Opel Mokka X (2019 year). Manual - part 13

198

Vehicle care

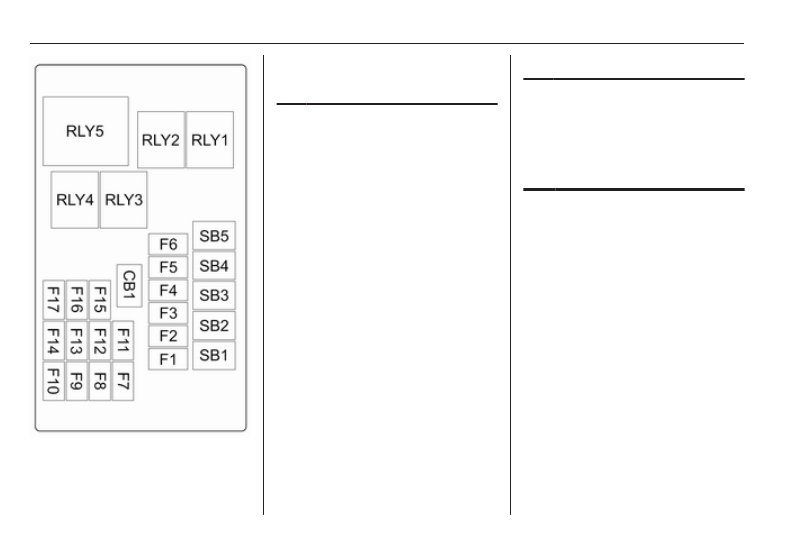

Mini Fuses

No. Circuit

1

Amplifier

2

All-wheel drive

3

–

4

Selective catalytic reduction

5

Selective catalytic reduction

6

Selective catalytic reduction

7

Selective catalytic reduction

8

Spare

9

Spare

10 Spare

11 –

12 Spare

13 –

14 –

15 Spare

16 –

No. Circuit

17 –

18 –

S/B Fuses

No. Circuit

1

DC/DC 400W transformer

2

DC/DC 400W transformer

3

–

4

–

5

–

6

–

7

–

8

–

9

–