содержание .. 17 18 19 20 ..

Peugeot 205. Manual - part 19

XU series engines

3 On some early engines, both the upper and

lower bearing shells were of the same

thickness.

4 However, on later engines the main bearing

running clearance was significantly reduced.

To enable this to be done, four different grades

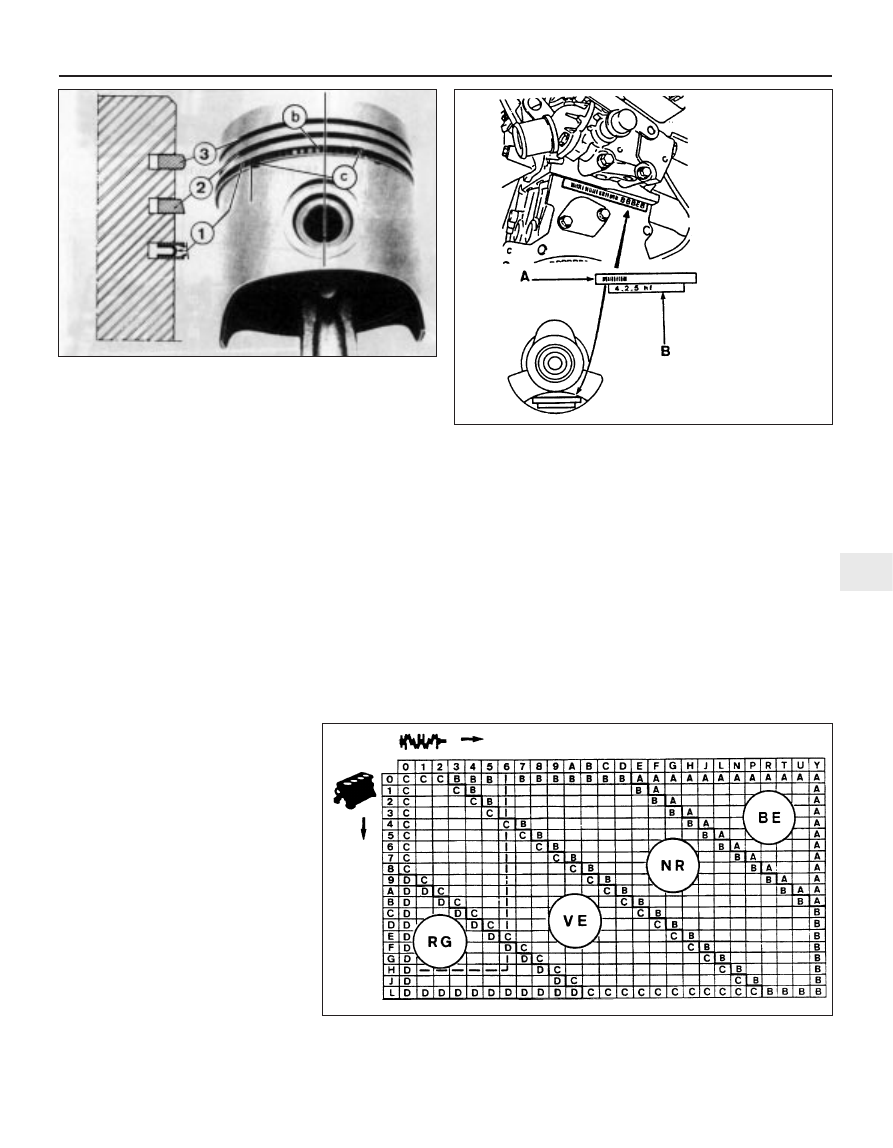

of bearing shell were introduced. The grades

are indicated by a colour-coding marked on the

edge of each shell, which denotes the shell’s

thickness, as listed in the following table. The

upper shell on all bearings is of the same size,

and the running clearance is controlled by

fitting a lower bearing shell of the required

thickness. This arrangement has been fitted to

all engines produced since mid-1994 and, if

possible, should also be fitted to earlier

engines during overhaul (see paragraph 11).

Bearing colour

Thickness (mm)

code

Standard

Undersize

Upper bearing:

Yellow

1.856

2.006

Lower bearing:

Blue (Class A)

1.836

1.986

Black (Class B)

1.848

1.998

Green (Class C)

1.859

2.009

Red (Class D)

1.870

2.020

Note: On later engines, upper shells are easily

distinguished from lower shells, by their

grooved bearing surface; the lower shells have

a plain surface.

5 On early engines, the correct size of bearing

shell must be selected by measuring the

running clearance as described under the

sub-heading below.

6 On engines produced since mid-1994,

when the new bearing shell sizes were

introduced, the crankshaft and cylinder

block/crankcase have had reference marks on

them to identify the size of the journals and

bearing bores.

7 The cylinder block reference marks are on

the left-hand (transmission) end of the block.

The crankshaft reference marks are on the

left-hand (transmission) end of the crankshaft,

on the left-hand web of No 1 crankpin (see

illustration). These marks can be used to

select bearing shells of the required thickness

as follows.

8 On both the crankshaft and block, there

are two lines of identification, a bar code,

which is used by Peugeot during production,

and a row of five characters (letters and

numbers). The first character in the sequence

refers to the relevant size of No 1 bearing (at

the flywheel/driveplate end) and the last letter

in the sequence refers to the relevant size of

No 5 main bearing. These marks can be used

to select the required bearing shell grade as

follows.

9 Obtain the identification character of both

the relevant crankshaft journal and the

cylinder block bearing bore. Note that the

crankshaft characters are listed across the

top of the chart, and the cylinder block

characters down the side (see illustration).

Trace a vertical line down from the relevant

crankshaft character, and a horizontal line

across from the relevant cylinder block

character, and find the point at which both

lines cross. This crossover point will indicate

the grade of lower bearing shell required to

give the correct main bearing running

clearance. For example, the illustration shows

cylinder block reference H, and crankshaft

reference 6, crossing at a point within the area

of Class D, indicating that a Red (Class D)

lower bearing shell is required to give the

correct main bearing running clearance.

Engine removal and overhaul procedures 2D•17

2D

12.10 Piston ring identification

1 Oil control ring

2 Second compression ring

3 First compression ring

b Oil control expander ring

gap

c Oil control scraper ring gaps

13.7 Cylinder block

and crankshaft main

bearing reference

markings - later XU

series engines

A Bar code (used in

production)

B Identification characters

13.9 Main bearing shell selection chart - later XU series engines

BE Blue (Class A)

NR Black (Class B)

VE Green (Class C)

RG Red (Class D)