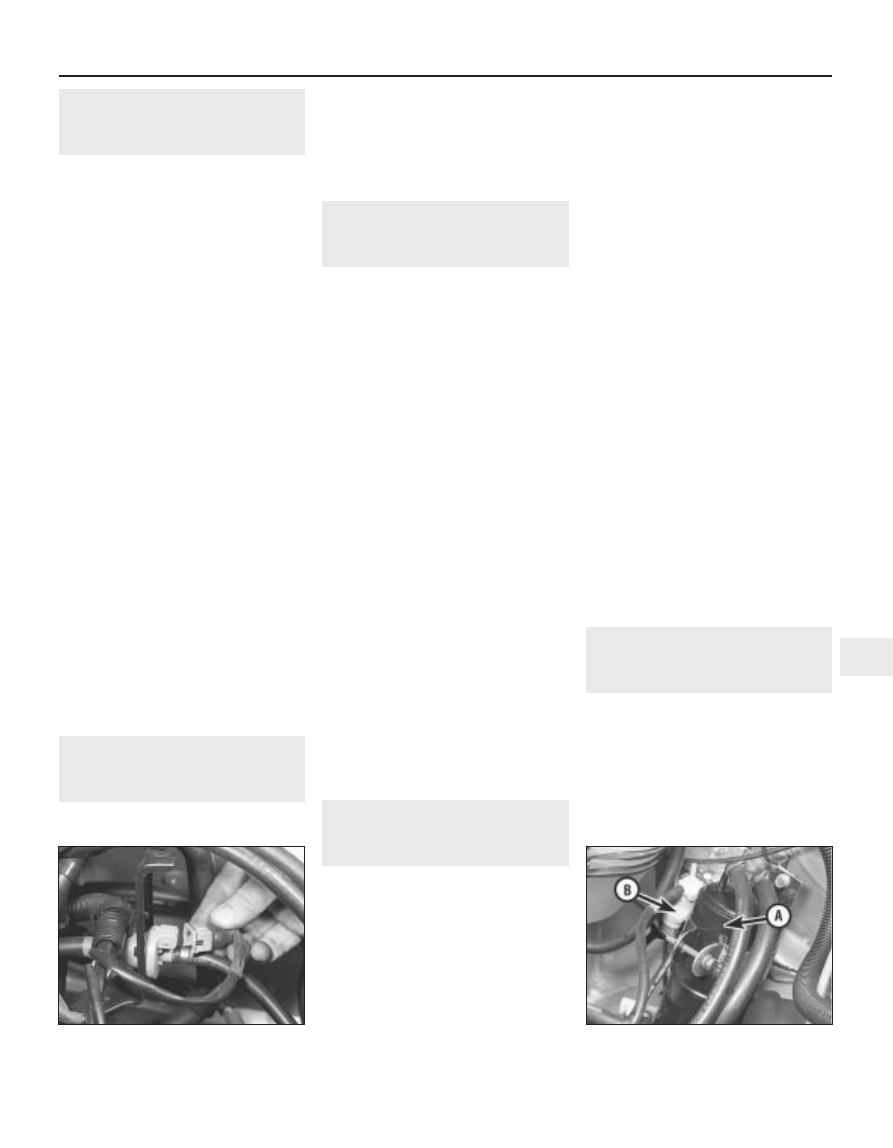

8.1 Fuel vapour recirculation system

carbon canister (A) and solenoid valve (B)